Video

Introduction

The box-conveying mechanism guides the box to the optical fiber, after which the box-loading cylinder pushes it into the box storage rack. When the set quantity is reached, the box-pushing cylinder pushes these boxes into the heat-seal mechanism for heat sealing, cutting and cooling.

The conveyor belt carries the boxes (it can be connected with a cartoning machine); adjust the blocking strip and the optical fiber sensor according to the number of boxes; the box-loading cylinder moves back after feeding boxes; when the target quantity is reached, the box-pushing cylinder pushes the boxes into the heat-seal position; the box-pressing cylinder presses the boxes; the box-pushing cylinder moves back; the upper cutter servo starts to work; the film-pressing cylinder starts to work; the upper cutter servo is in place; the lower cutter cylinder starts film sealing; the upper cutter servo still keeps its place; the lower cutter cylinder moves back; air blows for cooling; the upper cutter servo moves back; and the baling process is finished!

Feature

- Machine for packing boxed products in food and pharmaceutical industries

- Uses PE film

- Can pack boxes ranging from 506090mm to 240150300mm

- Packing speed ranges from 8-15 bales per minute

- Equipped with imported electronic components, PLC control system, and HMI

- Conveyor motor power is 120W with synchronous belt transmission

- Box-loading mechanism uses built-in optical fiber

- PLC sends signal to box-pushing cylinder once target quantity is reached

- Heat-seal mechanism includes upper and lower heat sealing

- Overall dimension of the machine is 11008001600mm, with a total weight of 350kg

Specifications

| Model | CKB-180K |

|---|---|

| The maximum packing size | 240*150*300mm |

| The minimum packing size | 50*60*90mm |

| Packing material | PE film |

| Applicable packing tape(width) | 30-80mm |

| Packing film thickness | 30-80μm |

| Packing speed | 8-15 bales per minute(depending on the size and layers of the box) |

| Power supply | 220V/50Hz |

| Power | 800W |

| Working pressure | 0.6-0.8MPa |

| Overall dimension | 1100*800*1600mm |

| Conveying size | 1300*250*800mm |

| Total weight | 350kg |

Remarks

-

Just after the machine finishes working, do not touch the heat-seal cutter and its surroundings, because it takes a certain time for the heat-seal cutter to cool down.

-

Place the machine on a flat ground and keep the surroundings clean and tidy.

-

If you are not sure how to operate and maintain the machine, please contact us and we will solve your problems in the shortest time.

-

Before repair, confirm that all power supplies have been switched off to be disconnected.

-

Repair the machine with right tools and replacement parts.

-

Only well-trained persons can repair the machine according to the relevant instructions.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

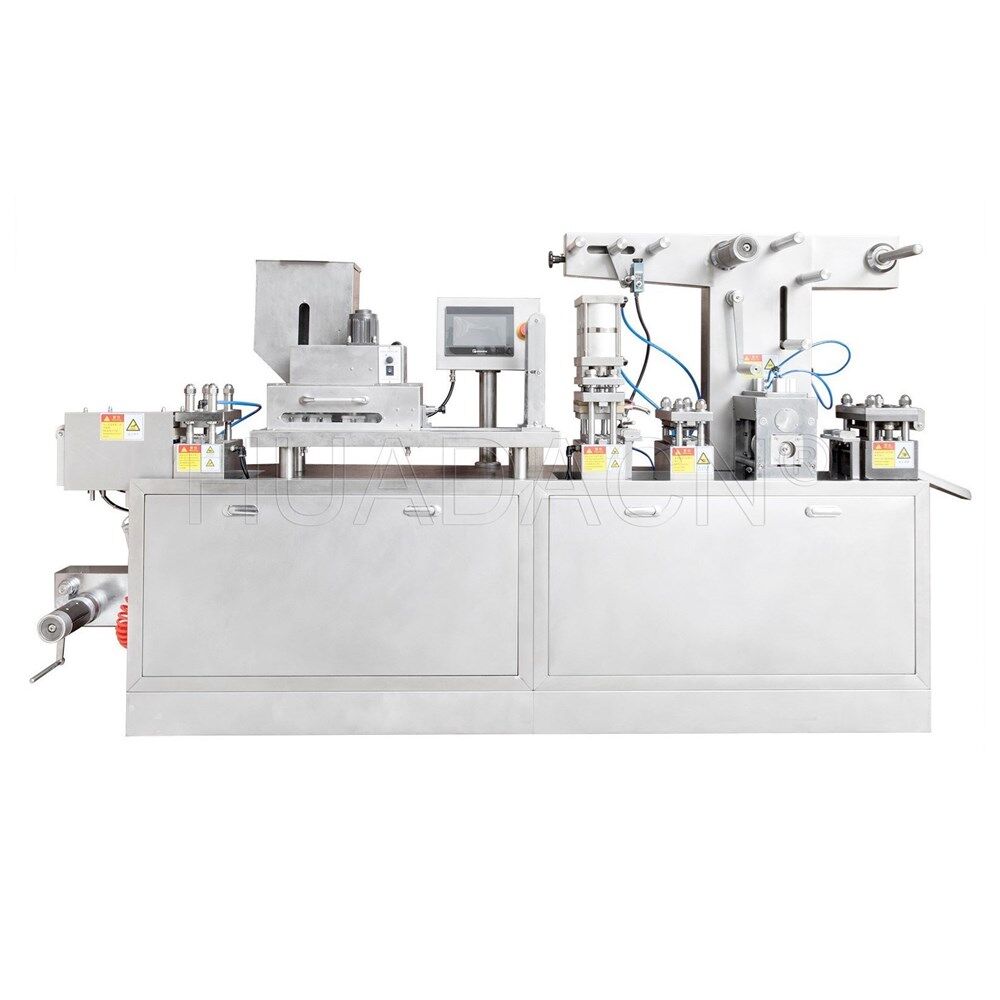

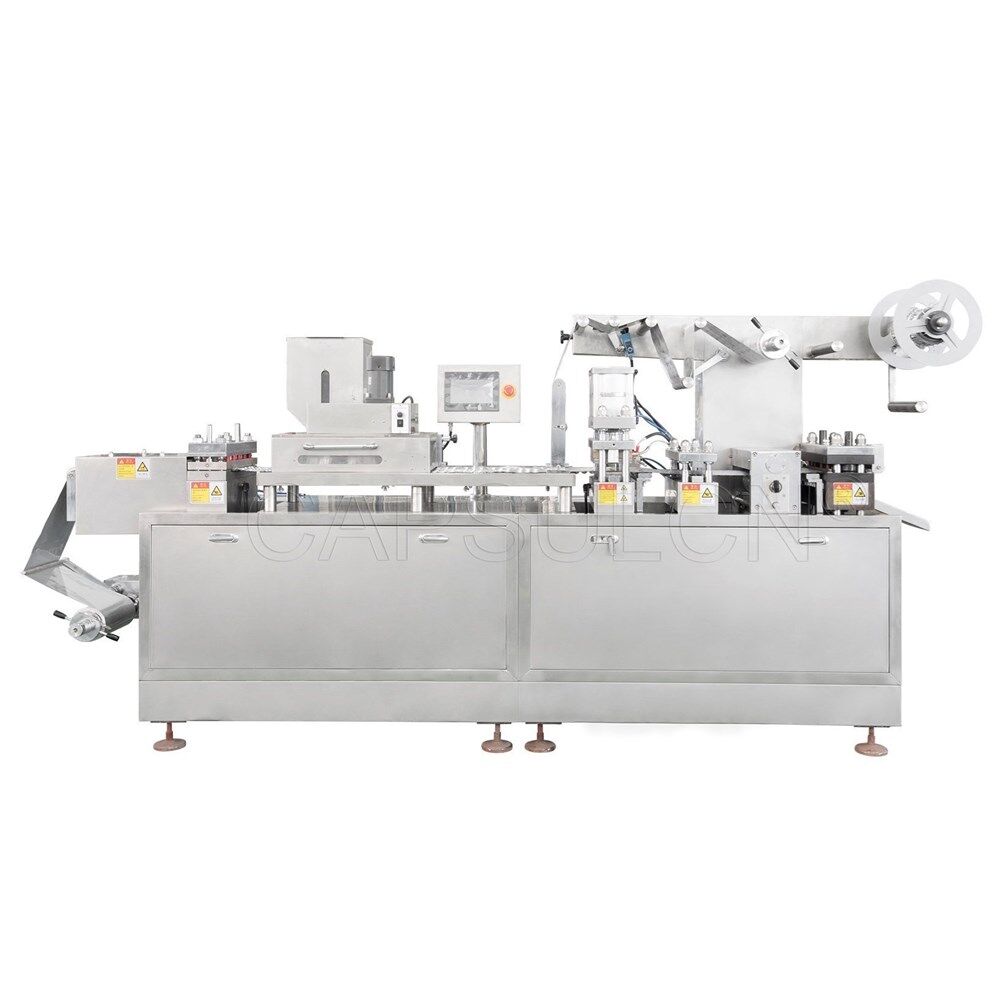

Blister Packing Machine BM-Ⅳ

Blister Packing Machine DPP-160

Blister Packing Machine DPP-250

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche