Also bought

Introduction

Powder Grinder also name Powder Mill Machine, it is used for milling all kinds of dry materials like herb, Chinese herbal medicine, spices, grains, beans, peanuts, pearls and even the stone. It can also be used for medicine research, cosmetics, internal medicine, surgery, ophthalmology and dermatology medicine.

Adopts top grade motor, mental fan blades, high rotating speed and high power makes the working life longer, can continue working for half an hour. The machine can be used continuously. It is equipped with air-cooling equipment and won't be limited by time. The special structure rotates without vibration, low noise. It costs little wastage and works high efficiently and easily. It is convenient to move and safe to use.

Driven by a motor, the pulverizing steels of the machine rotate at a high speed, and the mechanical energy causes high impact force, compression force and friction on the pulverized material. Therefore, the machine is suitable for fibrous materials, soft materials, and lightweight materials.

- Safety and health - aluminum alloy shell increases the heat transfer coefficient; all the part of the pulverizing chamber is made of stainless steel, more sanitary. A safety switch is equipped to ensure the safety of the operation.

- Low in noise - vertical motor, low noise. (about 45 decibels)

- Uniformity of fineness - lateral discharge port, more uniform fineness of the finished product. The twill pulverizing grooved plate enhances the friction coefficient to quickly get finished products with uniform fineness.

- Good dust removal effect - with the air inlet damper, remove dust and heat by adjusting the introduced airflow, no extra dust removal equipment needed. The special dust bag is helpful in loss reducing and heat transfer.

- High utilization rate - the blade is made of alloy steel, hammer crushing, so it can be used for fine pulverizing and pulverize special materials.

- Pulverizing blade set replacement- it is convenient to replace the pulverizing blade set and the twill pulverizing grooved plate.

- Customizable filter screen - customization is available for the filter screen of 0.2mm-2.0mm.

Specifications

| Model | YF3-1 |

|---|---|

| Capacity | Continuous |

| Output | 2-20kg/h |

| Voltage | 220V 50HZ/110V 60HZ |

| Power | 2200W |

| Rotational Speed | 2800r/min |

| Fineness | 0.5-1.0mm |

| Weight(kg) | 25kg |

| Dimension(mm) | 550x170x530mm |

Reverse side of the machine

Obeverse side of the machine

Pulverizing chambe

| 1. Feeding hopper | 2. Feeding adjusting screw | 3. Expanding air inlet |

|---|---|---|

| 4. Upper cover | 5. Butterfly nut | 6. Interface of dust collecting bag |

| 7. Interface of collecting bag | 8. Machine Body | 9. Base |

| 10. Safety switch | 11. Power switch | 12. Overload protector |

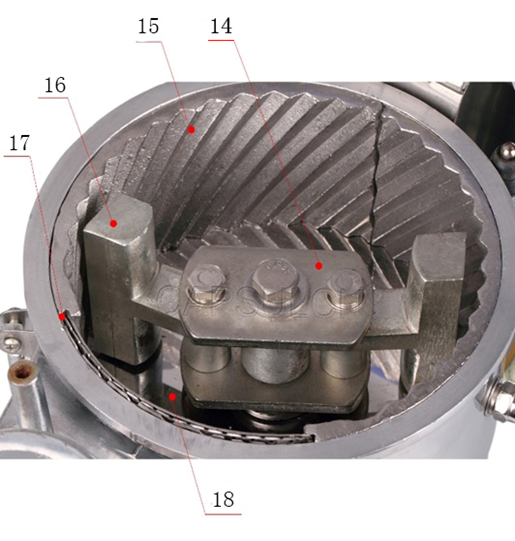

| 13. Ampere meter | 14. Pulverizing blade set | 15. Twill pulverzing grooved plate |

| 16. Sledgehammer | 17. Guide plate of filter unit | 18. Pulverizing chamber |

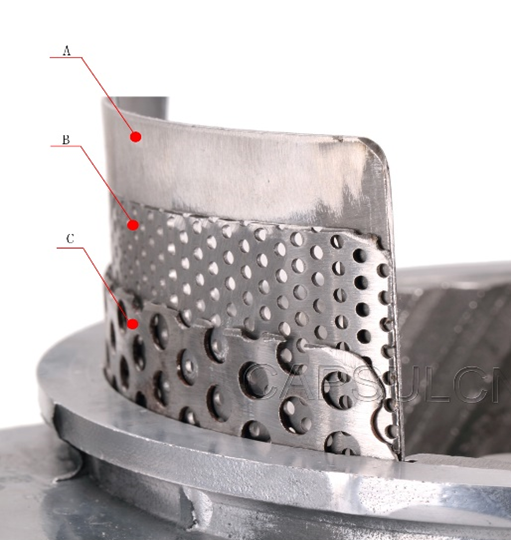

| A. Pane | B. Screen | C. Backstop |

|---|

review(s)

good stuff

The grinding speed is very fast and very small, very good

From: sevide | Date: 3/1/2021 1:40 AM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche