What Is A Tablet Coating Machine: A 101 Guide

Whether you intend to invest in tablet production equipment or simply want to learn about the tablet manufacturing process, tablet coating machines are a crucial part that should never be overlooked.

So, what is a tablet coating machine? If you want to get a rough idea of tablet coating or make an informed decision before purchase, this 101 guide will walk you through all the basics you need to know about the equipment.

First, what is a tablet coating machine?

Tablet coating machines are mechanical devices designed to perform a simple process of applying a thin layer of coating material to the surface of the tablets. They deliver a bunch of benefits by placing a coating solution around the solid oral dosage form.

Why should you use a tablet coating machine?

A tablet is typically formulated with one or more active pharmaceutical ingredients (APIs). The properties of many APIs are highly sensitive to the environment, so they need to be protected by a film of coating against external influences. Here's why you should use tablet coating equipment.

- To mask the unpleasant taste and odor of tablets;

- To make swallowing large dosage forms easier for children and the elderly;

- To provide tablets with an attractive appearance;

- To improve patient compliance;

- To enhance the dosage form's mechanical strength;

- To protect medicines from external environmental factors such as air, moisture, and light while also providing physical and chemical protection for the medication;

- To combine incompatible APIs in a single dosage form;

- To prevent the medicine from dissolving in the acidic environment of the stomach;

- To modify and regulate medication release from tablets by creating products with a delayed-release and sustained-release formulation.

How does a tablet coating machine work?

Though tablet coating machines are classified into multiple types, their principles are more or less similar to one another. If you're curious about how different tablet coater works, we'll talk about that later. So, let's carry on.

Typically, the tablet coating equipment performs a process that includes the following 7 steps:

- Preparation: Batch identification and selection of coating solution recipe;

- Loading: A batch of tablets is loaded into the coating pan by the operator;

- Warming: Preheat the tablets until they reach the set temperature;

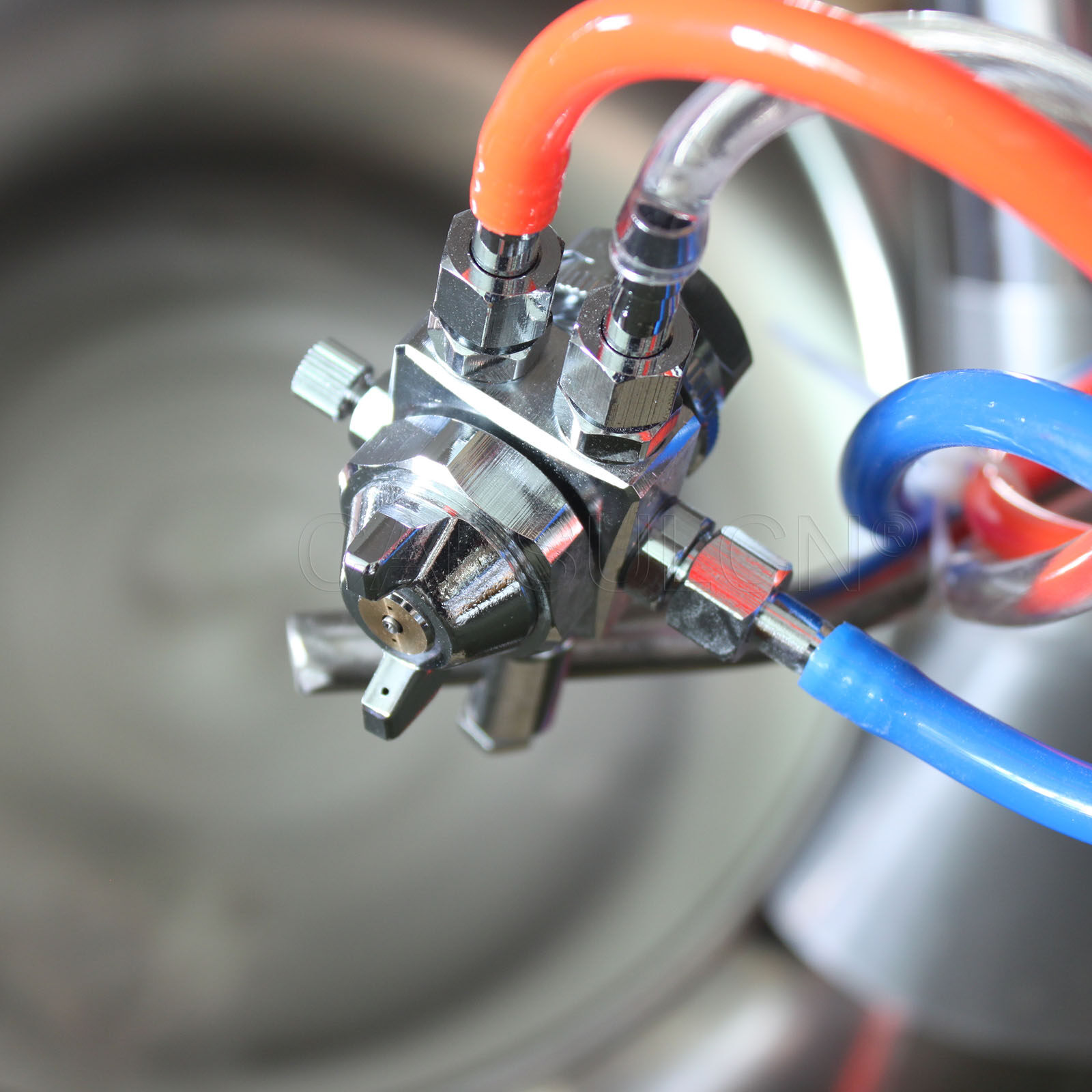

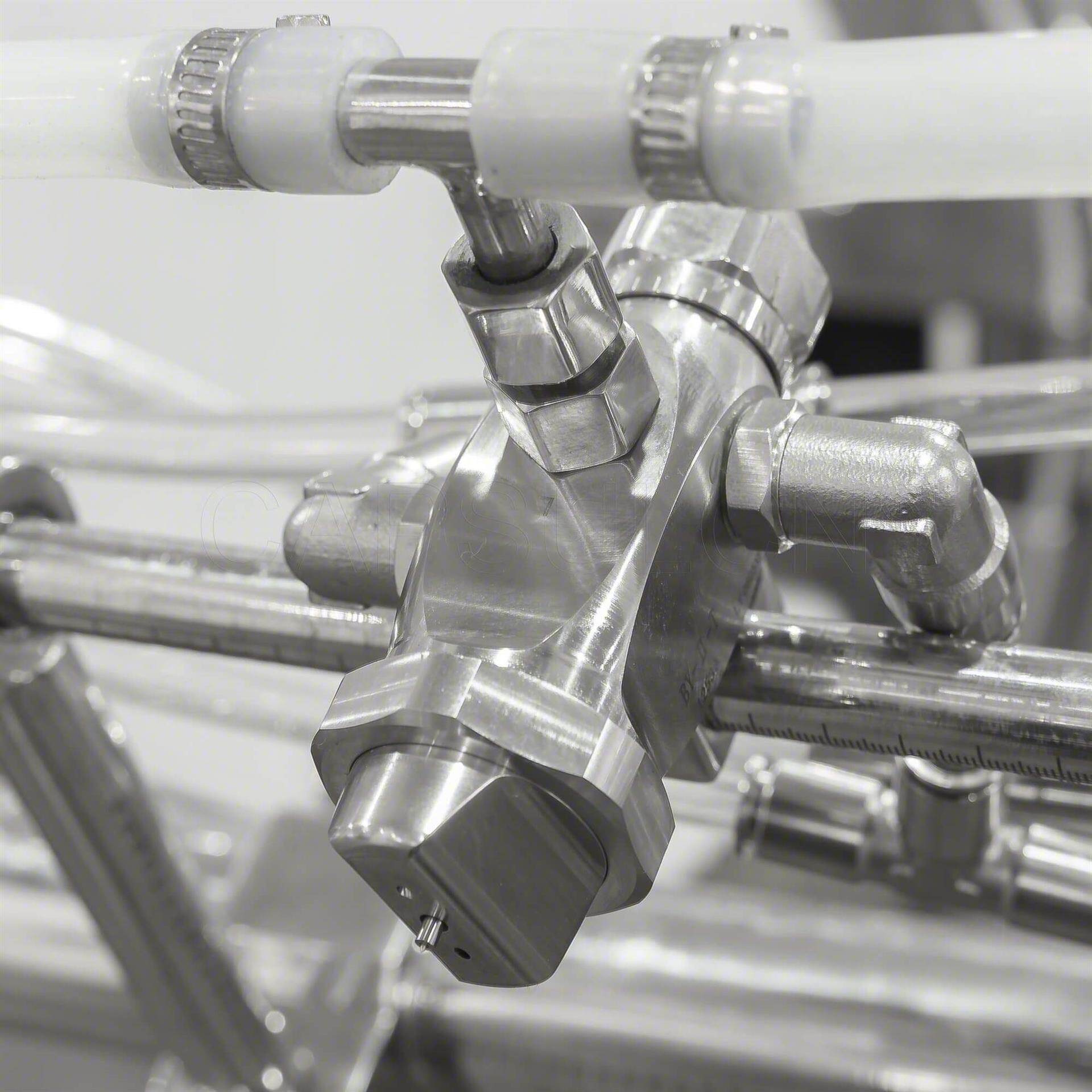

- Spraying: As the tablets rotate continuously in the coating pan, the coating solution is automatically and evenly distributed onto the tablets by an air-atomized spray system;

- Drying: At the same time, heated air is directed into the coating pan under negative pressure. The heated air passes through the tablets so that the coating solution sprayed on the tablet cores will dry fast, producing a solid and smooth film on the surface of the tablets;

- Cooling: The spray guns stop. The pan keeps rotating, enabling the coated tablets to tumble and cool down;

- Discharging: After the batched tablets are completely coated and cooled down, unload them for the downstream process.

Read More:

The 9 Most Important Parts of a Tablet Coating Machine

Common Tablet Coating Defects: Troubleshooting Guide

What are the types of tablet coating machines?

As mentioned above, there are many types of tablet coating machines in the market. They are:

-

Standard coating pan

A standard coating pan comes in a metal pan with a circular opening. The coating pan is mounted at an angle of 30-45 degrees on a stand. The diameter of the coating pan can range from 15 to 200 cm, meeting different production needs.

This conventional coating pan rotates about its horizontal axis, enabling the tablets to tumble inside the pan. Also, it uses an air-atomized spray system to apply the coating solution equally to each and every tablet. At the same time, the heated air is drawn into and leaves the pan through the circular opening to complete the drying process.

Since this tablet coating machine is a conventional type, it has undergone many modifications. There are three types of systems working to enhance drying efficiency.

- Pellegrini pan system

- Immersion sword system

- Immersion tube system

-

Perforated pan or drum

A perforated pan or drum is the most efficient and widely used tablet coating equipment in the industry.

This machine has a drum that is either completely or partly perforated. The drum spins on a horizontal axis in an enclosed housing to coat tablets. Spraying nozzles are used in the perforated pan to uniformly distribute the coating solution to the surface of the rotating tablet bed.

As with the standard coating pan, the perforated pan system also come in a range of variations to improve coating and drying efficiency.

- Accela-cota

- Hi-coater

- Driacoater

- Glatt coater

-

Fluidized bed or air suspension system

Fluidized bed coaters, also known as air suspension systems, are highly efficient machines that employ fluid bed technology for tablet coating.

The equipment uses spray guns to apply the coating material to the tablets. In this system, tablets are suspended in an upward airflow, exposing the maximum area to allow the coating solution and drying air to contact more tablets more quickly.

The top spray, bottom spray, and tangential spray methods are the primary patterns applied to this process.

Benefits of using tablet coating equipment

What is a tablet coating machine? How does it work? I bet the third question hovering in your mind must be: what can you benefit from the equipment?

-

Advantages of standard coating pan

- It can be used for both sugar and film coating processes;

- The air-atomized spray system allows the coating solution to be distributed more quickly and evenly;

- The spray system helps shorten the drying time of sugar coating and allows for continuous film coating;

- The equipment can greatly improve the drying efficiency by employing the Pellegrini pan system, immersion sword system, and immersion tube system.

-

Advantages of perforated pan

- It's applicable for both sugar and film coating processes;

- The most widely used and efficient coating pan system;

- The equipment is well designed to enhance drying efficiency;

- Multiple airflow configurations are available in Glatt coaters.

-

Advantages of fluidized bed or air suspension system

- This system is capable of suspending and coating tablets at the same time to achieve higher production efficiency;

- A high-performance alternative to pan coating;

- It's widely used for coating multiple unit dosage forms;

- The equipment features two spray systems: a high-pressure airless system and a low-pressure air-atomized system, allowing a precise and ultra-fine spray to achieve a perfectly uniform film coating.

Basic requirements of a tablet coating machine

No matter what type of euiqpment you prefer, there are some basic requirements you need to know when selecting automatic tablet coating mamchine manufacturers.

- The equipment should be well designed to easily and evenly distribute the coating solution onto the tablets;

- The equipment should ensure a uniform, smooth, and dust-free surface of the coated tablet;

- The tablet cores have to be more robust than uncoated ones since they have to survive additional processes;

- Use biologically inert material or solvent to coat tablets.

- Each piece of equipment should be GMP or cGMP compliant.

Final words

If you’ve ever had these questions in mind: What is a tablet coating machine? How does it work? What are the benefits of using such a machine? You must have found the answers in this 101 guide.

Tablet coating machines must be efficient enough to catch up with your tablet production. At iPharMachine, we offer a range of tablet coating equipment models of the highest quality for every need. Contact us today to learn more!

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche