Video

Introduction

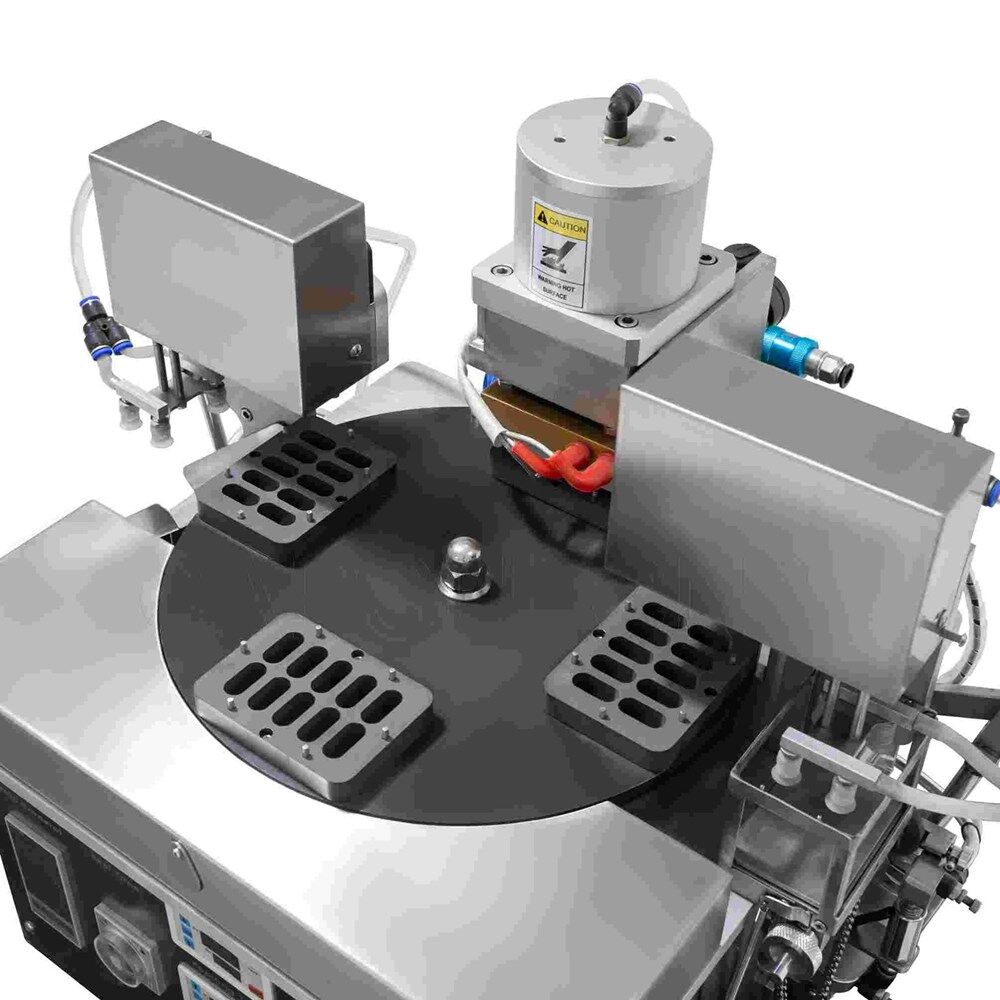

The rotary pneumatic sealing machine ABM-720 is designed with a rotating disk structure and is equipped with a reduction motor and a swing arm to complete the work steps required at each workstation. It mainly includes four actions: manual filling of blister, aluminum foil transfer, pneumatic heat sealing and instantaneous air blowing and discharge. The machine has a simple and elegant appearance and is easy to operate, making it suitable for small businesses. Its key features include a clear and concise operating interface, an intelligent temperature controller for precise temperature control, and a compact size for easy movement, made of lightweight lead alloy material.

Features

- Clear and concise interface for easy operation by customers.

- Precise temperature control using an intelligent temperature controller.

- Compact size for easy mobility, made of lightweight lead alloy material.

Specifications

| Model | SCD-600 |

|---|---|

| Power supply | AC 110~220V 50/60Hz |

| Heat Sealing Temperature | 100-120°C |

| Air Pressure | 0.6-0.8MPa |

| Displacement | 0.12m³/min |

| Heat Sealing Time | 4-5 seconds |

| Air Pressure Caliber | φ10mm |

| Power | 300W + 25W |

| Net Weight | 50kg |

Rmark

- Please verify the voltage requirement stated in the machine manual.

- After using the machine, make sure to turn off the power switch and unplug the power plug.

- Use a grounded socket and ensure reliable grounding.

- Do not allow water or flammable liquids to enter the machine.

- Do not reach your hand into the machine during operation to avoid burns or injuries.

- If any abnormality is observed during operation, immediately stop using the machine and have it inspected and repaired by a professional technician.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

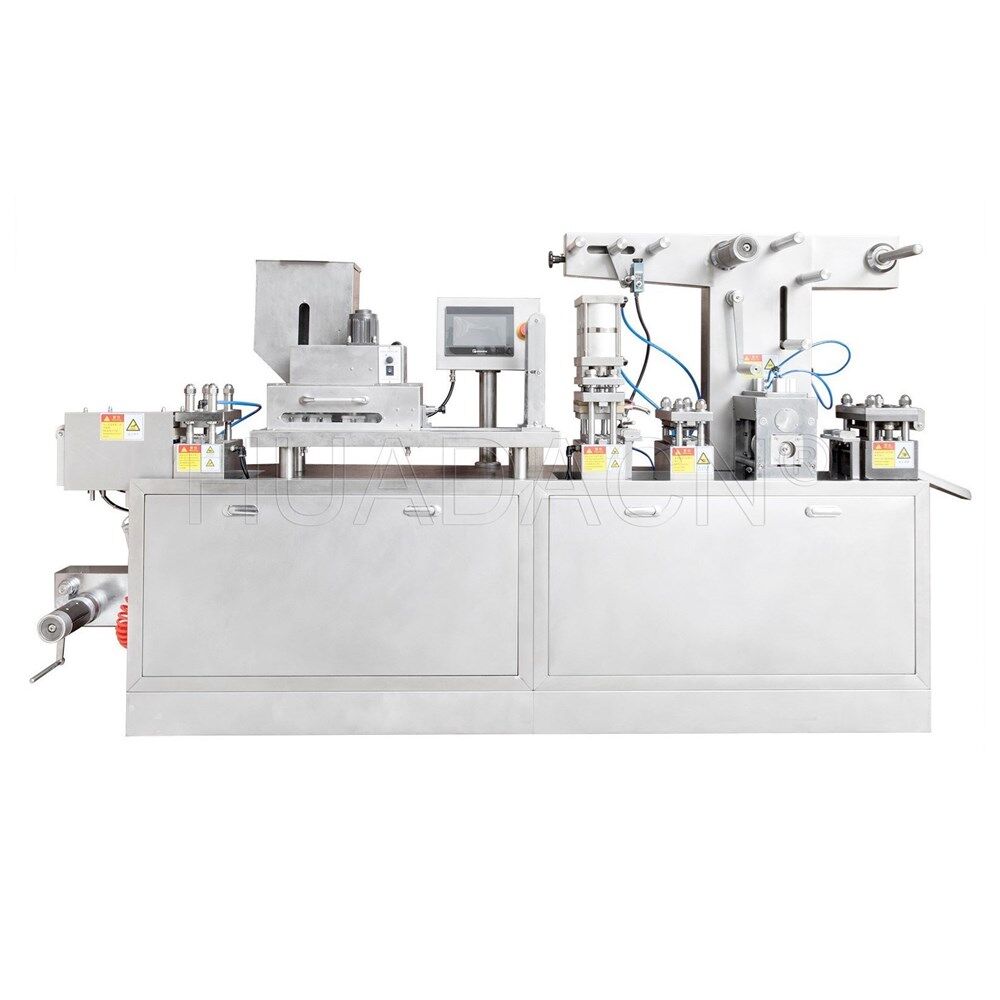

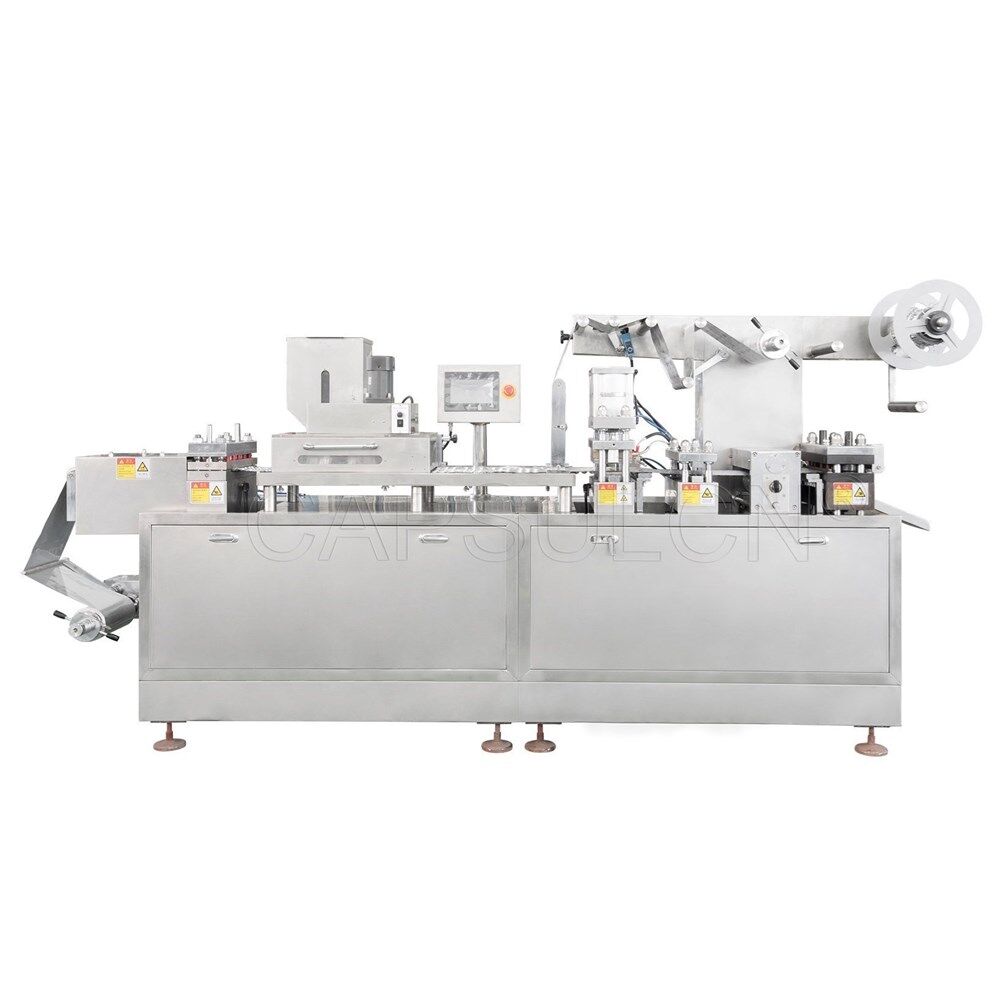

Blister Packing Machine BM-Ⅳ

Blister Packing Machine DPP-160

Blister Packing Machine DPP-250

Blister Packing Machine DPP-88

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche

Recently viewed