Understanding The Vibro Sifter Machine Working Principle

Have you ever wondered what sifting is? The sifting process is a straightforward method for sorting and separating particles of varying sizes. It's often referred to as the foundation of particle size technology.

Why is sifting still so widely used today?

- The first reason is that the process is easy to understand. It separates materials into several fractions based on their particle sizes.

- Second, the sifting technique has been around for centuries. It can date back to the times of ancient Egyptians when people used it to separate grain.

- Finally, the technique has been proven to be a cost-effective option in the processing industry.

So, what tools do you need to complete the sifting process? The answer goes to sifters. Today there are many different types of sifters out there. This article will explore one of the most popular varieties - the Vibro Sifter.

What is a vibro sifter machine?

A vibro sifter machine is also known as a vibratory sifter. It's a device used for sifting or separating various types of materials based on their particle sizes.

Vibro sifters make use of vibratory or gyratory motion to deliver a separation, scalping, and grading process. They're suited to all applications in the pharmaceutical, food, and chemical sectors, as well as many other industries.

Vibro sifter machines are designed to vibrate about their center of gravity. They can achieve vibrating motion across multiple planes using a specially made vibratory or gyratory motor. The motor comes with eccentric weights at the top and bottom ends of the motion-generating component.

However, these devices see their most common application in single-pass, low-volume work processes. This makes the vibratory sifter a cost-effective option. The equipment may be what you've been looking for if you're just getting started with sifting and have low-capacity requirements for the process.

What is the vibro sifter machine working principle?

Before learning how to use a vibro sifter, you need first to get a grasp on how it works.

The vibro sifter machine working principle is unique yet simple. That's one of the reasons why this type of machine is regarded as being so helpful for the pharmaceutical business.

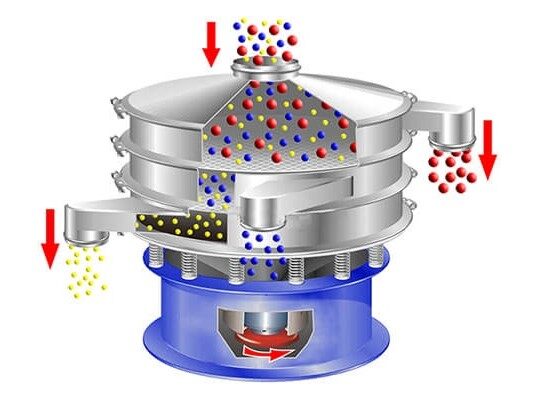

The vibro sifter machine mainly works on the principle of gyratory vibration. These machines help to separate materials according to the particle sizes of the ingredients. Now, let's dive into the vibro sifter machine working principle to see how it actually operates.

Put the ingredients you need to separate into the sifter via the feed inlet on the dust cover of the equipment. Check to see that the dust cover, mesh screens, sieve decks, and bottom deck are all secured with the clamp rings at the same time.

Turn on the power supply at this time. This supplies electrical energy to the motor, enabling it to vibrate as a result of the out-of-balance weight assembly.

After that, the sieving machine will start vibrating very hard. The materials loaded from the feed inlet travel through the screens based on their particle sizes. The number of sieve decks and screens depends on the varieties of your materials to be sifted. The sieves are held up by springs so that vibrations don't go all the way down to the floor.

The weight at the top of the motor shaft rotates in a plane close to the assembly's center of mass. The rotation of the top eccentric weight causes vibration in the horizontal plane. The vibrating motion forces the materials to move across the screen to the edges, allowing oversize particles to be discharged quickly.

The eccentric bottom weight rotates under the center of mass. This tilts the screen and makes it vibrate in the vertical and tangential planes. Increasing the vertical component of motion makes it easier for materials to move across the surface of the screen. This lets the most undersized material pass through the screen.

What are the major parts of vibro sifter?

Now that you have a rough idea of the vibratory sifter principle, you might be curious about the critical vibro sifter parts make the machine run.

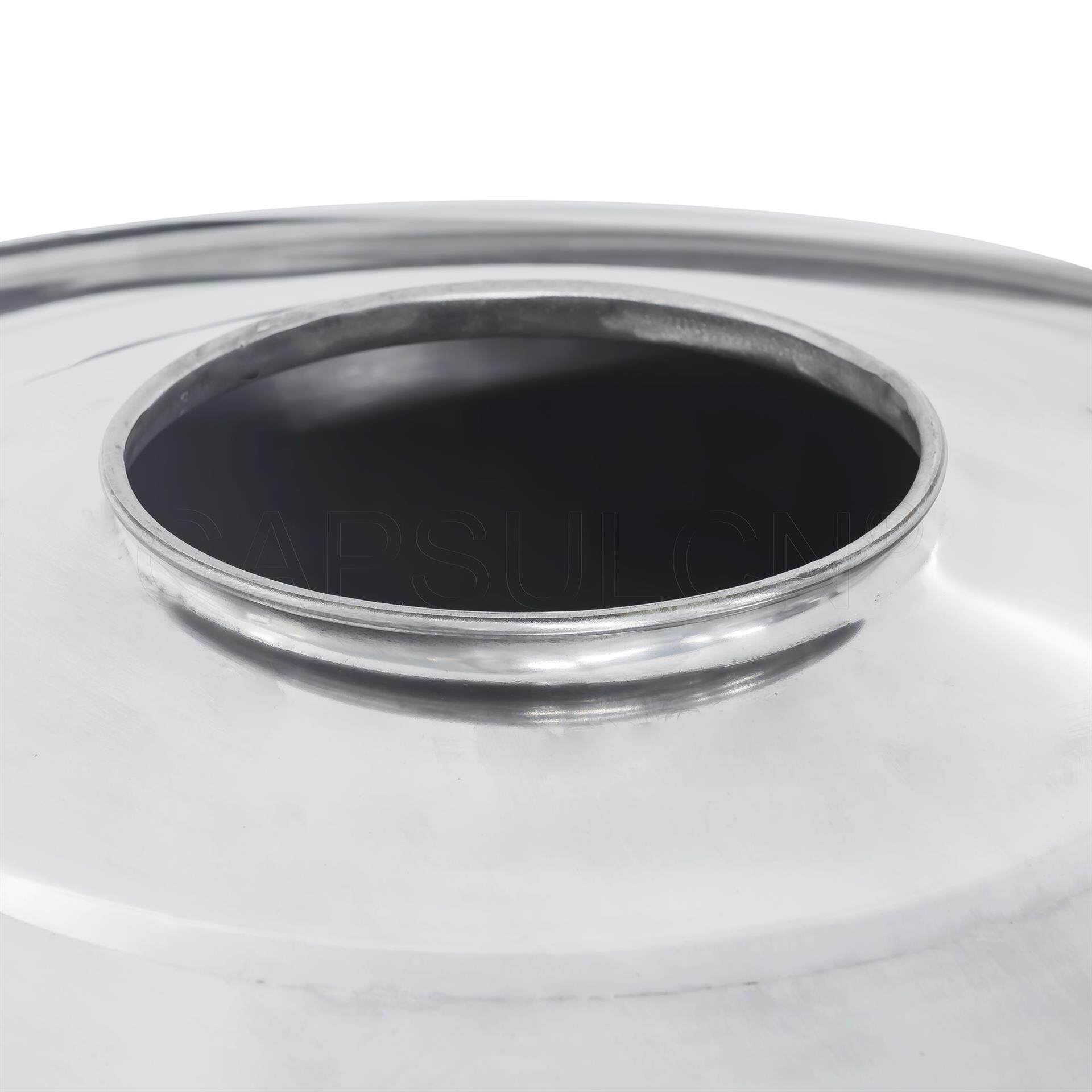

1. Dust cover

The dust cover is mounted at the top of the sieving machine. It's typically fabricated from stainless steel or other metal.

This component works to keep the material being processed from falling out of the machine when it vibrates. It also helps prevent cross-contamination that may occur. Further, since the screen mesh is very delicate, the cover is used to keep the mesh from coming into contact with outside elements that could damage it.

2. Screen

A screen plays a big part in the vibratory sifter principle. It's made with a wire mesh with a fine, smooth finish. During processing, the screen allows small particles to be sifted easily.

Also, using the screen can help stop any leaks while processing materials. The screen comes in a variety of sizes, depending on how the sieving machine is built.

3. Clamp ring

As the name implies, the clamp ring comes in a circular shape. It's used to hold and secure the sieve decks and wire mesh screens. Today, most vibro sifters feature quick-release clamp rings, allowing operators to assemble and disassemble the sieving machine without tools.

The clamp ring functions as a seal to protect the ingredients from falling out of the sieves. It also allows the vibro sifter to be dust-tight, keeping dust or contamination at bay, regardless of how intensely the unit is being shaken.

4. Bouncing balls, ball retaining rings, and ball tray

This set of components is also an indispensable part of the vibratory sifter principle. They are mounted under a mesh screen or between screens.

The ball tray is often a perforated plate sieve made of metal. It's used to place the bouncing balls and ball retaining rings.

The bouncing balls and ball retaining rings are available in a variety of sizes and food-grade materials, depending on your sieving purpose. The balls sitting in the retaining rings hit the screen by bouncing up and down so that the ingredients stuck in the mesh can fall off. This helps improve sieving accuracy and productivity.

5. Material outlet

This is a discharge chute where all graded and screened particles leave the machine. This component, welded together with the sieve deck, is placed at the bottom of a screen.

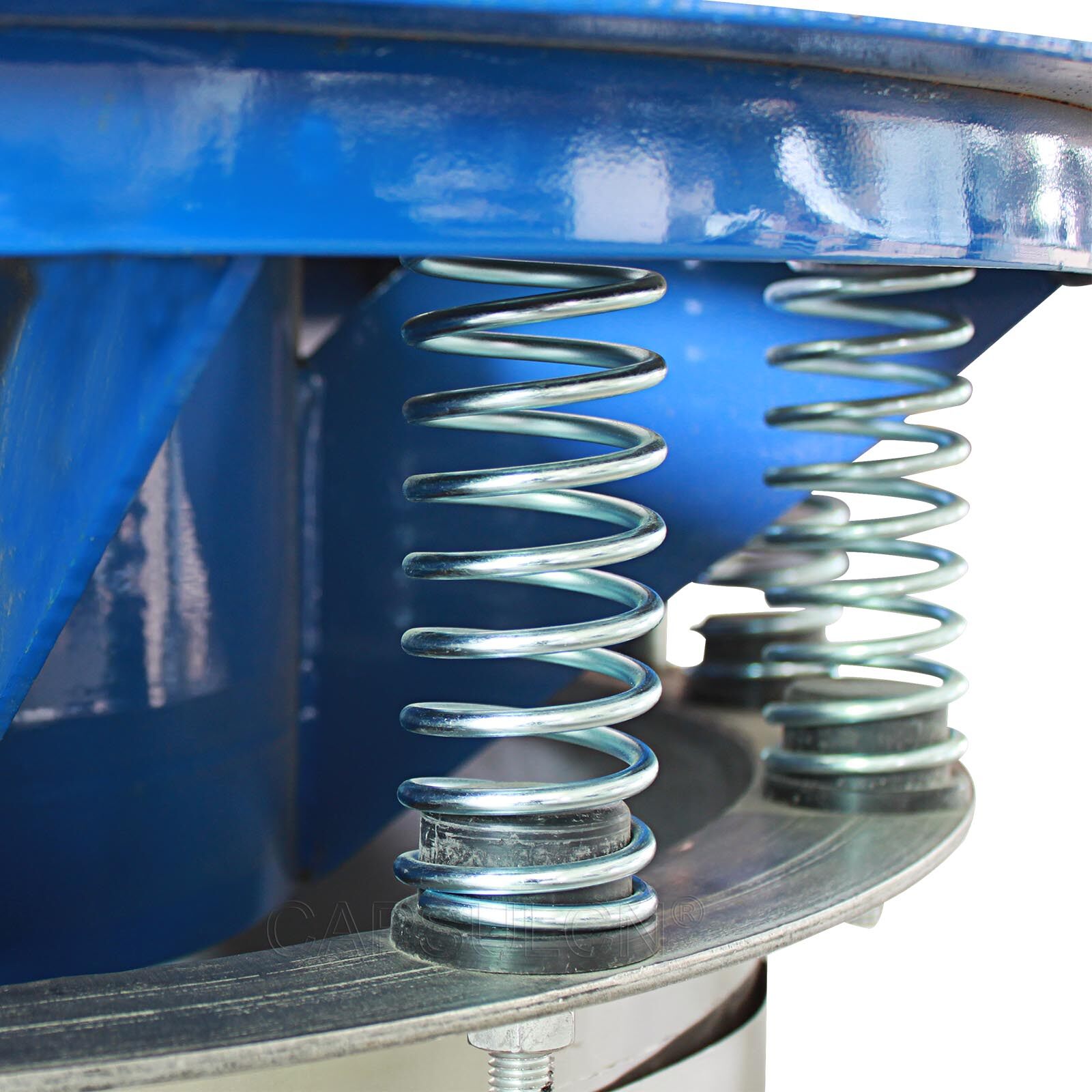

6. Springs

Multiple springs are used to hold the sieves up in the air. They enable the vibro sifter machine to move easily and freely when it vibrates. The springs also act as a damper, reducing vibrations so that the floor doesn't get damaged.

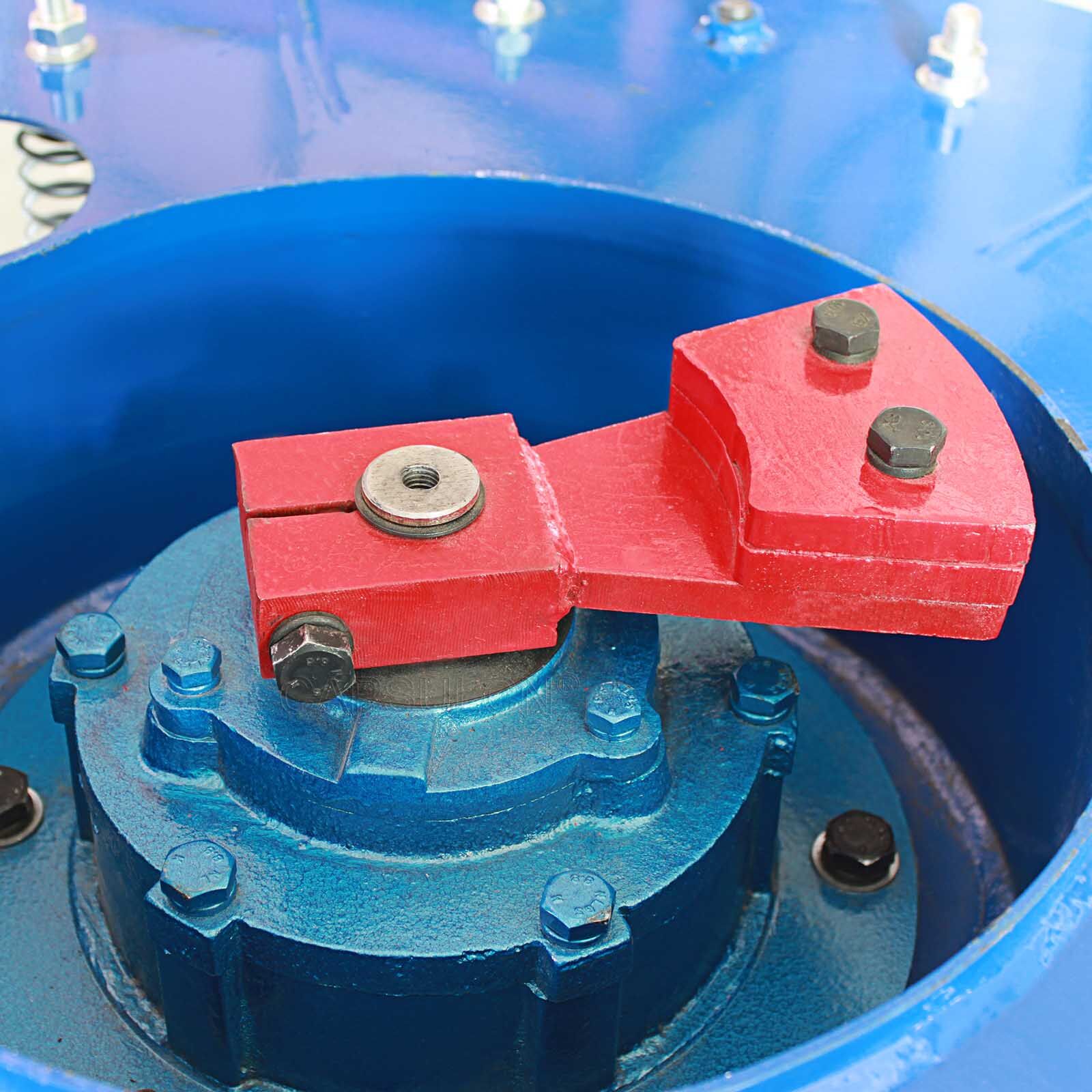

7. Electric motor

This component is also crucial to the vibratory sifter principle. It functions as the powder source, letting the whole device do all its jobs without stopping. The motor is in charge of turning electrical power into energy that runs the unit.

The vibrating motion created by the motor allows ingredient particles to travel through the screens more quickly. By the way, the motor size of a vibro sifter can vary based on the design and size of the machine, as well as its output capacity.

Conclusion

The vibro sifter is an effective piece of industrial equipment that separates and sieves the ingredients to the desired particle size. If you're going to invest in a sieving machine, this article can help you fully understand the vibro sifter machine working principle and important parts before making the final decision.

Read more:

Top 5 Vibro Sifter Machine Manufacturers: A Complete Guide

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche