Getting to Know the Vibro Sifter Parts

No matter what kind of process industries you're working in, a vibro sifter machine is a must-have for your business.

What is a vibro sifter? This type of device is also known as a vibratory sifter, vibrating sifter, or vibrating sieve machine. It's designed for sorting, grading, or scalping various applications from lab-scale to production-scale processes.

A vibratory sifter offers high efficiency and precision in separating your desired liquids or solids from a mixture. It can deliver high output rates with enhanced accuracy and product quality.

To ensure a great final product, you need a vibro sifter machine that is manufactured to be high-performance and efficient in its design and construction. This is what we're going to talk about today. Let's start with the vibro sifter parts.

What are the major parts of vibro sifter?

To make the machine run efficiently, you need a bunch of vibro sifter parts that work together to achieve the desired result of the production.

Let's walk through some crucial parts of vibro sifter that you need to be familiar with:

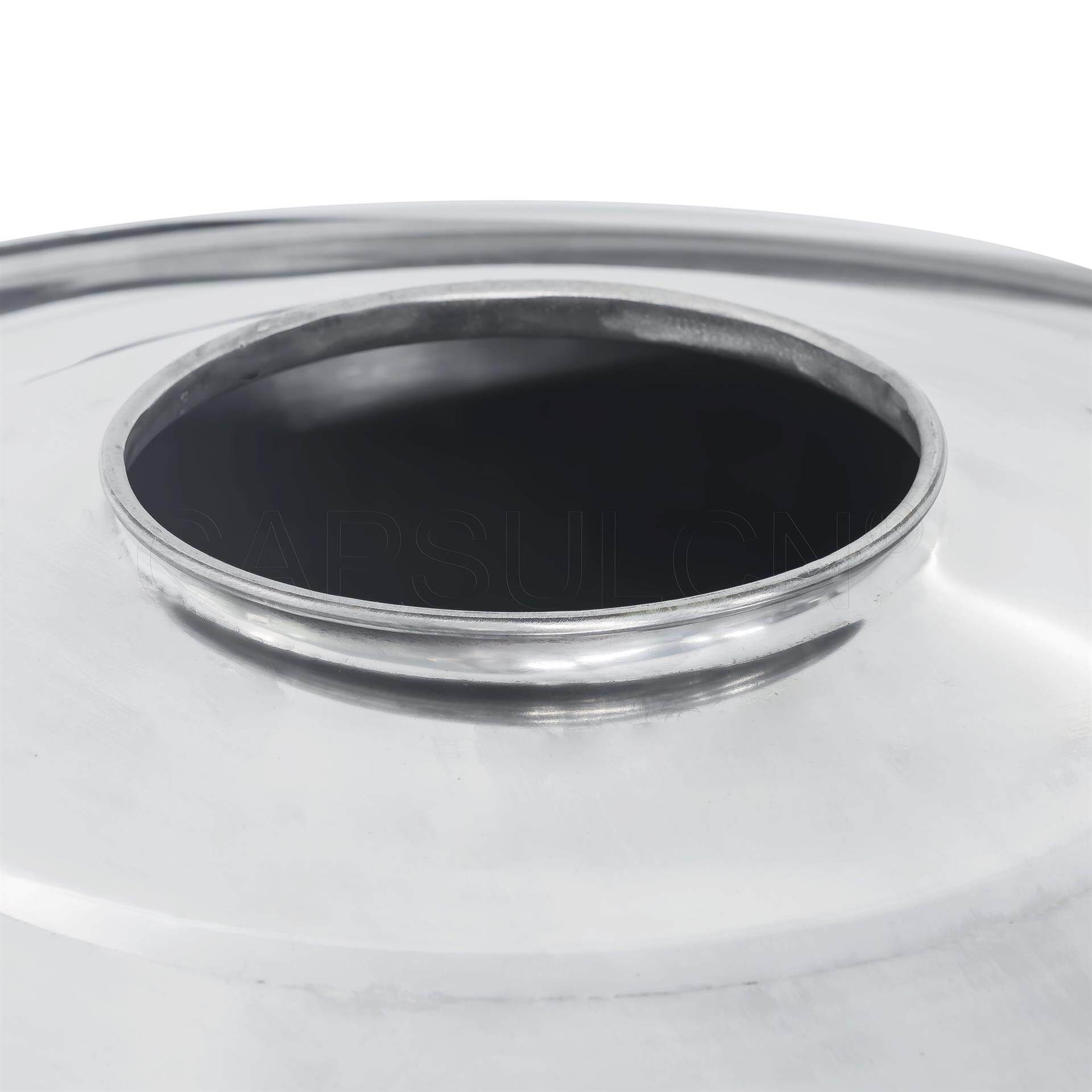

1. Dust cover

The dust cover is attached to the top of the vibratory sifter in this configuration. In most cases, it is crafted from stainless steel or another type of metal.

This component is designed with a hole as the inlet for feeding the ingredients to be processed. The dust cover works to keep the material from falling out of the machine when it vibrates. Also, it helps prevent cross-contamination that may occur.

Further, since the screen mesh is very delicate, the dust cover is used to prevent the mesh from coming into contact with any harmful external elements that could damage it.

2. Filter screen

A filter screen is one of the most important parts of vibro sifter. It plays a big part in the sifting process. The filter screen is made with a wire mesh that has a very fine, smooth surface. This ensures that the ingredients can be sieved in the most effective manner.

Also, the filter screen can help stop any leaks while processing materials. Depending on the configuration of your vibro sifter, the screen might come in a number of different sizes.

3. Wire mesh screen ring

This component comes in a circular shape. It's hemmed around the outer edge of the wire mesh screen. The screen ring is attached to the mesh using adhesive, allowing for enhancing the longevity of the mesh.

Also, the strong bonding ensures the wire mesh stays in place during material processing, even if the unit vibrates vigorously.

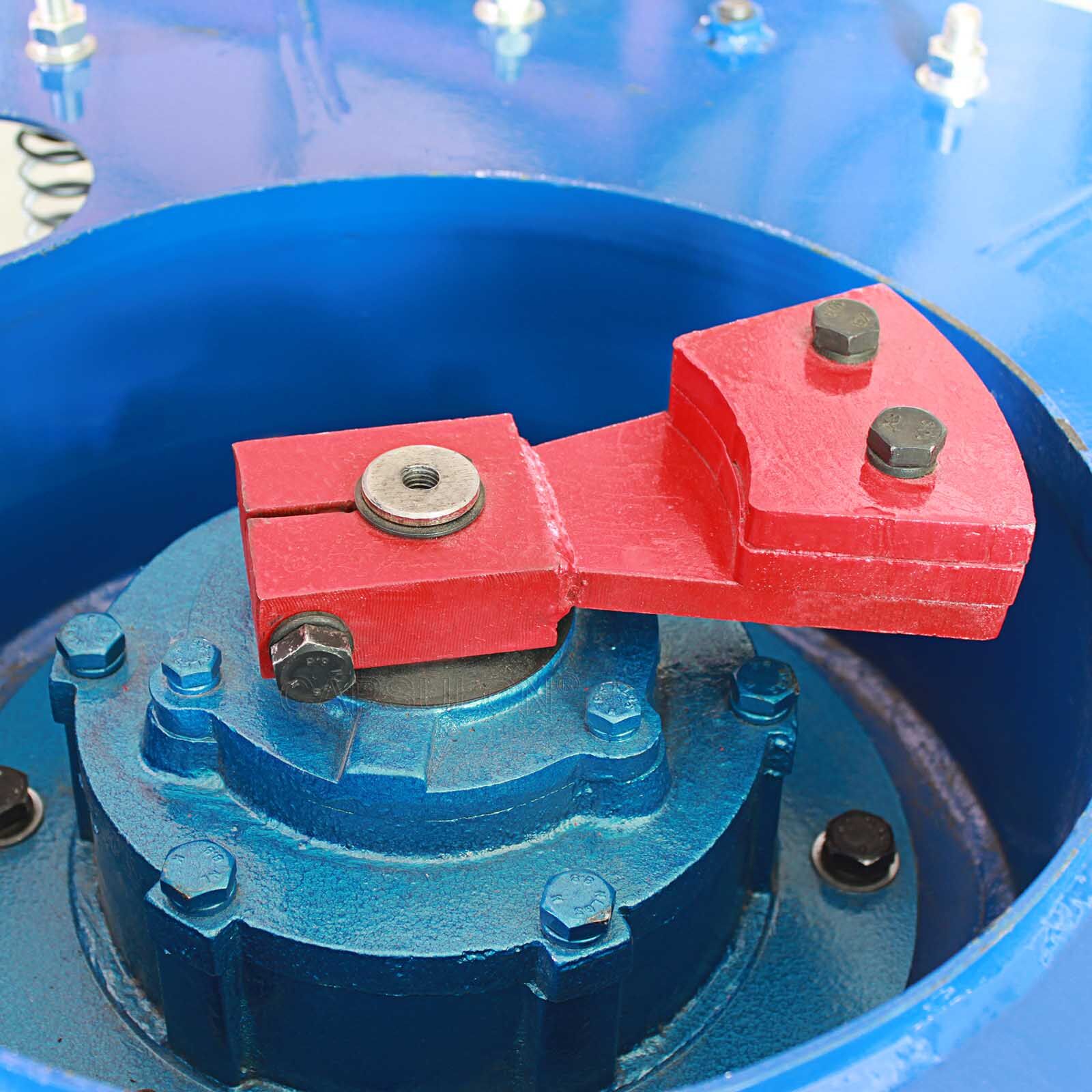

4. Clamp ring

As the name implies, a clamp ring also comes in a circular shape. This component is used to hold and secure the sieve decks and filter screens. Today, most vibro sifters feature quick-release clamp rings, allowing operators to assemble and disassemble the vibrating sieving machine without tools.

The clamp ring functions as a seal to protect the ingredients from falling out of the sieves. It also allows the vibro sifter to be dust-tight, keeping dust or contamination at bay, regardless of how intensely the unit is being shaken.

5. Bouncing balls, ball retaining rings, and ball tray

This set of components is also one of the crucial vibro sifter parts. They are positioned beneath a mesh screen or between screens.

The ball tray is typically a perforated plate sieve made of metal. It works to place and hold the bouncing balls and ball retaining rings.

The bouncing balls and ball retaining rings are available in a variety of sizes and food-grade materials, depending on your sieving purpose. The balls sitting in the retaining rings hit the screen by bouncing up and down so that the ingredients stuck in the mesh can fall off. This helps improve sieving accuracy and productivity.

6. Material outlet

The material outlet is a discharge chute where all graded and screened particles leave the machine. This component, welded together with the sieve deck, is placed at the bottom of a screen.

For materials containing more than two ingredients, the material outlets from top to bottom discharge the sieved particles from coarse to fine products.

7. Springs

When it comes to the major parts of vibro sifter, the springs should never be overlooked. They also play a big role in the process of sieving.

A vibratory sifter is often fabricated with multiple springs. These springs are used to hold the sieves up in the air. They enable the vibro sifter machine to move easily and freely when it vibrates. The springs also act as a damper, reducing vibrations so that the floor doesn't get damaged.

8. Electric motor

As one of the most important vibro sifter parts, this component functions as the powder source, letting the whole device do all its jobs without stopping. The motor is in charge of turning electrical power into energy that runs the unit.

The vibrating motion created by the electric motor allows ingredient particles to travel through the screens more quickly. By the way, the motor size of a vibro sifter can vary based on the design and size of the machine, as well as its output capacity.

How does a vibro sifter machine work?

Since you know the most important parts of vibro sifter, you may be interested in how a vibratory sieve machine works.

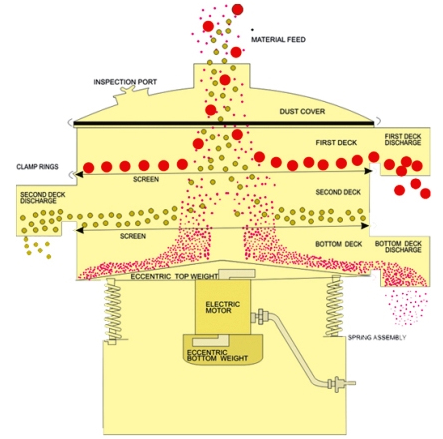

The working principle of vibro sifter is quite simple. The machine works on the principle of gyratory vibration to separate and grade materials based on particle sizes.

Powered by an electric motor, the vibratory sifter starts to vibrate as a result of the off-balance weight assembly. As the eccentric top weight rotates, it causes the sieves to vibrate in a horizontal plane. The vibrating motion pushes the oversize particles across the screen and out to the edges.

At the same time, the eccentric bottom weight rotates. It causes vibration in the vertical direction by creating a tilt on the sieves. The motion allows the most undersized particles to travel through the mesh.

During the vibration, the particles are separated and sorted. Then, they leave the machine through different discharge chutes when the sieving process is done.

Final word

All of the parts of vibro sifter work together to make it easy to separate, scalp, or grade your materials. To find a quality vibro sifter, you need to know what each part is and how it works. This article has provided a solid introduction to vibro sifter parts, allowing you to begin making informed purchasing decisions. If you want to learn more information about its suppliers, feel free to check this article, and you will learn 5 top vibro sieve manufacturers.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche