Video

Introduction

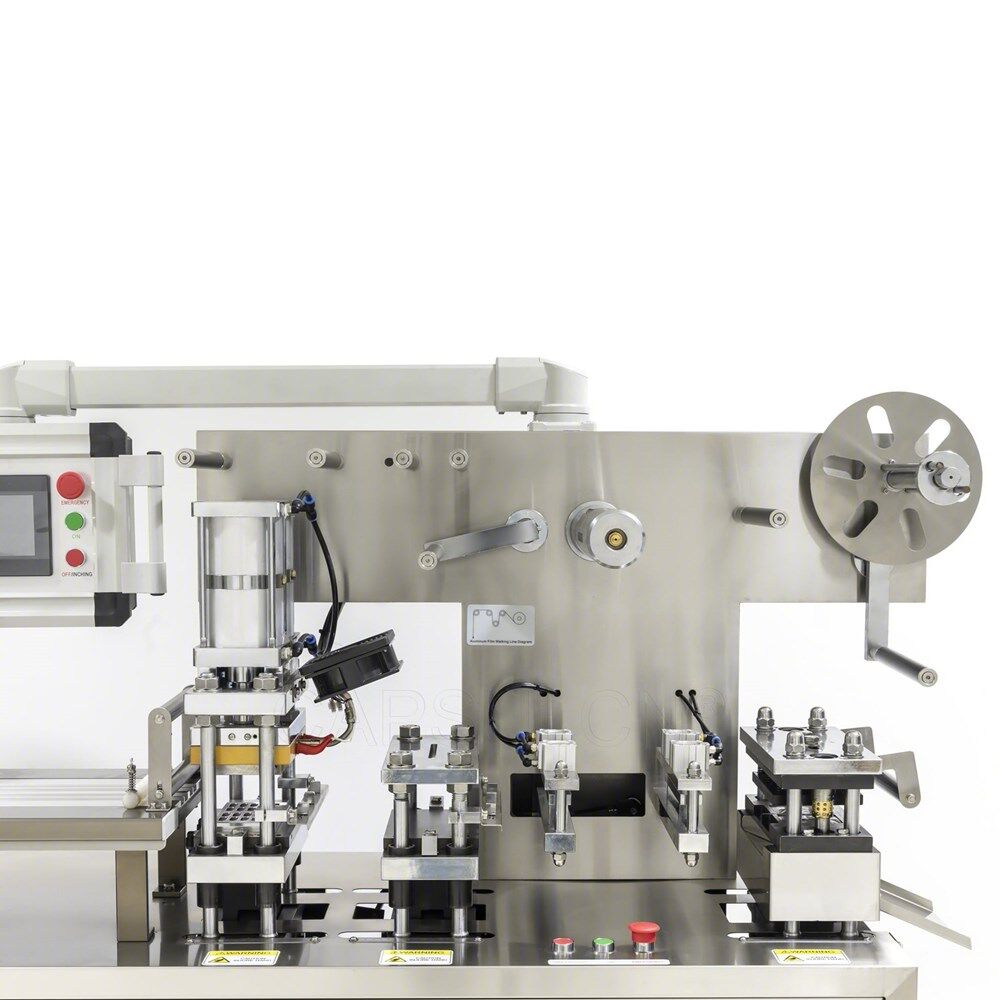

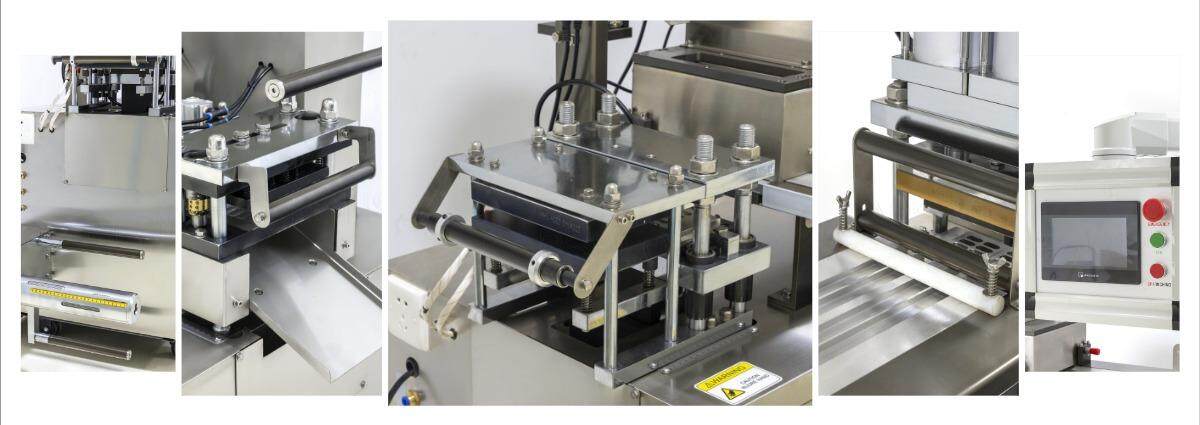

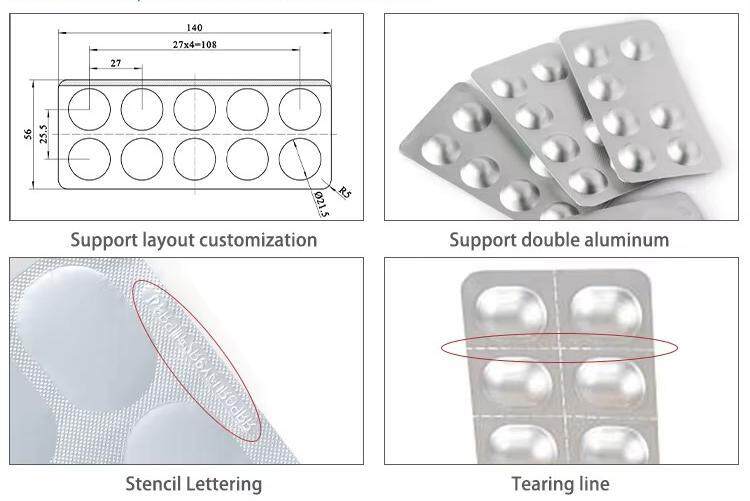

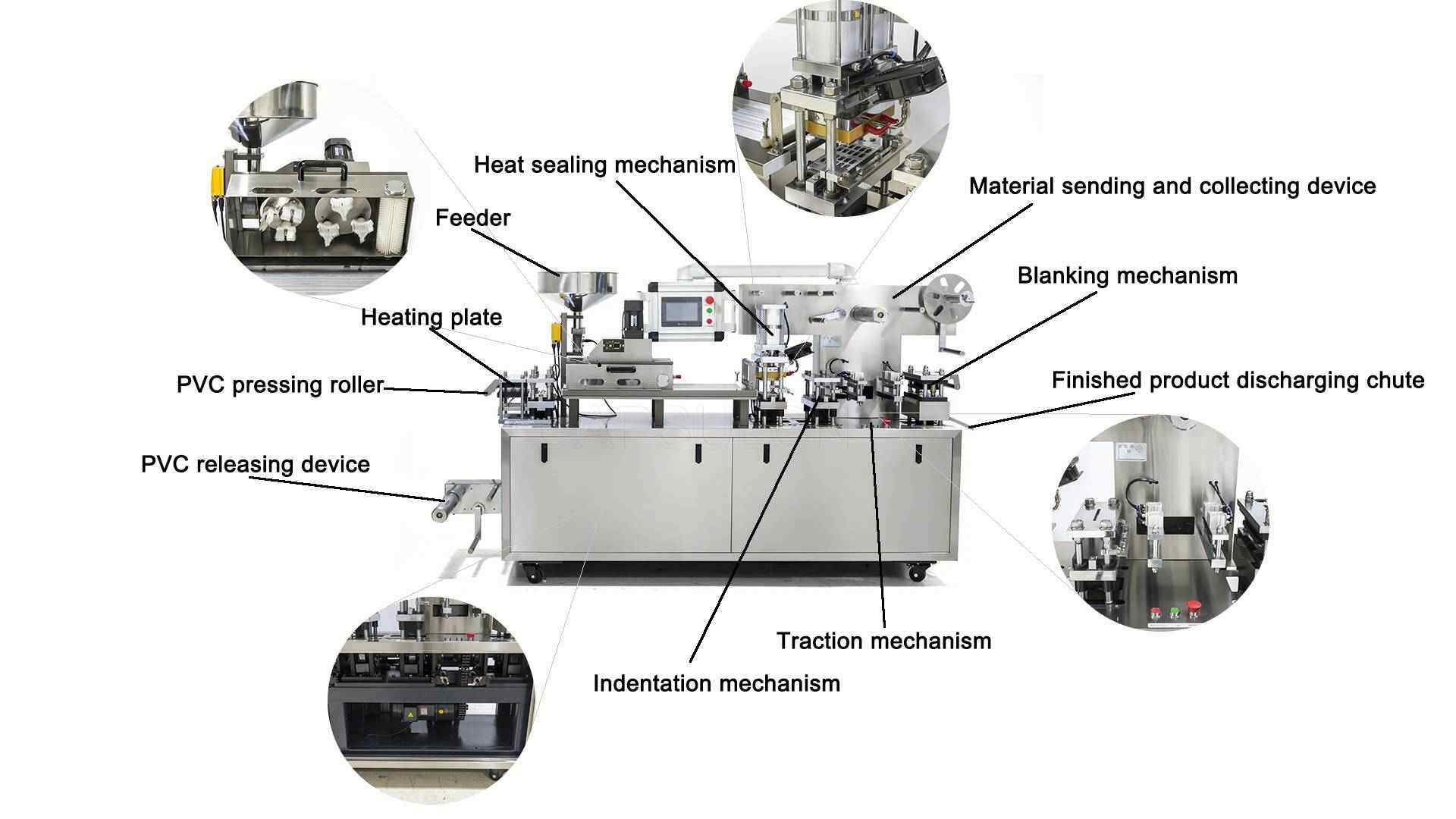

The DPP-140 aluminum-plastic blister packaging machine uses a flat heating plate for heating, and heats the PVC sheet to about 105°C through positive pressure to form the desired shape. The equipment can complete a series of actions such as heat sealing, batch number printing, creasing line pressing, automatic conveying, slicing and cutting, and automatic shutdown alarm. It is equipped with a variable frequency stepless speed regulation function, and the punching frequency can reach 10~55 times/minute. Using a spiral rod drive device, the packaging size of various sheets can be adjusted at will on the machine base rail as needed. The pneumatic roller traction device is controlled by PLC, with a simple structure and accurate operation, and the traction stroke can be adjusted within the range of 10 to 500 mm.

Feature:

- The flat heating method is adopted to ensure uniform heating of PVC materials.

- The variable frequency stepless speed regulation can meet the needs of different production speeds.

- The screw drive device supports flexible adjustment of packaging size.

- The pneumatic roller traction system is precisely controlled by PLC to improve efficiency and accuracy.

- The positive pressure forming, heat sealing and creasing molds are easy to replace and reliably positioned.

- The filling rate exceeds 99.5% when equipped with a universal feeder, and an optional dust suction interface can be installed to reduce dust during the feeding process.

- The equipment is compact and light, which is easy to transport and maintain.

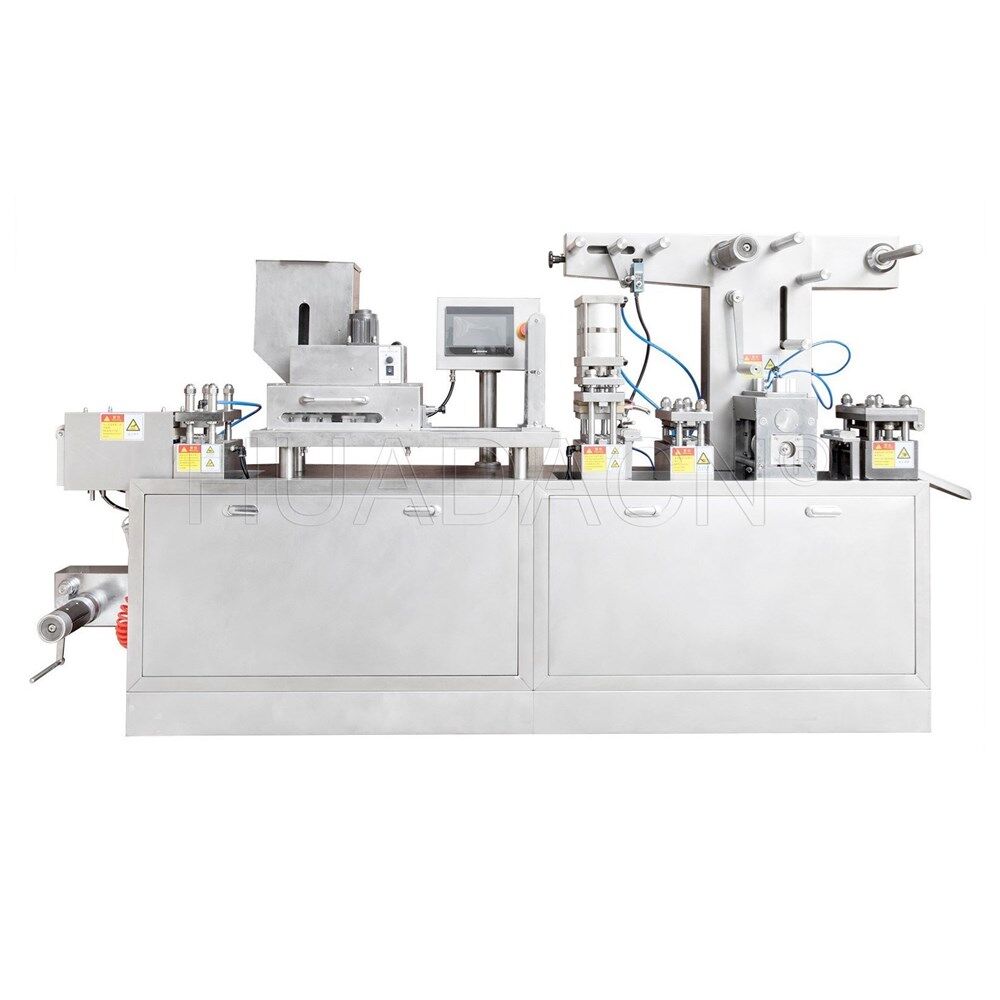

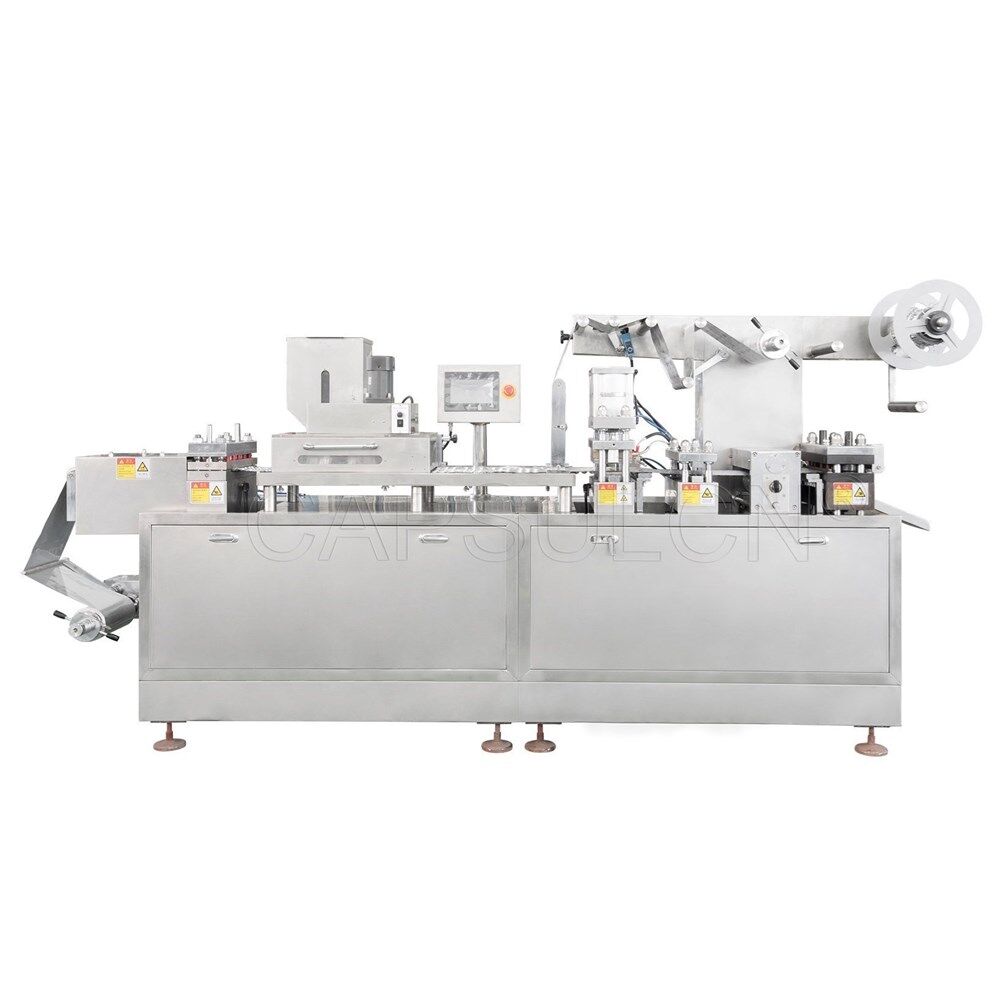

Simple Display:

Specifications

| Model | DPP-140 |

|---|---|

| Cutting frequency | 10-50 times/min |

| Capacity | 7200strip/h |

| Max shaping areas and depth | 140x120x28mm |

| Air pressure | 0.4-0.6Mpa |

| Power supply | 380V/220V 50Hz |

| Main motor power | 1.1kw |

| PVC hard pieces | 0.15-0.5*140mm |

| PTP aluminum foil | 0.02-0.035*140mm |

| Dialysis paper | 50-100g*140mm |

| Mould cooling | tap water or back water |

| Machine dimensions | 2050mm×526mm×1320mm |

| Net weight | 960Kg |

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Blister Packing Machine BM-Ⅳ

Blister Packing Machine DPP-160

Blister Packing Machine DPP-250

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche