What is a Labeling Machine: An Ultimate Guide

When in a supermarket, have you ever wondered how those colorful labels are applied to the goods in so many different ways? Actually, all this is thanks to the labeling machine which is an unsung hero in the packaging world . Now Let's take a deeper look on the labeling machine and feel its charm.

What is a Labeling Machine?

If you are in the field of packaging, you must have heard about labeling machine. So what is its main function? Make sure the label can be correctly attached to the product every single time. From modest medicine bottles to high-end cosmetic containers, labeler machines play such an important role in making packaging look more refined and professional.

Why are Labeling Machines so Important?

In fact, the influence of the labeling machine far exceeds simple product identification. This machine can offer you many benefits in various aspects.

1. Promote Brand Awareness

In essence, the label on every product is a branding tool. The manufacturer cleverly prints its brand name on the label, and then uses a labeling machine to attach the label to its products. In this way, when consumers walk into the supermarket and see these dazzling labels, they also understand the unique personality and the story behind each brand. In the long run, your brand awareness and recognition will get improved.

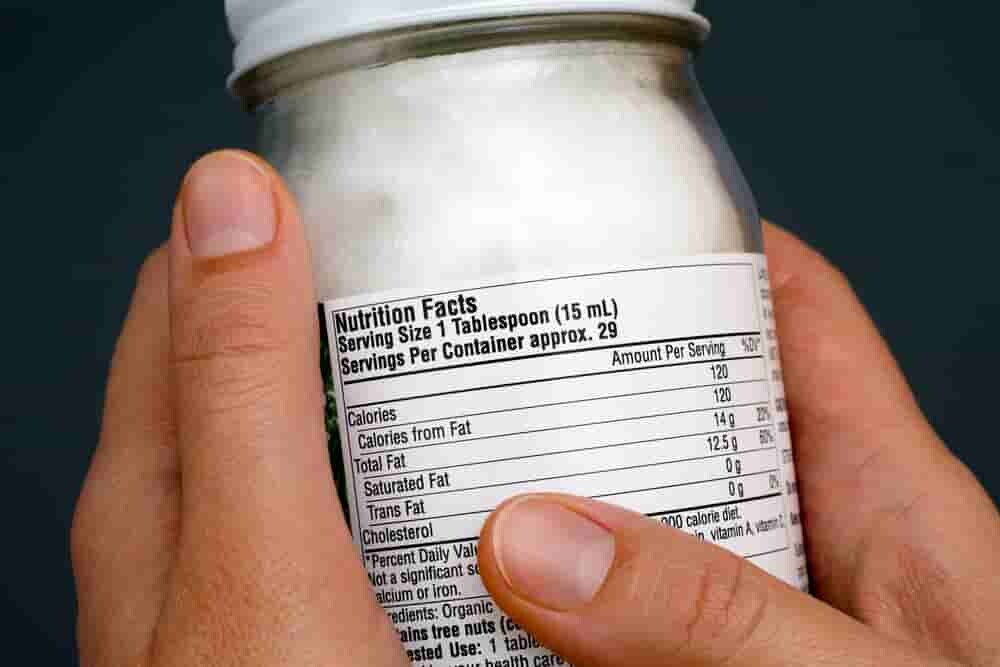

2. Provide Key Information

In the pharmaceutical industry, product information is critical to consumers. The labels made by labeling machines are more than just logos. They are also information centers, providing important details about the dosage, instructions for use and expiry dates of medicines. In a healthcare setting, accuracy is super important. These labels enable healthcare professionals and patients to make more informed choices.

3. Ensure Batch Differences

The production process normally involves many batches, so how do you distinguish which batch a particular product belongs to? This is where the labeling machine is needed. Labeling machines play a key role in distinguishing products. By assigning different labels to each batch, labeling machines help improve warehousing and distribution efficiency. This is not only for faster product identification, but also for maintaining order in complex production environments.

What are the Different Types of Label Applicator Machines?

Label applicator machines come in various types, and they are designed to meet different packaging needs. Let’s check out which are the most common labeling machine types.

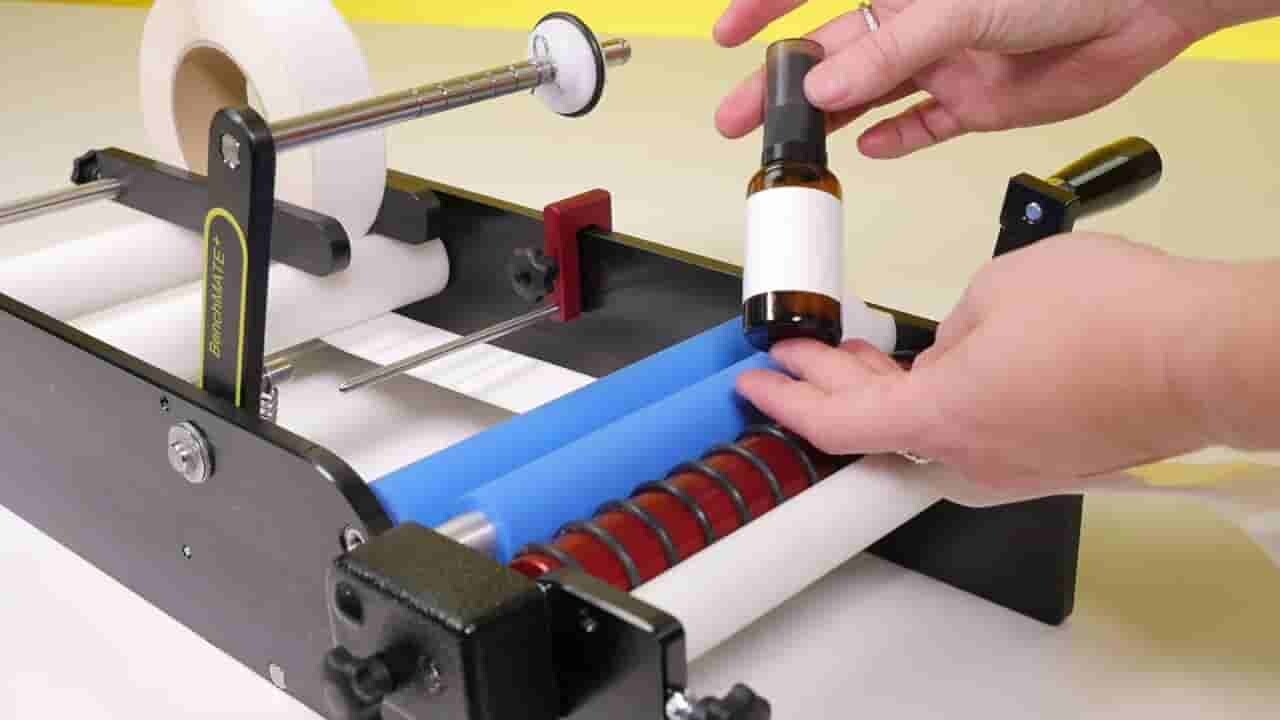

Manual Label Applicator Machine

Want to equip your product line with a label application machine but don't have a big budget? Check out the manual labeling machine. It is for sure an affordable solution.

(Image Source: Jet City Label)

Main Features:

- Manual labeling machines are economical and suitable for small businesses with limited resources.

- It is a user-friendly machine that requires little training to operate.

- Manual labeling machines can handle containers of all shapes and sizes.

Applications:

Manual labeling machine is most suitable for enterprises with low labeling requirements or small-sized businesses. For example, it can be used to apply labels on handmade products or small batch production.

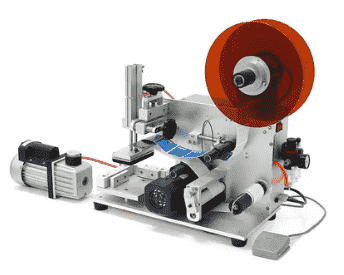

Semi-automatic Label Applicator Machine

If you are planing to expand your production scale, there will be an increasing need for automation in your production line. At this time, a simple manual labeling machine may not be able to fulfil your needs. Semi-automatic labeling machine becomes a better choice now. In terms of applying labels, it can perfectly combine the precision of manual operation with the efficiency of automation.

Main Features:

- Semi-automatic labeling machines are usually started by a switch or foot pedal. This provides the operator with a degree of control while increasing labeling efficiency.

- This machine can effectively label different sides of medicine containers.

- The use of electronic control mechanisms allows flexibility in handling various label types and adapting to different container sizes.

Applications:

Semi-automatic labeler machine is ideal for companies with moderate production volumes but require more consistent labeling, especially when different products or different labeling locations are involved.

Automatic Label Applicator Machine

The automatic label applying machine represents the highest level of labeling automation. This kind of fully automated machine operate can with little or no human intervention. At the same time, it offers superior labeling speed and accuracy.

Main Features:

- The automatic labeling machine is designed to work at high speed. So, it can cater to the needs of large-scale production.

- It can seamlessly integrate into a packaging line, which ensure a smooth production process.

- The machine guarantees precise label placement, which enhances the consistency throughout the whole production line.

Applications:

The automatic labeling machine is perfect for big manufacturing companies involved in mass production.

Where Can Labeling Machines Shine?

1. Pharmaceutical Industry

In the pharmaceutical field, labeling machines play a vital role in ensuring that the information on medicine bottles is accurate and clear. The labels on medicine are the best proof that they meet the industry's exacting standards.

In addition, the labeling machine provides an anti-counterfeiting seal for product safety, so that patients can take the medicine with confidence.

More importantly, the labeling machine makes the tracking system in the pharmaceutical supply chain more complete. Each label is like a digital fingerprint, allowing the company to monitor the transit of each medicine bottle.

2. Food Industry

Consumers are paying more attention to transparency and safety when choosing food products, so labeling machines are becoming more important to the food industry. They play a vital role in revealing the specific ingredients and allergens of foods. Labeling machines increase consumers' trust in food production companies by applying clear and real labels on products.

3. Cosmetics Industry

(Image Source: HERMA)

In the cosmetics world, the label is not only the display of product information, but also one of the important factors determining the appeal of the product to consumers. The labeling machine can embellish lipstick tubes, perfume bottles and skin care products with exquisite charm.

Labeling applicators create labels for products that list specific ingredients and instructions for use, which ensures that each product meets the regulatory standards of the cosmetic industry.

Labeling Machines You Might Be Interested In

As a leading manufacturer of packaging machinery, iPharmachine provides an extensive selection of labeling machines.

Before sold, each iPharmachine machine undergoes thorough testing to guarantee top-notch quality. Whether you require a semi-automatic labeling machine or a high-speed fully automatic one, iPharmachine has the ideal solution for you.

Here is a compilation of the most sought-after label applicator series by iPharmachine.

1. NCT-21100 Automatic Bottle Labeling Machine

FEATURES

- Advanced PLC control system is adopted to ensure stable and high speed operation of the machine.

- The operating system is controlled by touch screen, making it easier for users to change parameters.

- The labeling machine can adapt to various object shapes.

- Adopt precise screw adjusting mechanism.

- The synchronous chain mechanism ensures smooth and accurate calibration.

- Using advanced pneumatic coding technology, which ensures clear printing of batch numbers and expiration dates.

- The transmission type rolling bottle system ensures secure labeling.

- Made of high quality materials such as stainless steel and aluminum alloy.

2. MT-60M Semi-automatic Labeling Machine

FEATURES

- This semi-auto model can label up to 60 items per minute.

- The label header of this machine can be flexibly adjusted to meet various needs.

- Excellent labeling effect, the label it make can be free of wrinkle and bubble.

- Reliable PLC and sensor assemblies provide the best labeling performance.

- It can run independently or combined with the production line.

- Modular design makes it easy to maintain, and the cost is lower.

- Equipped with encoder to print information such as batch number and date of production.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche