Unit Dose Packaging Made Simple: Meaning & 6 Types

Unit dose packaging is now widely used in the pharmaceutical industry. Many medicines, from tablets to liquid drugs, come in this dosage form. Hospitals, pharmacies, and even online drugstores prefer the unique dose of medication. This article helps you know more about this dosage type and keep up with market trends.

- Definition of unit dose package

- Six common types of unit dose packaging

What is a unit dose package?

It refers to medicine that is packaged in an individual pack. Each pack contains a pre-measured amount of medicine, enough for one use. This type of packaging is common in the pharmaceutical industry for tablets, capsules, liquids, and powders. Each is sealed in different types for various purposes.

Unique dose packing is designed for single-use consumption, and easy to use for anywhere. Unit dose packaging has become a standard in the pharmaceutical industry. This packaging ensures that patients receive the correct dose without the need to measure the amount.

Advantages of unit dose packaging

Besides the benefits of easy use, this dosage form also offers many other advantages. The most important one is accurate dosage control. This reduces the risk of over- or under-dosing and maintains proper treatment. For manufacturers, pre-measured doses also prevent waste and ensure consistency in drug administration.

Moreover, with unit dose packaging, patients receive clear instructions and labeled doses. It makes it easier to take the right medicine at the right time. This type is especially useful for individuals who take multiple medications. In addition, many unit dose packages come with child-resistant features, preventing accidental ingestion.

Each dose in unit dose packaging is individually sealed. This protects the medicine from moisture, light, and air exposure. It helps extend the shelf life and maintains the drug’s effectiveness over time. Compared to bulk packaging, unit dose packs keep every medicine sealed and uncontaminated until use. This is especially important for sensitive drugs, such as liquid medications.

Six common types of unit dose packaging

Blister packs

Blister packs are one of the most widely used unit dose packaging formats, mainly for tablets and capsules. They consist of individual blisters that contain medicine. These packs are always made of plastic and sealed with aluminum foil for protection. Each dose remains isolated until used. It ensures freshness and reduces contamination. Blister packs are commonly found in prescription and over-the-counter medications in pharmacies. They are easy to carry, provide clear labeling, and help patients track their doses.

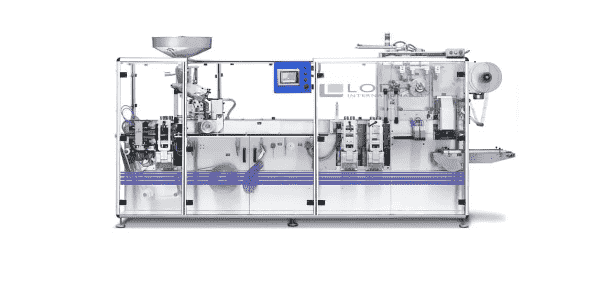

Which machine is used to make blister packs?

Blister packaging machines fill tablets, capsules, and other small medical products into blister packs. These machines create individual compartments by forming plastic or aluminum pockets. They are then sealed with a protective foil or film after filling tablets.

Blister packing machines handle different production speeds and packaging requirements. It greatly improves efficiency and reduces manual labor.

Strip packs

Strip packs are similar to blister packs. But they are sealed between two layers of plastic or foil. It forms a continuous strip to pack each tablet in its own sealed compartment. This protects the medicine from air and moisture.

This type of packaging is often used for bulk distribution in hospitals and pharmacies. In those places, medication is dispensed in large quantities. Strip packs are compact, lightweight, and easy to store. However, once opened, the remaining tablets in the strip may be exposed to air, potentially reducing their shelf life.

Strip packing machines

Manufacturers always use strip packing equipment to make this packing type. They offer high-speed production, precise dosing, and hygienic sealing. So they are ideal for mass production.

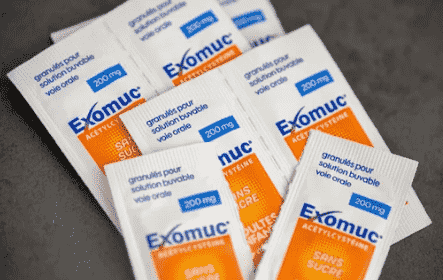

Sachets and stick packs

Sachets and stick packs are small, sealed packets that contain powders, granules, or liquid medications. They are widely used for powdered vitamins, single-dose pain relievers, and liquid medicines like cough syrups. These packs are portable, easy to tear open, and prevent contamination. They are particularly useful for medications that need to be mixed with water before consumption. However, sachets and stick packs require more materials for manufacturing. It may increase packaging waste compared to bulk packaging.

Sachet making machines

If you want to produce sachets, sachet making machines are good choices. They work by forming a sachet from a roll of packaging material, filling it with a precise amount of product, and then sealing it. Depending on the type of product, sachet machines use different filling systems, like powder filling for dry medicines. You can choose the most suitable one based on your production needs.

Ampoules and vials

Ampoules and vials are small containers used for liquid medications, and injections. Ampoules are typically made of glass. They are sealed at the top, requiring breaking before use. Vials, on the other hand, are available in both glass and plastic. They usually contain a rubber stopper. It allows multiple doses to be extracted with a syringe.

These packaging types are essential for vaccines, injectable drugs, and emergency medications. They offer strong protection against contamination and precise dosing. So they are ideal for medical and hospital settings. However, ampoules require careful handling to avoid breakage. And vials can get contaminated if not handled properly.

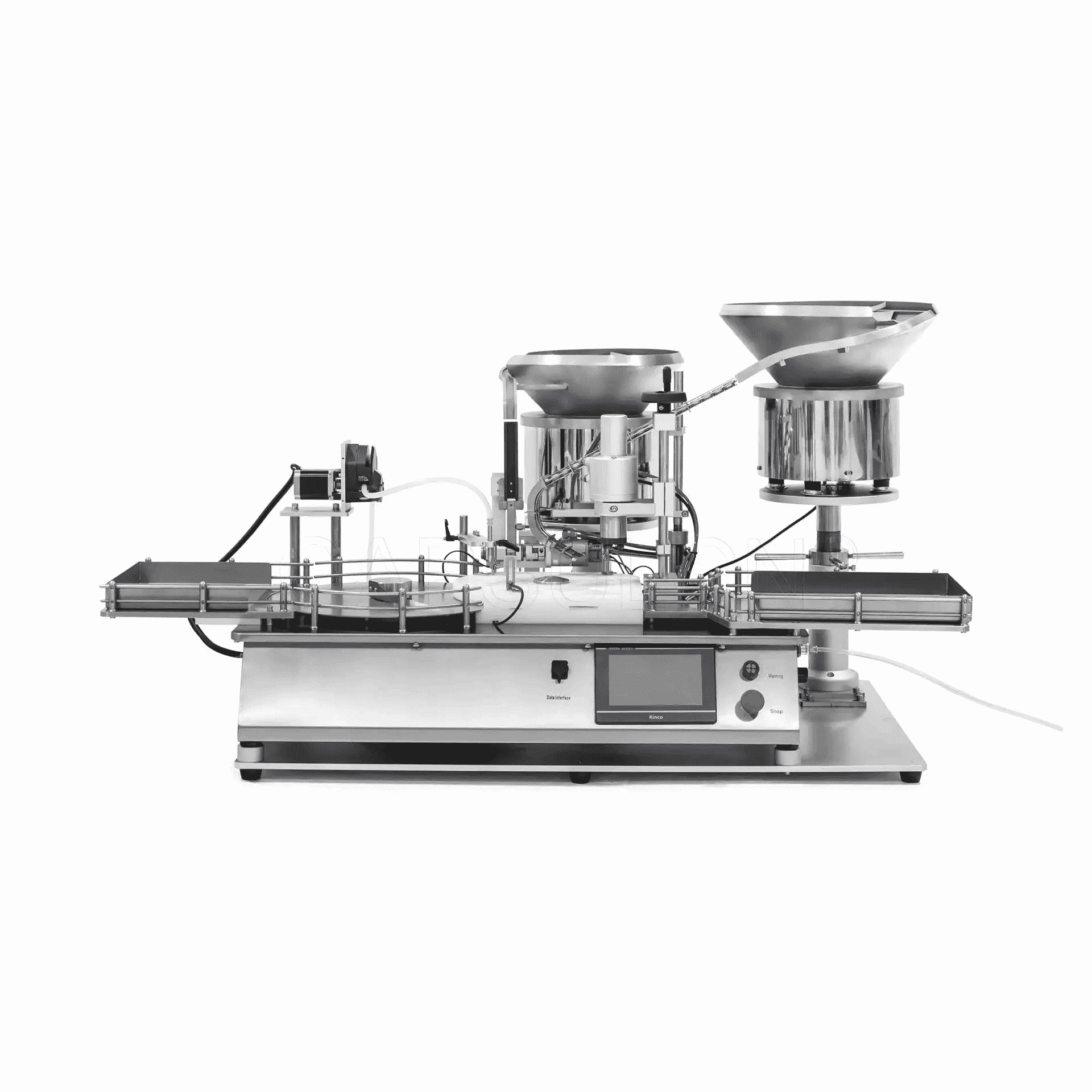

Filling machines to produce vials

Since many injectable drugs require strict hygiene standards, manual filling is not practical for mass production. Vial filling machines are chosen for accurately filling liquid medications into various vials. They are widely used in the pharmaceutical, biotech, and healthcare industries. These machines automate the process. This reduces contamination risks and ensures each vial receives the correct amount of medication.

Pouches and single-use bottles

Pouches and single-use bottles are designed for liquid medications, mouthwashes, topical treatments, and ophthalmic solutions. These packages provide a measured dose and help prevent contamination from repeated use. These forms are especially useful when a patient needs a single-use liquid medication, like in a hospital. Pouches are lightweight and portable, while small bottles provide better protection for light-sensitive liquids. However, single-use bottles and pouches require more budget to produce.

Pouch makers

These machines form pouches from a roll of packaging material, seal the sides, and fill the contents. Finally, they seal the top and get collected. Some models also add labels or print expiration dates directly on the pouch.

Pre-filled syringes

Pre-filled syringes come with a single dose of medication already measured and ready for injection. They are widely used for vaccines, insulin, blood thinners, and emergency medications like epinephrine auto-injectors. The main advantage of pre-filled syringes is that they eliminate the need for manual preparation. It reduces the risk of dosing errors and contamination. They are also convenient in emergency situations in which quick administration is crucial.

However, pre-filled syringes can be more expensive than traditional ampoules or vials. And they require proper disposal after use.

Improve your packing efficiency with iPharMachine

As a leading machine manufacturer in China, iPharMachine has helped 30,000 clients solve various production needs. We offer a wide range of packing equipment, such as blister packing machines, vial filling machines, etc. Whether you run a small or large-scale business, you can find the right machine with the desired automation level. If you have issues after buying, we have a professional team to assist you in troubleshooting.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche