What is a Shrink Wrap Machine: An Updated Guide in 2024

Are you struggling with how to package your products? A shrink wrapper may be the right packaging equipment for you. It allows you to package your products safely and efficiently. Shrink wrapping machines use shrinkable plastic film to tightly seal your products.

So, when choosing a shrink wrap machine, it's important that you know some basic information about it. What is a shrink wrap machine? How does a shrink wrapper work? What are the major types of it?

This guide encapsulates everything you need to know about shrink wrapping machines. Once you've read it, I'm sure you'll be able to make a more informed choice when purchasing your own shrink wrapper.

What is a Shrink Wrapping Machine?

A shrink wrapping machine is a device used for heat shrink packaging. When a product enters the shrink wrapper, the machine will wrap a layer of transparent plastic film around it. The heat generated by the machine then causes the film to shrink, wrapping the product tightly. In this way, a strong, tamper-resistant film is formed on the outside of the product.

What are Different Types of Shrink Wrap Machines?

There are many types of shrink wrap machines on the market, each designed for specific needs and product types. Let's check out some of the most common types of shrink wrapping machines.

I-Bar Shrink Wrap Machine

Image Source: Pro Pack Solutions

The i-bar shrink wrapper is a manually operated packing machine. It has a very simple design, using only an i-bar sealer and an infeed roller to do its job. The i-bar shrink wrapping machine is operator friendly as it can cut and seal the film at the same time with only one action.

In addition, this i-bar shrink sealer is ideal for stock shrink bags. You fill the product into the stock bag and then shrink the bag with a heat gun. So you have perfectly completed sealing a product. However, this kind of manual shrink wrapping machine has an obvious shortcoming. That is, it can only fulfill low volume packaging needs. Because by its nature, it cannot operate at high speeds like an automatic shrink wrapper.

L-Bar Shrink Wrap Machine

L-bar shrink wrappers are the most popular category of shrink wrap machines. In the shrink sealer market, l-bars are usually available in manual, semi-automatic and automatic models.

- Manual L-Bar Shrink Wrap Machine

Manual l-bar shrink wrap machines rely heavily on the operator. Operators play a hands-on role in the packaging process. They manually place a product into the sealing area and then pull down the sealing lever to create a seal on the film around the product. This kind of manual control allows for more precise sealing of products. So, the manual l-bar shrink wrapper is ideal for small-scale production.

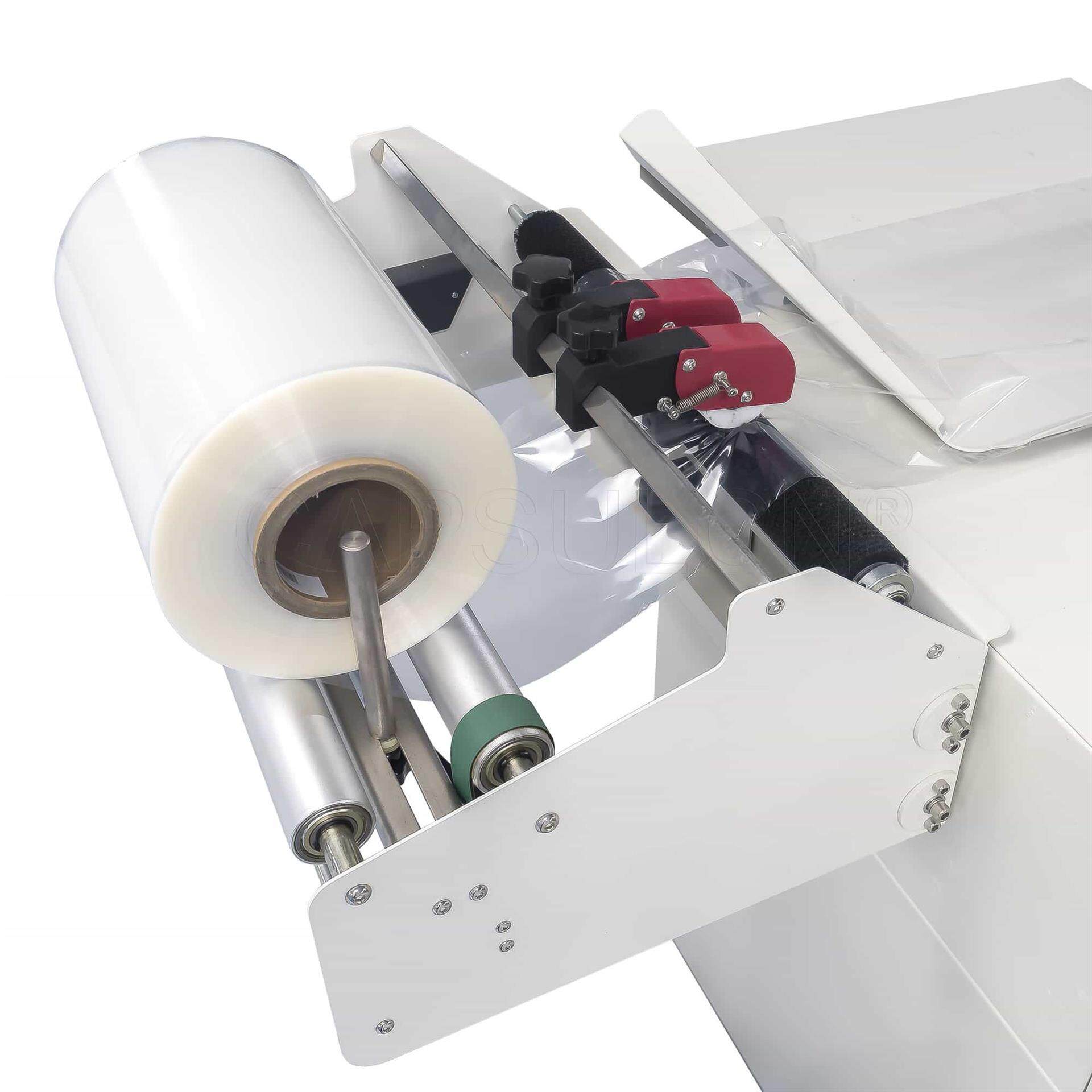

- Semi-Automatic L-Bar Shrink Wrap Machine

The semi-automatic l-bar shrink wrapper combines manual and automatic functions. Although the operator still needs to manually feed the product into the machine. But once the product is in place, the semi-automatic l-bar shrink wrapper uses its sealing bar to automatically cut and seal the film outside the product.

This level of automation ensures consistent and accurate sealing and reduces reliance on operator skill. The sealing bar of the semi-automatic shrink sealer is controlled by a very simple control panel. The operator can adjust parameters such as heating temperature and time from the control panel.

- Automatic L-Bar Shrink Wrap Machine

Compared with the first two types of l-bar shrink wrap machines, automatic shrink wrapper runs faster and can pack more products in the same amount of time.

In addition, automatic shrink wrappers are more versatile, allowing for automatic film feeding, sealing, shrinking, and product discharge. With virtually no manual labor needed, this type of machines provide the fastest speeds and highest efficiencies for high-volume production lines.

Side Seal Shrink Wrap Machine

Image Source: Texwrap

When it comes to side seal shrink wrapping machines, you will be faced with two options: intermittent and continuous. Both types of machines are efficient solutions for packaging your products, but they work in totally different ways.

- Intermittent Side Seal Shrink Wrapper

The intermittent side seal shrink wrapper runs in cycles but with intervals. Once the product is placed on the conveyor, the sealing strip drops and seals the film around the product. After sealing, the film and product will move a set distance before stopping, and the operator places the next product. This cycle is repeated for each product.

Because intermittent side seal shrink wrappers can only handle one product at a time, so they will be slower than the continuous type in terms of speed. This type of wrapping machine is more suitable for small to medium sized projects.

- Continuous Side Seal Shrink Wrapper

The continuous motion side sealer is a wrapping machine that can run continuously. There is no need for downtime between sealing and cutting cycles. The product is placed on a moving conveyor belt and the machine automatically seals the product as it passes over the sealing strip.

In addition, the supply of film is uninterrupted and the operator doesn't have to stop or restart the machine to load the film. This type of machine is capable of high-speed packaging, making it ideal for applications requiring high throughput and efficiency.

|

Features |

Intermittent Motion Side Sealer |

Continuous Motion Side Sealer |

|

Working Principle |

Cycles with intervals |

Continuous motion |

|

Packaging Speed |

Moderate |

Much Faster |

|

Accuracy |

High accuracy |

Sacrificing some accuracy for high speed |

|

Product Handling |

Very flexible |

Less flexible |

|

Cost |

Manual loading and unloading |

Little to no human involvement |

|

Operator Involvement |

Lower cost |

Higher cost |

Heat Gun

In a complete shrink wrapping process, the heat gun is often used as an auxiliary device to the heat shrink sealer. The shrink sealer applies and seals the film to the product, while the heat gun heats and shrinks the film.

Using a heat gun requires skilled manual handling and constant attention. As a result, this equipment is only suitable for small-batch packaging or small-sized products. A heat gun produces concentrated hot air, but its heat distribution is not as even as that of a shrink tunnel. This can lead to uneven film shrinkage and may even damage the product.

Shrink Tunnel

In addition to heat shrink sealers and heat guns, shrink tunnels are also common equipment used in the shrink wrapping process. This type of equipment is designed to meet the needs of large-scale industrial applications. On a product packaging line, you may often see shrink tunnels used in combination with L-bar sealers. This kind of combo maximizes the wrapping efficiency.

Shrink tunnels have a much greater heating capacity than heat guns. In a shrink tunnel, each side of the product is heated evenly. The film wrapping the product shrinks with the heat, and creates a tight, secure seal around the product. A heat gun, while also effective at heating the product, is still a slow, manual device by nature. So, it can't meet the demands of high-volume production like shrink tunnels can.

Want to better understand the differences between shrink tunnels and heat guns? You can check out the table below.

|

Features |

Shrink Tunnel |

Heat Gun |

|

Function |

Shrink film automatically or semi-automatically |

Shrink film manually |

|

Heating Method |

Infrared, convection or steam |

Centralized hot air |

|

Applications |

High-volume, larger products |

Low-volume, smaller products |

|

Size |

Requires some floor space |

Compact and portable |

|

Cost |

More expensive |

Cheaper |

|

Safety |

Enclosed environment ensures safety |

When using it, you need to be careful to avoid burns |

Top Choices for Shrink Wrappers in 2024

If you want to provide the best protection for your products, a shrink wrapping machine is definitely a good choice. Below we've shortlisted 2 of the top 2024 shrink wrapping machines for you, so you can choose the most suitable one depending on your product type and required output.

1. FQL 450A Semi-Automatic Shrink Wrapping Machine

The iPharMachine FQL-450A l-bar shrink wrapper combines sealing, cutting and bagging functions in one machine, using high quality shrink film as the packaging material. If you are not a large producer but want an efficient packaging machine, then this FQL-450A model is the best choice for you.

Features & Benefits

- This model of shrink wrapping machine is simple to handle

- It can operate independently or in conjunction with other packaging equipment

- The sealing and cutting units of the machine are equipped with overload protection

- The machine is very durable and has a long service life

Main Parameters

|

Model |

FQL 450A |

|

Supply Voltage |

AC220-240V/50-60Hz |

|

Power Consumption |

1200W |

|

Sealing & Cutting Time |

0-3sec |

|

Conveying Time |

0-10sec |

|

Max Conveying Weight(kg) |

25 |

|

Conveying Speed |

0-10(m/min) |

|

Thickness of Film(mm) |

0.015-0.08 |

|

Maximum Product Size(mm) |

500×450 |

|

Dimension(mm) |

1450×850×960 |

|

Overall Weight(kg) |

120 |

2. DS H400 Shrink Wrapping Machine

The iPharMachine DS-H400 shrink wrapper is a compact, cost-effective packaging machine. If you are on a budget, why not try the DS-H400?

Features & Benefits

- This is a stable machine with high heating efficiency

- It has low maintenance cost

- It adopts electronic stepless speed regulation and intelligent temperature control system

- Low noise level when the machine is in operation

Main Parameters

|

Model |

DS H400 |

|

Applicable Materials |

PP, POF, PVC, PE |

|

Speed |

0-12(m/min) |

|

Temperature Range |

0~300°C |

|

Max Conveying Weight(kg) |

5 |

|

Power Consumption |

3KW |

|

Supply Voltage |

220V 50HZ/110V 60HZ |

|

Dimension (mm) |

1000x430x580 |

|

Weight |

54kg |

Final Tips for Choosing the Right Shrink Wrapping Machine

By now, you should have a good understanding of shrink wrapping machines. However, you may still be unsure which shrink wrapper is best for your project. Don't worry, at the end of this guide, we will provide you with some tips on how to choose a shrink wrapping machine.

- First, you have to determine the type and size of your product.

- Secondly, your future monthly production volume needs to be taken into consideration.

- Choose the film material for your product.

- Determine your budget and find out the price of your interested shrink wrapping machines.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche