How Does a Vibro Sifter Improve Your Powder Sieving Efficiency?

In many industries, fine powders and granules need precise separation to ensure product quality. So many people use the vibro sifter machines. With its vibrating motion and multiple screen layers, it efficiently sorts materials by size. As key machines in industrial uses, vibro sifters are widely used. Before using it, you need to know

- What is a vibro sifter machine?

- How does a vibro sifter work?

- How to choose suitable vibro sifters for your business?

- What are differences between mechanical sifters and vibro sifters?

- How do strainers and vibro sifters differ?

What is a Vibro Sifter Machine?

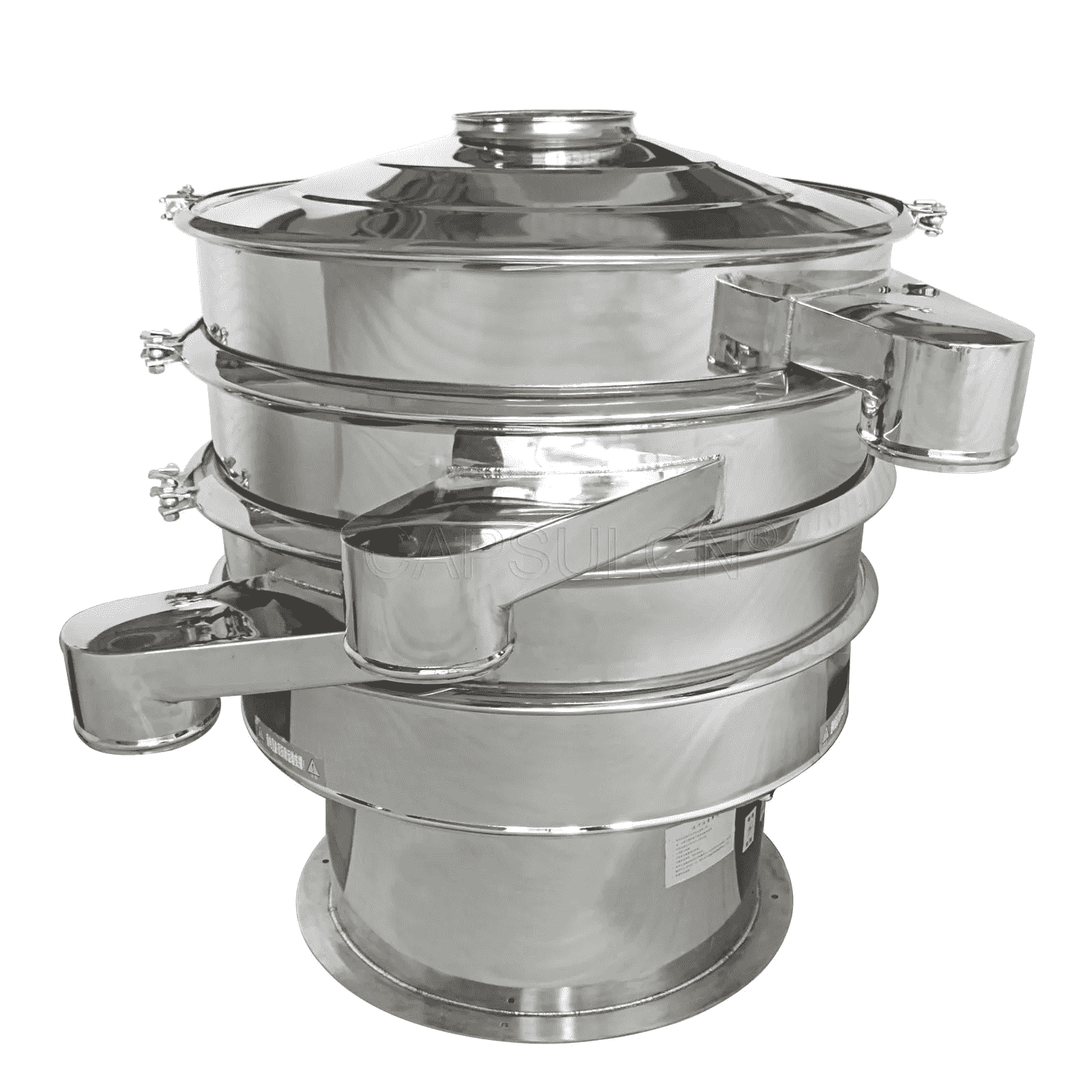

A vibro sifter is a screening machine. It separates particles based on size with vibration. It consists of a motor that generates vibrations. This helps move materials across mesh screens. As the particles pass through different screen layers, they are separated according to their size. The final materials then get uniformity and quality. Besides separation, vibratory sifters can also be used for the scalping and grading process.

What is a Vibro Sifter Used for?

Vibro sifters are used in many industries to separate, filter, and classify powders and granules. They help ensure that materials meet size requirements and remove unwanted particles. Here are some common uses of these machines.

- Pharma industry. It removes oversized or undersized particles to ensure uniformity. Also, it helps in filtering excipients and active ingredients.

- Food and beverage industry. It is mainly used to screen flour, sugar, and other food powders to remove lumps and impurities. It also filters liquids like juices and syrups to remove solid particles.

- Chemical industry. The machine is always used to separate different grades of chemical powders and remove impurities from raw materials.

How Does a Vibro Sifter Work with Different Parts?

A vibro sifter uses vibrations to separate and classify materials. It has a circular screen and a motor with an eccentric weight that creates multi-directional vibrations. These vibrations move the material across the screen. This allows smaller particles to pass through while larger ones stay on top. You can check the see how it works.

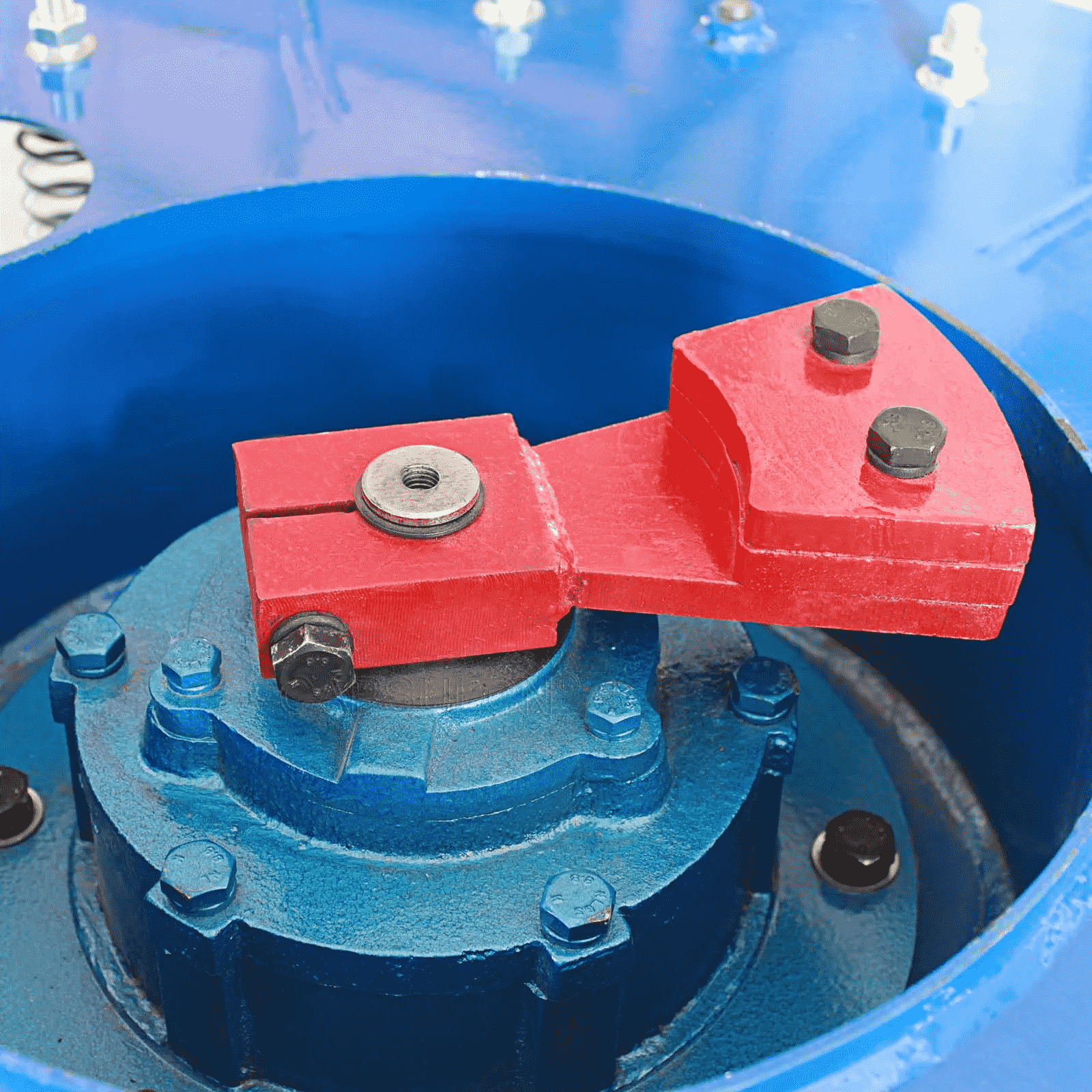

Vibratory Motor

At the center of the vibro sifter is a special vibratory motor. This motor has eccentric weights attached to both the top and bottom of the motor shaft. When the motor runs, these weights create strong vibrations in different directions. These vibrations help the material spread evenly across the screen, improving the sieving process.

Multi-plane Vibrations for Effective Screening

The eccentric weights could be at different positions. They generate circular, horizontal, and vertical vibrations. This multi-plane movement ensures that the material can move in a controlled way across the screen. This increases the efficiency of separation and prevents clogging.

Screening Process and Material Separation

The raw material enters the vibro sifter through the feeding hopper. The vibrations push the material across the screen. Then particles of different sizes are separated. Fine particles pass through the mesh, while larger ones stay on top. If multiple screen layers are used, the material is separated into different grades in a single process.

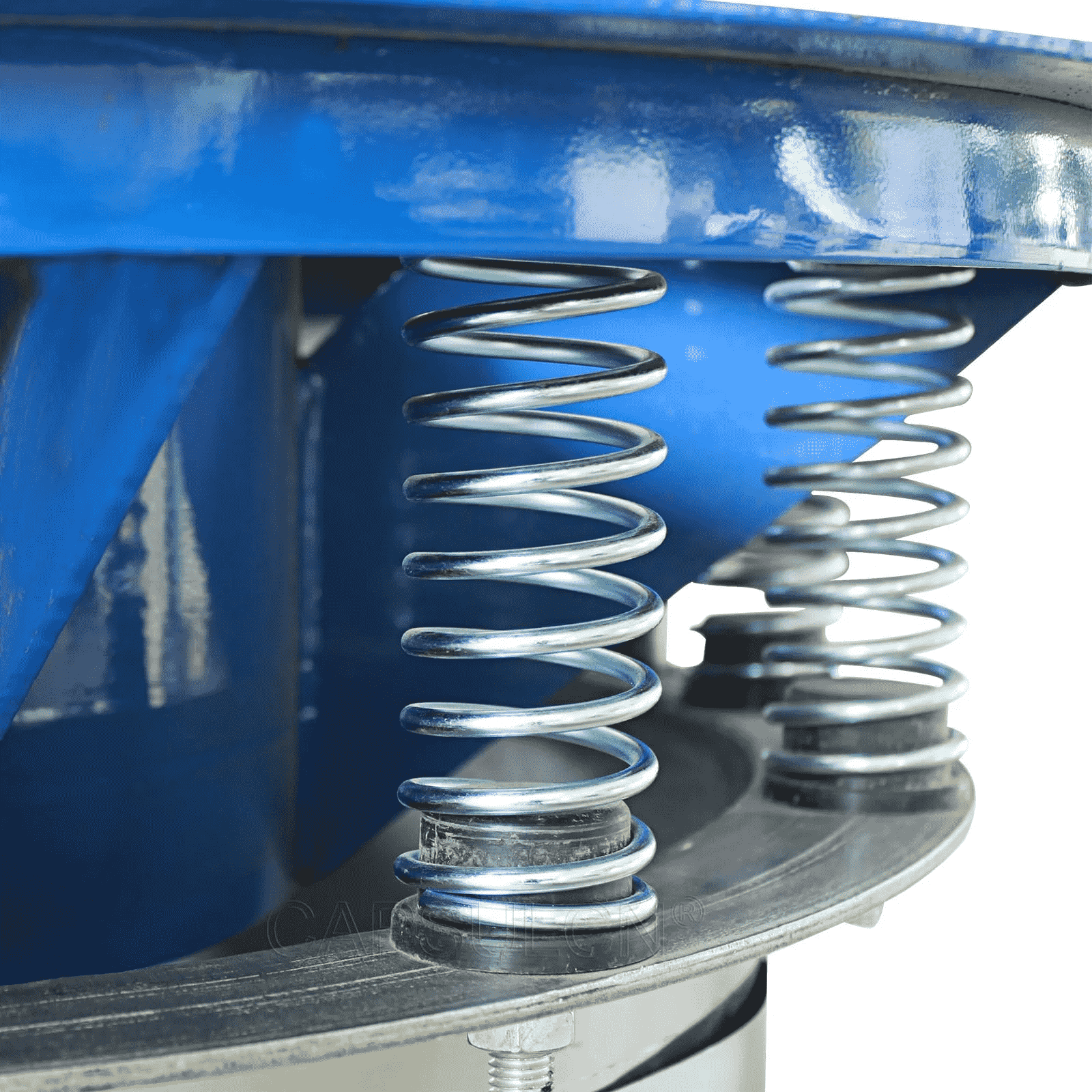

Stable Operation with Springs and Circular Base

There are springs to support the motor. They allow the machine to vibrate freely while keeping it stable. They also help absorb excess vibration. This reduces noise and prevents damage to the machine.

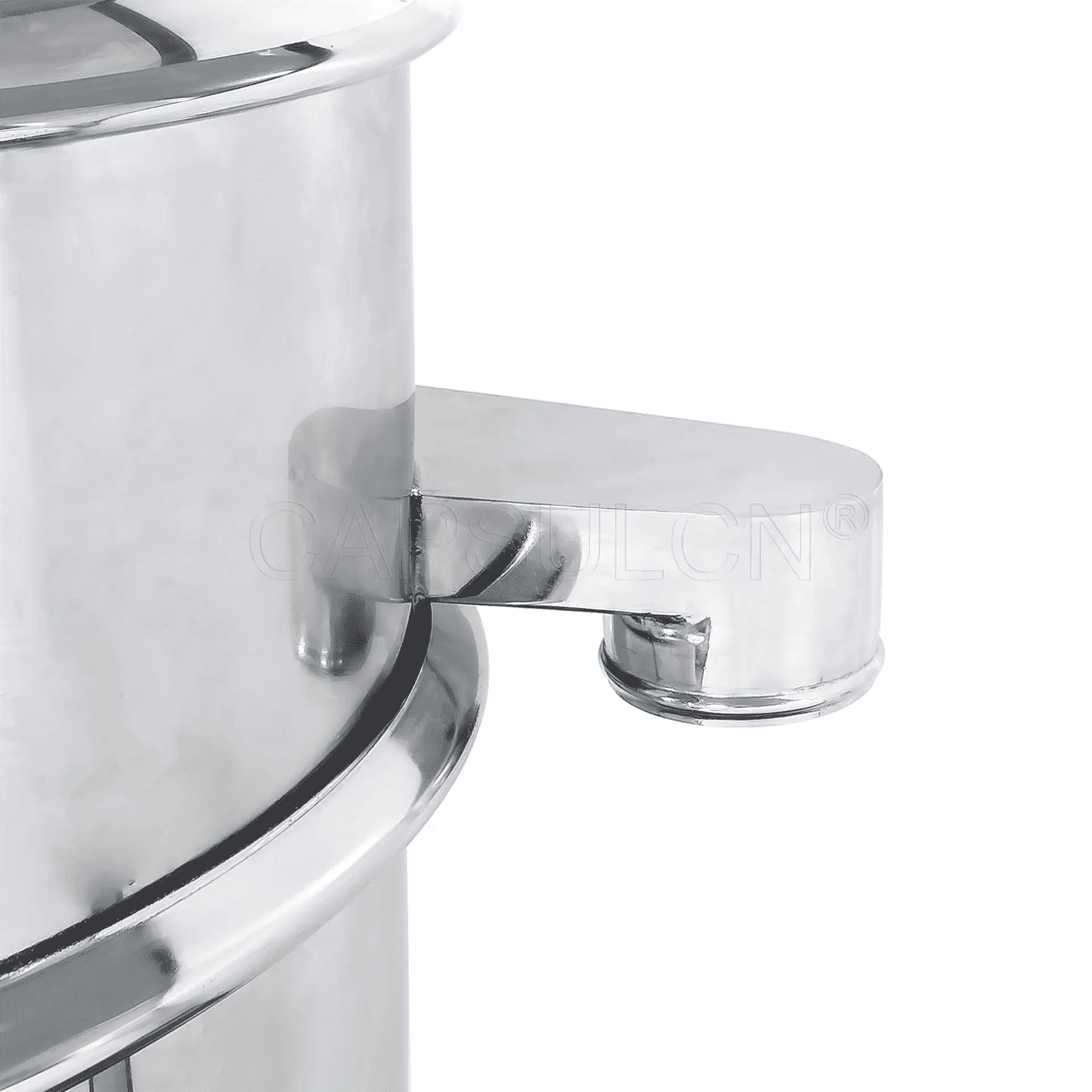

Collection of Separated Materials

Once the material is separated, the fine particles exit through one outlet. On the other hand, oversized or unwanted particles are removed through another. This ensures that only properly sized materials move forward in production.

How to Choose Suitable Vibro Sifters?

Different factors affect the performance and suitability of a vibro sifter for different applications. Here are the key considerations.

Mesh Size

The mesh size determines the size of particles that can pass through the screen. It is measured in microns or mesh count, with higher numbers indicating finer screens. The right mesh size is essential to achieve the desired separation. If the mesh is too fine, it may slow down processing and cause clogging. If it is too coarse, unwanted particles may pass through. So many manufacturers choose to customize the size to meet clients’ needs.

Material Compatibility

The materials used in the vibro sifter should match the type of product. For example, sifters are always made of stainless steel in the pharmaceutical and food industries. Because it is non-reactive, corrosion-resistant, and easy to clean. In addition, some materials may require specialized coatings or food-grade finishes to prevent contamination. In chemical industries, compatibility with acidic or abrasive substances is important. This helps maintain product quality and extends the lifespan of the machine.

Number of Sieving Layers

Vibro sifters can have single or multiple sieving layers. It depends on the need for particle classification. A single-layer sifter separates materials into two fractions: acceptable and rejected particles. Multi-layer sifters allow for grading into different size categories in one operation. For example, a three-layer sifter can classify materials into four different sizes. The number of layers should be chosen based on the level of separation required in the production process.

What is the Difference Between a Mechanical Sifter and a Vibro Sifter?

Mechanical sifters are still used in some industries, but they are not as common as vibro sifters. They are mainly used in applications that require fine particle separation. But there are some people that always mix these two machines. Here are their key differences for your reference.

Working Principle

These two sifters both use motors for processing. But for mechanical sifter, the motor drives a mechanism, like gears, that creates a shaking, rotating, or back-and-forth motion. The movement is often more mechanical and linear, rather than vibratory. This method is effective for basic separation but may not be as precise for fine materials. So these machines are always used in industries like construction and agriculture.

Vibro sifter uses a vibratory motor with eccentric weights to generate high-frequency vibrations. These vibrations move materials across the screen in multiple directions for efficient separation. These vibrations improve the flow of material across the screen, making it more efficient for fine particle separation.

Efficiency and Speed

Mechanical sifters feature slower and less efficient for fine particle separation. It may require multiple passes to achieve the desired result. Vibro sifters are more efficient and faster due to multi-directional vibrations. This improves material flow and prevents clogging. But this equipment may generate more noise depending on the model.

How Do Strainers and Vibrod Sifters Differ?

Both strainers and sifters are used to separate particles, but they serve different purposes and work in different ways. Strainers are primarily used to separate solids from liquids or remove larger particles from a mixture. They work with liquid-based mixtures and some semi-solid materials. For example, they can filter tea leaves or coffee grounds. Their mesh or perforated surface allows liquid to pass through while retaining solid particles. It is commonly used in cooking, filtration, and liquid processing.

Vibro sifters are used to separate dry particles based on size. The process may involve shaking, vibration, or rotation to move materials across the screen. They ensure uniformity in powders or granules. They are mainly used for dry powders, granules, and fine particles.

The End

There are many types of vibro sifters in the market. You need to have comprehensive consideration to select a suitable one. You can also directly contact iPharMachine. We offer various types of vibro sifters to suit your needs. We also have a professional technical team to help you set up the machine and train staff.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche