Introduction

ZKS Series of Pneumatic Vacuum Conveyors offers safe and hygienic powder handling. They are used throughout the pharmaceutical food and chemical industries for the transfer of powder, dust, granulated material, and small components. Even small metal chips from milling can be aspirated and conveyed without causing wear to the conveyor.

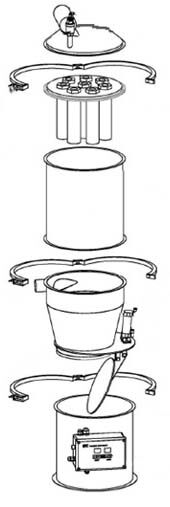

The Vacuum Conveyor consists of vacuum pump(no oil and water), stainless steel suction tube, flexible hose, PE filter or SUS 316 filter, compressed air cleaning device, pneumatic discharging device, vacuum hopper, and automatic level control device.

The vacuum feeder is divided into two types: gap discharge and continuous discharge. The gap discharge helps to reduce the investment cost of the equipment and facilitates the material level control. In most cases, we recommend that the user use the gap discharge type. Continuous discharge is generally used for vacuum conveying of materials over long distances and large production volumes.

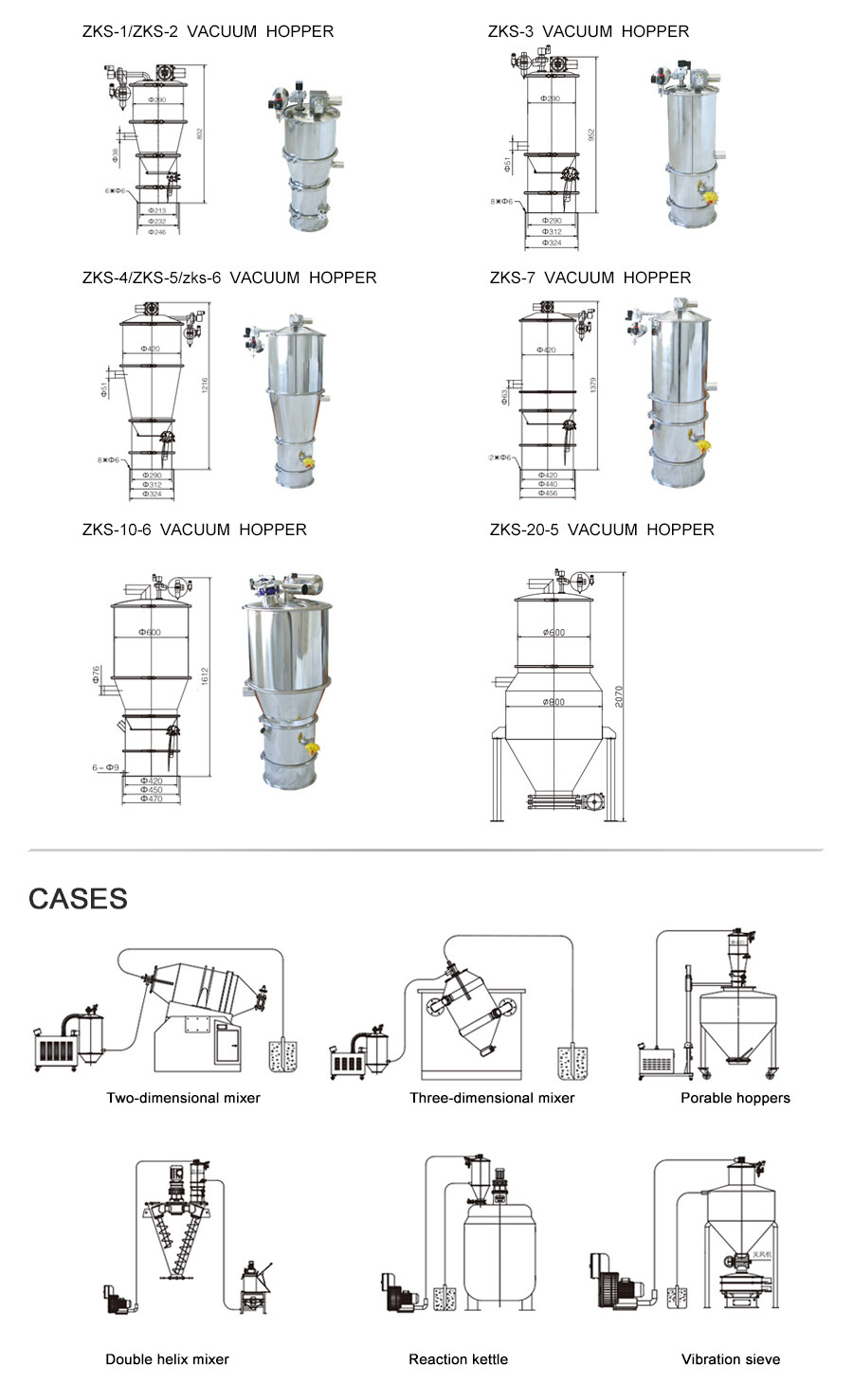

Specifications

| Model | Capacity | Power | Compressed Air | Air Pressure | Size(mm) |

|---|---|---|---|---|---|

| ZKS-1 | 400L/h | 1.5kw | 8L/min | 0.5-0.6Mpa | Φ290*802 |

| ZKS-2 | 600L/h | 2.2kw | 8L/min | 0.5-0.6Mpa | Φ290*802 |

| ZKS-3 | 1200L/h | 3kw | 10L/min | 0.5-0.6Mpa | Φ290*952 |

| ZKS-4 | 2000L/h | 5.5kw | 12L/min | 0.5-0.6Mpa | Φ420*1216 |

| ZKS-5 | 3000L/h | 4kw | 12L/min | 0.5-0.6Mpa | Φ420*1216 |

| ZKS-6 | 4000L/h | 5.5kw | 12L/min | 0.5-0.6Mpa | Φ420*1216 |

| ZKS-7 | 6000L/h | 7.5kw | 17L/min | 0.5-0.6Mpa | Φ420*1379 |

| ZKS-10-6 | 6000L/h(Conveying distance 10m) | 7.5kw | 34L/min | 0.5-0.6Mpa | Φ600*1612 |

| ZKS-20-5 | 5000L/h (Conveying distance 20m) | 11kw | 68L/min | 0.5-0.6Mpa | Φ800*2070 |

Note: The conveying capacity is measured when the conveying tube is 4 meters long and the conveying material is flour. The longer the conveying tube, the lower the conveying capacity will be. Conveying capacity also has a significant relationship with the properties of the materials.

Remarks

- Vacuum Conveying: Safe, Easy, And Efficient

- HYGIENE: Avoid dust dispersion and product contamination. The conveyed material is kept in an isolated environment from pick up to the release point.

- PRODUCT QUALITY: Move pharmaceutical mixtures while still preserving their integrity and keeping the percentages of single components intact.

- PRODUCTIVITY: Increase the automation and health and safety of your personnel by eliminating the task of manually scooping powder into process machines. Conveying can reduce staffing requirements and load times by more than 50%.

Structure

Working Principle

When the air pump rotates, the negative pressure of the air pump forms a vacuum airflow, and the material is sucked into the suction port to form a gas flow, which passes through the suction pipe and reaches the silo of the loading machine. The filter completely separates the material from the air. When the material is filled in the silo, the controller automatically cuts off the power, the vacuum feeder stops working, and the silo door automatically opens, and the material falls into the hopper of the equipment. At the same time, the compressed air automatically cleans the filter through a pulse backflush valve. The feeder is automatically started when the time is up or the level sensor sends a loading signal. The utility model has the advantages of simple structure, small volume, no maintenance, low noise, convenient control, elimination of static electricity of materials and compliance with requirements. The high vacuum generated by the vacuum air pump, the air pump vacuum powder feeder uses the high pressure of the air pump to realize the transportation of the material. The material to be conveyed is prevented from stratification, and the uniformity of the composition of the mixture is ensured. It is the first choice for mechanical automatic feeding of non-woven machinery, tablet press, capsule filling machine, dry granulator, packaging machine, pulverizer and vibrating screen.

Factors affecting the accuracy of vacuum feeder

Positioning methods

Different positioning methods have different influencing factors. When the mechanical stop is positioned, the positioning accuracy is related to the stiffness of the block and the speed at which the block is abutted.

Positioning speed

The positioning speed has a great influence on the positioning accuracy. This is because the energy of the moving parts that must be dissipated differs when the positioning speed is different. Generally, in order to reduce the positioning error, the positioning speed should be reasonably controlled, such as improving the cushioning performance and the buffering efficiency of the buffer device, and controlling the driving system to slow down the moving parts in time.

Equipment accuracy

The manufacturing precision of the manipulator and the accuracy of the installation speed control have a direct impact on the positioning accuracy.

Weight of moving parts

The weight of the moving part includes the weight of the robot itself and the weight of the object to be grasped. The change in the weight of the moving parts has a great influence on the positioning accuracy. Generally, when the weight of the moving member is increased, the positioning accuracy is lowered. Therefore, it is not only necessary to reduce the weight of the moving parts themselves, but also to consider the influence of the change in the weight during work.

Position control accuracy

The position control accuracy of the control system switch control, electro-hydraulic proportional control and servo control is different. This is not only due to the different accuracy and sensitivity of the various control elements, but also to the presence or absence of position feedback devices.

review(s)

Best

The vacuum delivery is very good, and the capsules are safe and sound.

From: Chius | Date: 3/3/2021 9:33 PM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche