What are the Advantages of Wet Granulation

The granulation process is vital in the pharmaceutical and packaging industry. It helps in making various forms of solid dosage medication. Most tablets are first in powder forms. So, there is a need to repackage them into the shapes they take in different pharmaceutical brand packages.

The process that helps in creating these industry-standard products is granulation. In this article, you will learn more about this process and the advantages and disadvantages of wet granulation. You will also get a bonus section on top-quality wet granulation machines available in the market.

Wet Granulation Procedure

Granulation is of two types: wet and dry. Indeed, other methods also exist, such as melt granulation and spray drying, and some pharmaceutical companies use them. Yet, wet and dry granulation are the most popular in the industry. Both procedures involve making powder particles stick together to produce solid dosages - certainly there exists difference between dry and wet granulation.

Dry granulation is the cheaper of the two. It is the best method for making drugs when there is a critical need for temperature and moisture control. It involves compacting the dry powder granules into one another during the granulation process.

The result of this approach is densification. But wet granulation involves using water or other fluids in the granulation process. The material's properties for making a particular drug determine the fluid choice.

Wet Granulation Superiority

In the wet granulation process, excipients are the extra materials in a drug apart from the active ingredient. It includes additives for colors and texture. Some help bind the tablet's particles together, while others preserve them.

Wet granulation does not need special excipients, while dry granulation usually needs such inputs. It is necessary to compensate for its deficiency. Thus, the chances are high that the drugs produced through this procedure will be more potent.

One of the major reasons wet granulation is popular is its content uniformity provision. Professional drug-makers do not want to make medication that appears substandard. So, they place a high value on the uniformity of their tablets. Wet granulation makes this process easier, especially when dealing with soluble low-dose medication. Wet granulation often struggles to achieve homogeneity with such drugs.

Drugs with poor dissolution rates are nightmares to drug makers. They take time, and manufacturers have no choice but to wait until the process ends. But wet granulation helps to overcome this challenge by speeding up the process. Increasing these drugs' dissolution speed makes the formulation and production procedure faster.

While producing, handling, transporting, and storing drugs, there is a chance of segregation of components. This occurrence is possible, especially when dealing with a uniform powder mix.

But, wet granulation reduces the chances of this event taking place. Thus, it limits variability in the form of inter-batch and intra-batch differences. This advantage increases the professionalism of pharmaceutical companies, enhancing their reputation in the industry.

5 Advantages of Wet Granulation

Wet granulation is the oldest and the most population technique in the pharmaceutical industry. Below are some of the advantages of wet granulation:

1. Masking of Tabulation Deficiencies

Creating a tablet with a perfect shape can be challenging, especially when the material lacks such qualities. Yet, with the aid of wet granulation, this is achievable because this process masks the defects of the materials used in the production of the drug.

But, dry granulation will submit to the characteristics of the material. Thus, the tablets produced through wet granulation are usually more spherical. They also often have better flow properties.

2. Better Compressibility

One of the challenges of dry granulation is that it usually leads to the use of high pressure during compression. No pharmaceutical products manufacturer will face this problem with wet granulation.

This procedure offers better compressibility, thereby cutting out the need for high pressure during compression. This method saves time and effort in aspect. Moreover, it extends the life of the machine by reducing machine wear.

3. Aids Tablet Coating

Due to factors such as the smell of the active ingredient, tablet coating is sometimes necessary in the pharmaceutical process. Yet, it is a procedure that takes place after the completion of the manufacturing process.

So, dry granulating will not be effective at that point. Instead, wet granulation makes this procedure easy because the tablet remains malleable for post-processing operations. This is one of the reasons many pharmaceutical companies invest in wet granulators despite their higher cost.

4. Reduces the Risk of Air Entrapment

One of the enemies of tablet compressibility is air entrapment. Once air is trapped between the particles of the powder form of the drug, it becomes difficult to compress. Meanwhile, a tablet loses its professional appeal without excellent compression. Thus, pharmaceutical companies often try their best to prevent this situation.

The good news is that wet granulation offers an effective solution in this aspect. This is one of the reasons this procedure offers higher powder compressibility in comparison to dry granulation.

5. Limits the Level of Dust

The last thing pharmaceutical product manufacturers want is the contamination of drugs during the production process. Drugs are meant to heal people and not make them sick. One of the ways to avoid contamination during this process is the prevention of dust. Wet granulation reduces the chances of exposure to dust, and this also protects the employees involved in the process.

Demerits Of Wet Granulation

Despite the many advantages of wet granulation, it also has limitations. Here are some of them:

1. The Process is Complex Without Machines

Some pharmaceutical companies opt for dry granulation and other methods because wet granulation can be complex. The technique is not easy, especially in the absence of the right equipment. So, whoever is planning to take advantage of the benefits of this procedure must be ready to invest in machines. With the aid of top-class wet granulators, the process is seamless. Without them, it is best to consider other approaches.

2. It is More Expensive

The cost-effective attraction of dry granulation is one of the reasons it appeals to many companies. Wet granulation requires more capital, and that is the reason startups and small companies in the industry avoid it. Yet, any pharmaceutical firm that wants to move on to the next level has to invest in such machines. They are always worth the extra cost.

3. It Requires More Effort And Energy Consumption

Pharmaceutical companies without a steady supply of energy will struggle with this technique. It requires a stable supply of electricity to power the machines for carrying out this process. So, it is advisable that a company is willing to invest in renewable sources of energy before considering this method. This is particularly important to companies that do not have access to a stable electricity supply. Yet, the fact that most such firms operate in cities will help solve this challenge.

4. Not Suitable For Moisture Control

When dealing with moisture-sensitive materials, wet granulation is not the best approach. Yet, the lack of plenty of such substances in the pharmaceutical process ensures that this is not a significant challenge.

Top-Class Granulation Machines

It is good to know the advantages and disadvantages of wet granulation technique. It will enable you to deal with the challenges. The complex process of wet granulation requires excellent machines for its success. Without them, the process becomes long and demanding. So, any pharmaceutical company that wants to take advantage of the many benefits of this method needs wet granulators.

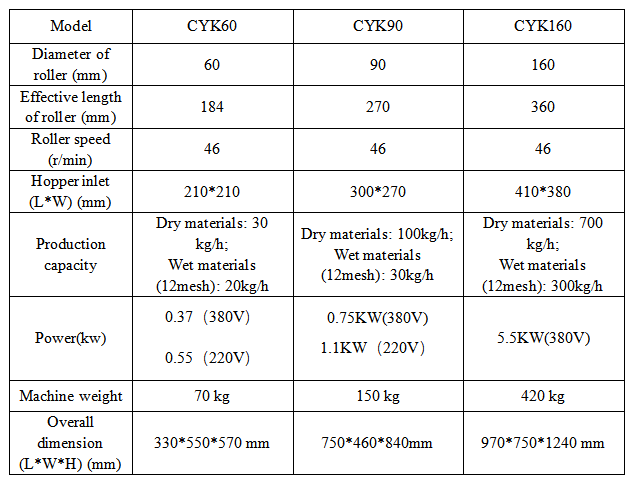

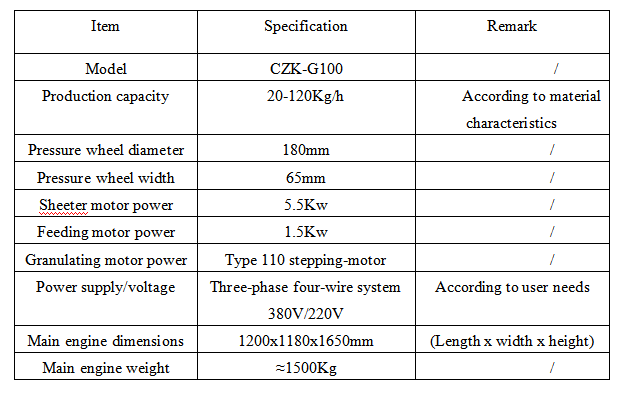

The good news is that iPharMachine has some of the best products that make the process seamless. CYK Series Oscillating Granulator and CZK-G100 Granulator are two of the top granulators of the company. They have the following features:

1. CYK60-90 Granulator

- Its advance granulating method saves energy.

- It has a long service life.

- It has a simple and reasonable structure despite its sophistication.

- It is suitable for the chemical, food, and pharmaceutical industries.

2. CZK-G100 Dry Granulator

- It has a simple design that makes it simple to operate.

- It is energy-saving, thanks to its advance granulating method.

- It offers uniformity and compressibility.

- It has a sturdy design for longevity.

Final Words

We have highlighted the advantages and disadvantages of wet granulation method. It is obvious that wet granulation has several benefits that make it superior to dry granulation. It offers better uniformity and perfect shapes. Thus, it is not surprising that it remains the oldest and most popular granulation method. We also identified some of the disadvantages of this process. They include its demanding time and energy.

Besides, the process is more complex in comparison to dry granulation. Yet, you can navigate these challenges by investing in high-grade wet granulators. CYK60-90-160 Granulator and CZK-G 100 Granulator by iPharMachine have the features you need in a top-class granulator. Moreover, the company has a reputation for producing top-quality pharmaceutical equipment and machines. So, investing in any of these machines guarantees that you will get value for your money.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche