Liquid Pouch Packaging Explained: Common 5 Types & 6 Materials

Liquid pouch packaging is becoming increasingly popular across a variety of industries. It’s a flexible, lightweight, and often eco-friendly packaging solution for liquid products. This packing type also offers significant benefits over traditional rigid containers like bottles and jars. So lots of manufacturers choose it for packing their liquid products. If you are also interested, a thorough understanding is a must.

What is Liquid Pouch Packing?

This is a packaging type used to contain and protect liquid products in flexible, convenient bags. It creates a strong barrier to keep liquids safe from external elements like air, moisture, and contaminants. And they are usually made from durable materials to prevent leaks. Furthermore, liquid pouch packaging often comes with user-friendly features like resealable caps, spouts, or tear notches. So it is easy for consumers to use and store the product without causing waste. These features also help in extending the product’s shelf life after opening.

Pouches can also be customized in various shapes, sizes, and colors. You can choose the most suitable one to match branding and product needs. This makes your products more attractive and helps them stand out on store shelves.

Applications of Pouch Packaging:

This packing type is used in various industries. Here are some of the main uses.

- Pharmaceutical and healthcare industry. They are always used for storing liquid medicines, syrups, health supplements, hand sanitizers, etc.

- Food and beverage industry. Common examples include juices, sauces, yogurt, cream, soups, etc.

- Personal Care and cosmetics. pouches are used to package liquid shampoos, conditioners, lotions, and liquid soaps. These pouches can be resealed, making them ideal for both single-use and refillable purposes.

- Industrial Liquids. They are are used for storing lubricants, cleaning solutions, and other liquid chemicals. Their durable, leak-proof construction makes them suitable for handling harsh liquids.

Five Types of Liquid Pouch Packaging

Liquid pouch packaging comes in various forms, each designed for specific uses and industries. These types differ in their structure, functionality, and features. Here are some popular types for your reference.

Stand-up Pouches

This is the most common type of liquid packaging. It has a bottom gusset. So it can stand upright on shelves for display. This design makes the package stable and attractive for retail products. Stand-up pouches often have resealable closures like zippers or spouts. This lets consumers use the product multiple times without leaking or contamination. Therefore, stand-up pouches are perfect for items like juices and sauces.

Spouted Pouches

This type is equipped with a nozzle or spout at the top and a wide, flat base. The spout can be screwed or snapped shut to stop liquid from leaking, making it good for reuse. The spout can also be resealed like stand-up pouches. It is convenient for on-the-go consumption. These are commonly used for beverages, sauces, liquid detergents, and baby food.

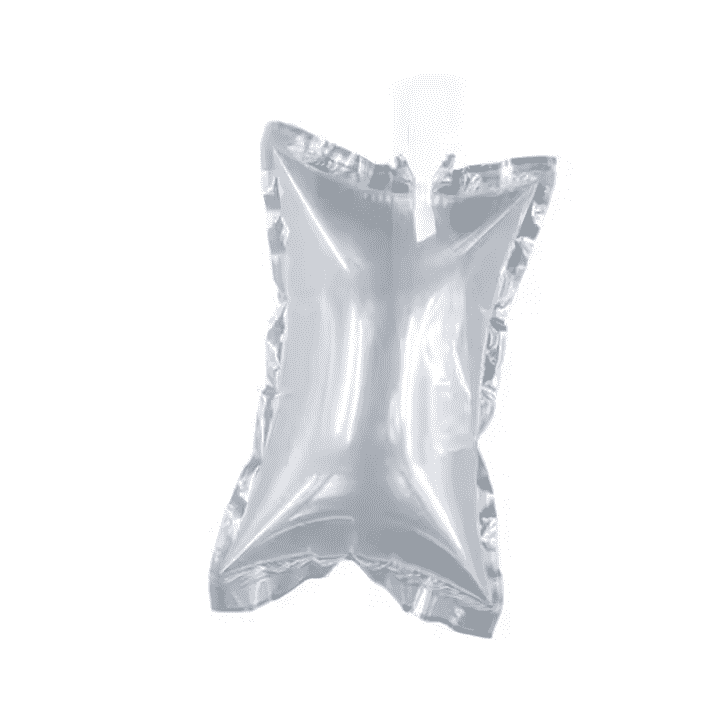

Pillow Pouches

As the name suggests, pillow pouches resemble a pillow when filled. These pouches are typically sealed on three sides: two vertical edges and one horizontal edge. The fourth side is used for filling and then gets filled. Unlike the former two pouches, pillow pouches do not have a bottom gusset. So they do not stand upright on shelves. They are typically designed for single-use, so once the package is opened, it is not resealable. If you want to produce sauces or condiments, pillow pouches are a good choice.

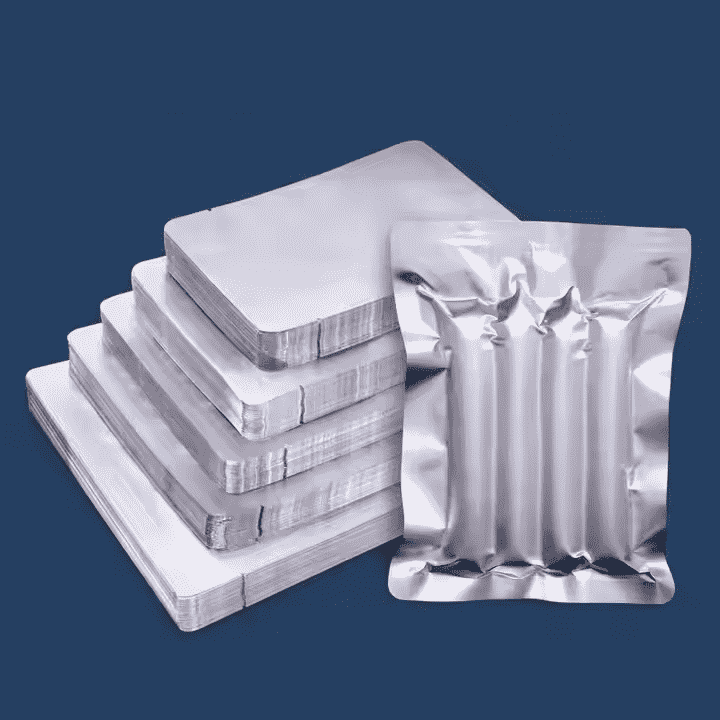

Flat Pouches

Flat pouches are also known as 2-side seal or 3-side seal pouches. They leave one side open for filling the liquid product. They can lie flat once they are filled. This makes flat pouches compact and easy to stack and transport. Same as pillow pouches, this type can’t be resealed, either.

Flat pouches are usually small and thin. It makes them ideal for packaging small liquid volumes, such as sauces, shampoo samples, liquid medicine, etc. In addition, there are many shapes of flat pouches to choose from. The most common shapes are rectangular and square. You can also customize the shapes to meet your production needs. For example, flat pouches in personal care may mimic the shape of a product bottle for more attraction.

Retort Pouches

Retort pouches are specially designed for products that undergo heat processing. They are typically for sterilizing and extending shelf life, without the need for refrigeration. They can withstand the high temperatures used in sterilization (usually over 120°C). It makes them suitable for cooking or preserving food directly in the packaging. So they are commonly used for ready-to-eat meals like soups, stews, sauces,etc.

Retort pouches are made with layers of flexible materials. Typically, they have an outer layer of polyester for durability and printability. A middle layer of aluminum foil act as a barrier against light, moisture, and air. And an inner layer of polypropylene is included, which is heat-sealable and food-safe. They are usually sealed with heat healing to ensure a leak-proof and airtight package.

Six Common Materials to Make Liquid Pouch Packing

The materials for liquid pouch packaging need to have several key features. They include leak proof, durability, heat-resistance, moisture-resistance, and safe for food. Common liquid pouch packaging is usually made of multiple layers of materials. Each of them has a different function to ensure the safety and shelf life of the liquid product.

PE

PE is a widely used plastic material in liquid packing. It can directly contact with liquids, so It is often applied for the inner layer of pouches. PET is ideal for packaging drinks, food, or chemicals. It also has good sealing and flexibility, making it easy for filling operations.

PP

PP is usually used for the outer layer of pouches. Because it has strong chemical resistance and mechanical strength, along with good transparency. PP can withstand high temperatures, so it is suitable for packing goods that require microwave heating or high-temperature sterilization. This material is also good at resisting corrosion from chemicals like acids and alkalis. Therefore, many manufacturers use it to hold chemical liquids or oily products.

PET

PET features good strength, stiffness, and high barrier properties. So it is often used as the outer packaging layer. This strengthens the pouch and makes it less likely to break or wear out. PET also has good moisture and gas barrier properties, preventing oxygen and moisture from entering. It helps extend the product's shelf life. With good stretch resistance, PET is ideal for printing. It keeps patterns clear and does not fade easily. PET is often used for packaging acidic liquids, dairy products, or food that requires high protection, like juice and sauces.

Aluminum Foil

Aluminum foil is commonly used as the middle layer in pouch packaging. Because it has excellent barrier properties. This material can almost completely block oxygen, light, and moisture. So it is ideal for packing liquids sensitive to light or that require long-term storage. Aluminum foil features high heat resistance, suitable for products that need sterilization at high temperatures, such as ready-to-eat meals.

Polyamide

Although more commonly used in solid packaging, PA is also applied in some liquid pouches. It features high puncture resistance and durability, suitable for products that needs good strength and protection. It helps prevent the packaging from breaking during heat treatment or transportation. This helps extend the product's shelf life. If your products like soups require high temperature and pressure for sale, PA is a good material for packing. However, compared to other materials, PA costs much higher.

EVOH

EVOH has a high barrier against gases, making it a great material for products sensitive to oxygen, like functional drinks. It is usually not used alone but combined with other materials like PE or PP. It is more often found in high-end food and functional drink packaging, especially for products that need to stay fresh for a long time.

The End

Pouch packing for liquid offers a versatile, efficient, and eco-friendly packaging solution. It not only enhances product preservation but also minimizes waste and reduces transportation costs. If you want to make liquid pouch packaging, a high-quality liquid filling machine is a must. If you don’t know how to choose a suitable one, contact iPharMachine for help.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche

Recently viewed