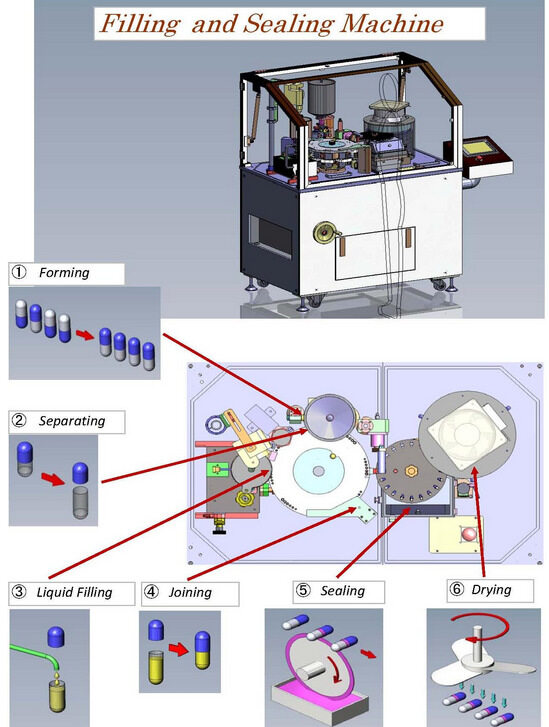

Working Process of Liquid Capsule Filling Machine

The automatic liquid capsule filling machine can complete the filling process of liquid and the sealing of the hard capsule. This device keeps the liquid drug in a sealed state during packaging, storage, transportation, and application, thereby improving product reliability. At the same time, it also meets the high requirements of the pharmaceutical companies for liquid filling and sealing, quality assurance and anti-counterfeiting of hard capsule preparations.

Work Process:

1. Forming. After the hard capsule material is cut from the hopper, and then the caps are arranged in the same direction.

2. Separating. After the capsule is vacuum positioned, the cap is automatically separated.

3. Liquid Filling. Add liquid medication after the fiber is automatically detected and judged.

4. Joining. The capsule body and cap are combined and sealed.

5. Sealing. The finished product discharge is delivered to the sealing machine in an orderly manner through special guide chutes, arranged in the same direction on the conveying mechanism. After the capsule cap body is passed through the gluing mechanism, the rubber wheel is automatically coated with anti-overflow glue.

6. Drying. The anti-overflow glue is naturally dried and solidified by the conveying mechanism during the round-trip conveying process. Thus the product achieves the sealing effect of the hard capsule cap body after rapid drying.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche