What is a Ribbon Blender in Pharmaceuticals?

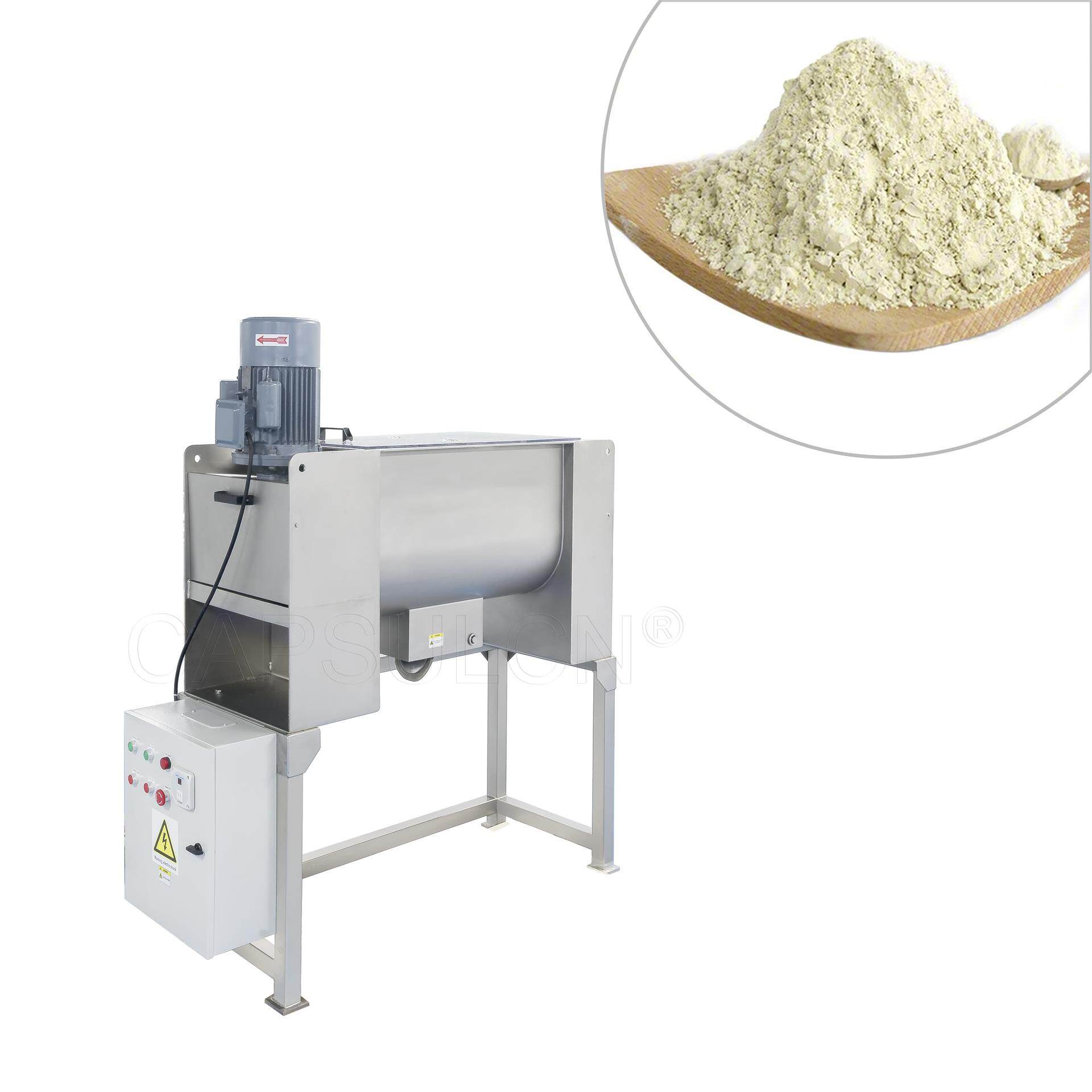

A powerful industrial tool used for mixing or blending large quantity content is a ribbon blender. The blender got the name because of its thin metal mixers in a ribbon shape. These are the main parts that conduct the blending of the content.

Besides, ribbon blenders have various applications in manufacturing. It is best used to manufacture medicines, chemicals, liquor, rubber, agricultural goods, etc. However, it is always the right thing to check the benefits of a ribbon mixer before buying it.

So, keep reading this article and learn about ribbon blenders and different industries where you can use them.

What Is A Ribbon Mixer?

Ribbon blenders are suitable for blending solids, dry powders, and semi-liquid materials. Both inner and outer ribbons offer efficient and economical blending. Furthermore, ribbon blenders are cost-effective and versatile options for various industries.

Read More:

Different Types of Mixers in Pharmaceutical Industry

V Mixer VS Ribbon Blender: Know the Difference

Conditions For Ribbon Blender

The ribbon blending machine needs a completely clean, dry, lit, and ventilated room for installation. Besides, a flat and stable surface is a must for the machine to be installed. Check that the power supply is functioning properly and that the machine is properly grounded before turning it on.

Please ensure the device hasn't been damaged during transport by thoroughly inspecting it before use. The seals on the mixing cabinet and stirring paddle should be cleaned. Also, ensure the belt's freedom of movement, the condition of the electrical components, and the stirring paddle.

Next, confirm the stirring paddle does not run into the cabinet wall when the machine is on. Additionally, ensure the bearing temperatures remain below 60 degrees Celsius even after the machine has been working for a while.

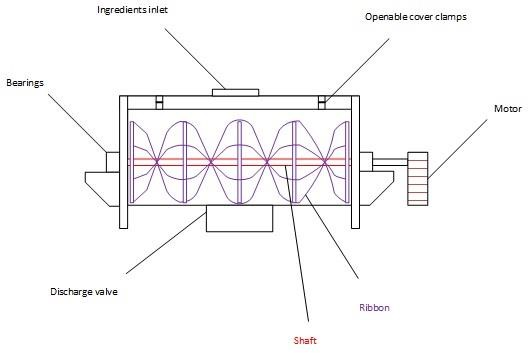

Principle Of Operation

How does a ribbon blender work? Ribbon blenders have two parts mounted on a central shaft. The design helps in appropriately mixing the material both inwards and outwards. Overall back and forth motion of materials that are blending creates the convective mixing pattern.

Moreover, the ribbons have gap tolerances between mixer walls. In some situations, these are designed with soft material wipers. Besides, these help in keeping the product from building on the sides.

A drive mechanism mostly comprises a belt drive to transmit powder between the gearbox and motor. This design uses flexible belts or pulleys for expected speed and torque. It helps in specific mixings. Nowadays, many manufacturers are using direct drives via gear motors using motors with a low inertia rotor to match the gearbox unit.

How To Reach Good Homogeneity With A Ribbon Blender?

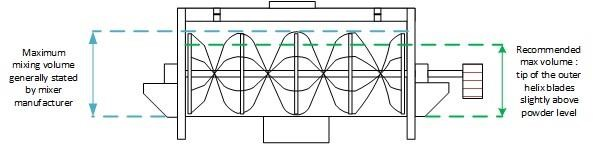

The ribbon mixers generally take a mixing time of up to 3-5 minutes. Ribbon blenders have a reputation for taking a while to combine; thus, some operators mix for 10-15 minutes. If there is a long mixing time, alert the producer that the mixer is not operating at its best. It is necessary to warn when there is no particularity of the mix.

The following operating parameters affect the mixer performance or the amount of time it takes to achieve the desired homogeneity:

- Batch size for mixing: 70–80% of the mixer's entire volume. Visually, the top of the blades must be slightly above the level of the goods, and there must always be some headroom to the top cover. Overloaded ribbon blenders are a very prevalent issue that significantly reduces their performance. A ribbon blender should not be underfilled. It is because the powder level needs to reach the inner ribbon in order to be moved and subsequently mixed.

- Mixing Speed: Medium-sized blenders typically have a mixing speed of 500-2000 l, which is about 50 rpm. It also has the Froude number less than 1. In contrast, one should consider the recommendation of the supplier.

- Small and minor ingredients should be added to the mixer after the main ingredients (or in a sandwich). It should preferably be in the center of the mixer.

Role Of Ribbon Blender In Different Industries

Ribbon Blender in the Fertilizers Industry

The main advantage of ribbon blenders in the fertilizers industry is their high power and excellent mixing performance. These are better blenders compared to others. The two axes operate in partial motion and help in the large production of natural fertilizers.

Ribbon Blender in the Chemical & Dyestuff Industry

A ribbon blender is great to use in the chemical industries. It is extremely useful for manufacturing granules, dry powder, talcum powder, low viscosity, seasonings, and more.

Ribbon Blender in the Pesticides/Insecticides Industry

For the pesticides/insecticides, the ribbon blender combination is perfect. The tool is immensely useful as the quantities of dry and wet powder are treated by the pesticide industry. It has a horizontal U-shaped tube along with a horizontally mounted shaft.

Ribbon Blender in Mineral Industry

A ribbon blender is perfect to use for dried powders' homogeneous mixing. It is great to mix with varying bulk densities of the mineral industries. Besides, the ribbon blender is an efficient and flexible mixer also for semi-wet materials. One thing to notice is that different Ribbon types are required to serve numerous components.

Ribbon Blender in Pigments Colors Industry

The ribbon blenders are specifically designed to provide a robust mixing capacity. The power that can mix the little quantities into the big stocks. Primarily, it was used for dry products. However, fluid and fuel streams were not included. A wide variety of usable configurations are for batch or continuous blending.

Options Of Ribbon Blender By iPharMachine

As a pharmaceutical equipment supplier, iPharMahcine provides a wide range of dry & wet power mixing machines, which can be used in mixing dry or wet powdery material evenly. They can help you mix powder or granular materials in pharmaceutical, chemical and food industries.

Ribbon Blender WLDH 100L

iPharMachine offers the ribbon blender WLDH 100L that offers one unit motor of 3KW. It has a speed reducer KC-57 and an output rotation of 60 minutes. The production capacity of the equipment ranges between 40-60 kg/ounce.

This ribbon blender has a discharging unit of DN-129. Besides, it offers the intermediate relay, contactor, air switch, and thermoelectric protection. Its mixing tank is 3mm, and the mixing paddle is 6mm. The side plate, motor plate, and stiffener are also 6mm thick.

Ribbon Blender WLDH 200L

The second option by iPharMachine is a ribbon blender of 200L WLDH. It has a ribbon motor of 3KW and a hybrid speed reducer of K-77. The thickness of the mixing tank plate of this equipment is 3mm, and the thickness of the mixing tank cover is about 2mm.

The production capacity of the device is from 80-120 kg/h. The overall dimension of this product is 1800x650x1100. The mixing paddle is 6mm thick with the main shaft bearing 6210 and sealing of PTFE packing.

Ribbon Blender WLDH 500L

The hybrid motor of the iPharMachine ribbon blender with WLDH 500L is 5.5KW. The hybrid speed reducer in the machine is K-87. The thickness of the mixing tank plate is 4mm, and the mixing tank cover is 3mm.

The main shaft bearing of this equipment is 6210, and the sealing of the main shaft is PTFE packing. The whole dimension of the ribbon blender WLDH 500L is 2100x750x1300. Lastly, the production capacity of this tool is 200-300 kg/h.

Some Maintenance Tips For Ribbon Blender

Here are some tips for the maintenance of the ribbon blender:

Maintain the Seal

Seals for the blender and mixer keep materials within while also guarding against shaft movement. Material may leak from a broken seal, and the shaft's alignment may change. It is why it is advised to maintain the mixer advice for each type of seal depending on your machine.

Lubrication

Your mixer's lifespan can be prolonged for many years by routinely monitoring the lubricant levels. Ensure that the moving parts are properly greased. It is among the most crucial general mixer and ribbon blender maintenance advice to remember. Some mixer components, like the drive components, account for a sizable portion of the mixer's cost.

Protect the mixer tub

The mixer's body is an essential component of effective ingredient system mixer maintenance. The machine's body can be harmed if the blender is too close to the walls. Keep in mind that the mixer is made to best suit the needs of your ingredients; if the parts are not properly aligned, the mixture will not be effective.

In The End

Lastly, we want to tell you about the right place where you can get the best ribbon blender. iPharMachine is a trusted company that offers high-quality blender equipment for medicine and other manufacturers. The machines provide efficient performance and help in the bulk production of the products.

You can check the website and see what best suits your requirements. We can assure you of a powerful device that can stand still in different situations.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche