An Overview of Induction Sealing Machine

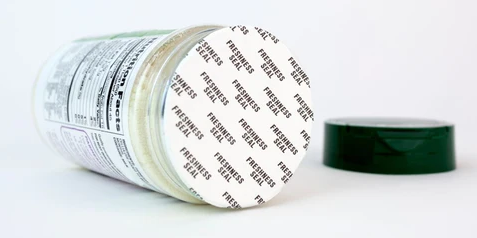

Even though you might not have learned about induction sealing technology before, you certainly have used a product sealed with an induction sealer. Every time you open a brand new bottle of medicine or a can of fresh food, you already break a heat induction seal.

This guide contains everything you might be interested in about induction sealing. What is induction sealing? What are its benefits? What are some popular induction sealers? Take your time, we'll explain it all to you.

What is the Induction Sealing Process?

The induction sealing process is designed to seal containers effectively. This process uses induction heating technology to create a seal that will keep products fresh for a long time.

What Benefits Can Induction Sealing Provide?

When choosing the most appropriate sealing method for your product, you probably want to compare the benefits of each method. Let's take a look at what induction sealing can do for you.

Improve Hygiene in the Sealing Process

Induction sealing is a non-contact sealing technology. When the container passes under the sealing head, there is no direct contact with the sealing head. This is because the force of the foil liner against the bottle opening comes from the cap. This guarantees a hygienic container sealing process.

Tamper Evident

If someone wants to open a container sealed with induction technology, they have to break the package seal. This way consumers know if their product has been tampered with. So, induction sealing helps to give consumers peace of mind about their purchase.

Keep the Product Fresh

Induction sealing technology prevents contaminants from entering the container. Therefore, it can help keep your products fresh and of high quality.

Prevent Leakage

Induction sealing machines can also help you avoid product leakage. If the product is leaked during transportation, it will bring great trouble. But with the induction sealer, you can avoid such accidents.

High Efficiency

Induction sealing machine is a highly efficient bottle packaging device. Compared to other sealing devices, it can seal more containers in a short time. Therefore, if you have the need for mass production, it is a good choice.

Save Costs

Induction sealers typically consume less energy than other sealing equipment. Also, it has low maintenance costs. Induction sealing technology could save money on product recalls since it prevents product leakage.

What is an Induction Sealing Machine?

For a better understanding of induction sealing, it is important to master the machines made based on this technology - induction sealers. Induction sealing machines are designed to meet the need for fast and efficient sealing of containers.

You can find induction sealers in a variety of industries, including the pharmaceutical, food, beverage and chemical industries.

Depending on the user's needs, induction sealing machines are available in a range of sizes and powers.

Major Types of Induction Sealers

If you are considering purchasing an induction sealing machine, you will likely find that there are many types of these machines. Below are two of the most common types.

Manual Induction Sealer

The first type is the manual induction sealing machine. Since it relies heavily on manual operation, it is more suitable for small-scale production. But it does have its own advantages. The manual induction sealer is lightweight and easy to use. Also, it is a cost-effective packaging device.

Automatic Induction Sealing Machine

The automatic induction sealer is an efficient and fast machine. Surprisingly, it can handle hundreds or thousands of containers per minute. Besides, the machine consumes very little energy, minimizing power wastage. It is also a user-friendly machine due to its touch screen control system.

How Does Induction Sealing Work?

By now, you may have read about the definition and advantages of induction sealing. You might be wondering how this technique works as well. In this section, you will find out about the specific steps of induction sealing.

The first step in the induction sealing process is generally to ensure that the cap with the induction liner is correctly placed on the container.

Then, as the container travels on a conveyor belt to the sealing head, the induction sealer generates an electromagnetic current to heat the foil liner in the cap.

As the temperature in the cap rises, several things happen. For starters, the wax in the foil liner slowly melts. When it cools, the polymer layer under the aluminum solidifies and adheres to the container mouth. This is how a durable seal is formed.

Induction Sealing Machines You Might Be Interested In

As an experienced packaging machinery manufacturer, ipharmachine can offer a wide range of induction sealing machines.

To ensure high quality, each ipharmachine machine is rigorously tested before being sold. Whether you are looking for a portable induction sealing machine or an automatic one that can handle high volume production, we have the perfect solution for you.

Below is a collection of the most popular induction sealers from ipharmachine.

DGYF Manual Induction Sealing Machine

The DGFY series is a manual induction sealer line developed by ipharmachine. This machine is lightweight and easy to operate, which makes it ideal for small scale production.

Features

- The handheld design makes the device simple to use.

- Easily move to any position you want.

- It is compact and takes up little space.

- It provides a good seal for containers.

- It can fit a variety of cap sizes without changing the sealing head.

LGYF Continuous Induction Sealing Machine

The LGYF series are continuous induction sealing machines produced by ipharmachine. This series of machines come out of the company's experience and technical improvements over the years. These machines have made a major breakthrough in stability and productivity. So, they have gradually become hot products in various industries.

Features

- The sealing range can be adjusted according to the container size.

- If the machine breaks down, the conveyor belt will stop working automatically.

- The sealing head can lift up and down in two stages, and can seal containers from 20 to 300mm in height.

- The use of air cooling technology greatly reduces maintenance costs and increases productivity.

PBFK Automatic Induction Sealer for Aluminum Foils

PBFK series is a high speed aluminum foil induction sealer line. This efficient machine is capable of sealing various types of containers. It can work independently. Also, it can form a complete production line with other packaging equipment, including tablet counters and capping machines.

Features

- Automation realized by PLC

- Touch-screen control panel for user-friendly operation

- GMP compliant

- It can seal up to 200 containers per minute.

- Solid and durable frame

Are you looking for more details about induction sealing machines? Our team is ready to help you. Contact us today to learn more!

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche