Video

Introduction

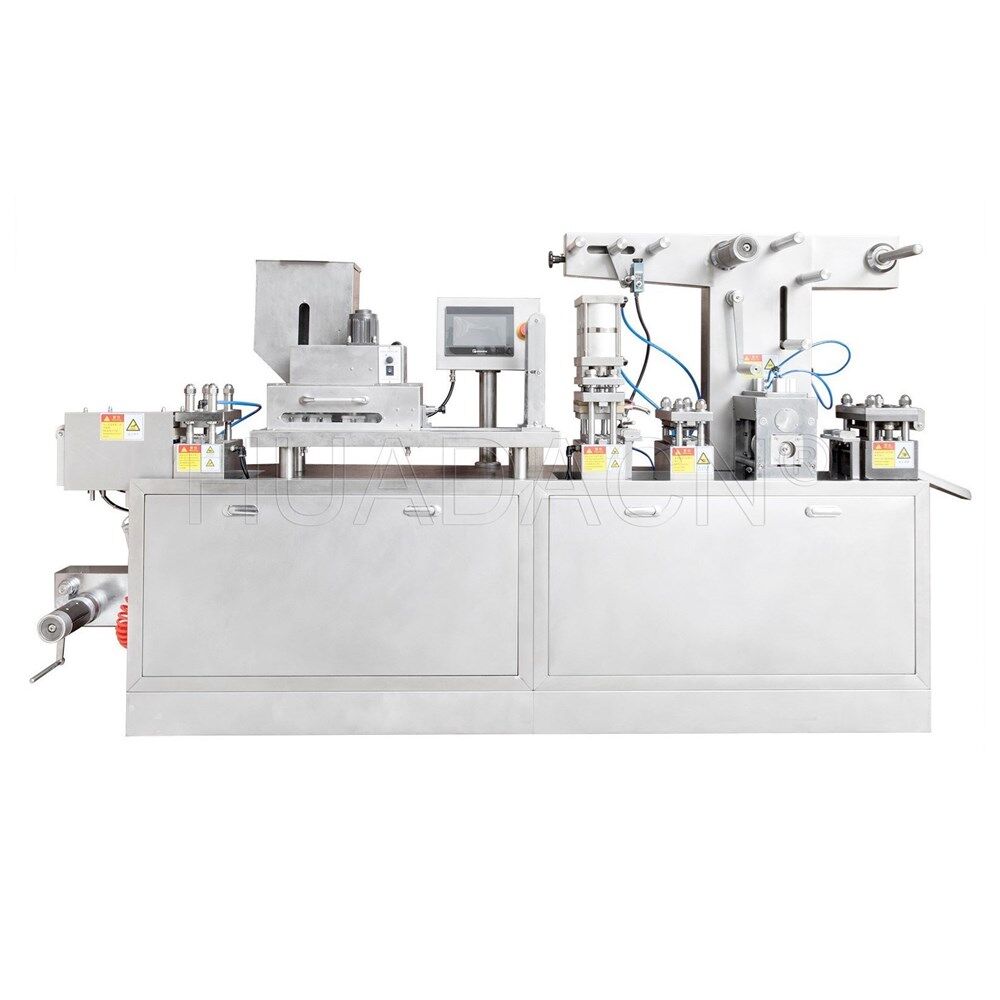

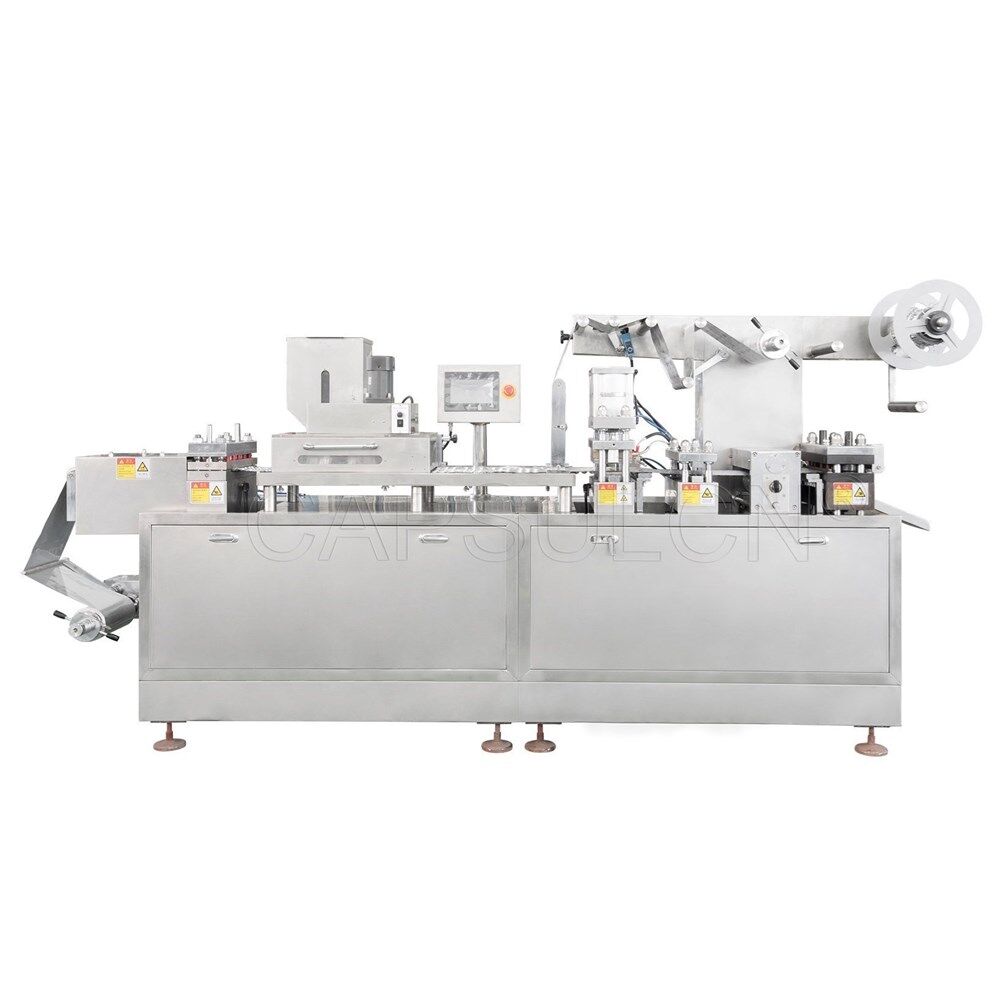

This machine is mainly suitable for single or multiple (collective packaging) automatic packaging of various box-type items in the industries of medicine, food, health care products, tea, cosmetics, gifts, stationery, audio-visual products, etc. It can replace the box-in-paper , and can reduce packaging costs by about 95%. The packaging of this machine can also play the role of anti-counterfeiting, moisture-proof, dust-proof, etc., and improves the product grade and increases the added value of the product.

Feature

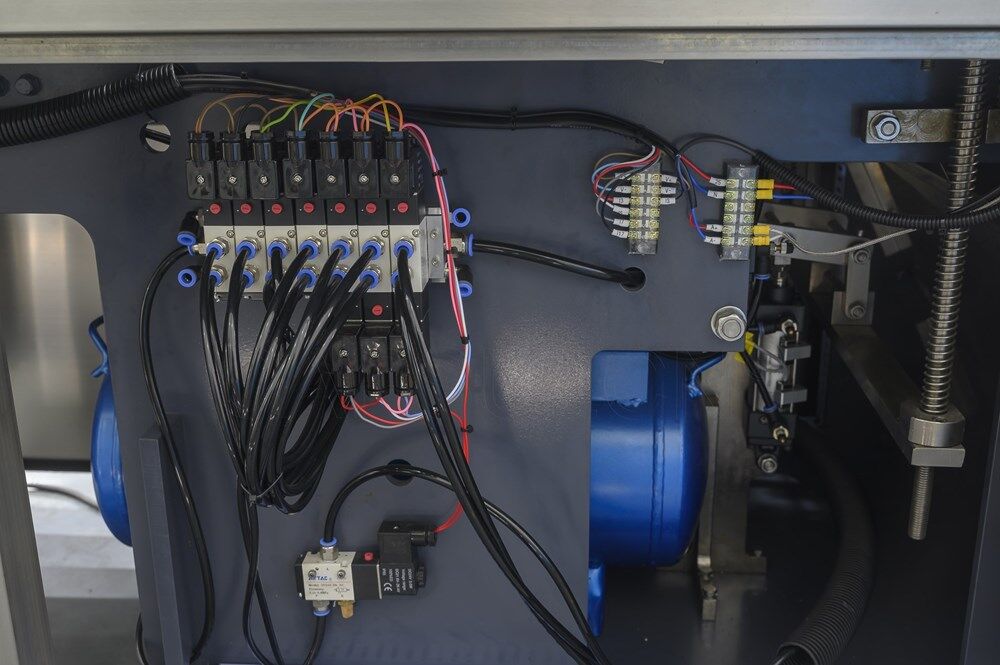

- Using man-machine interface, PLC control, fault diagnosis prompt.

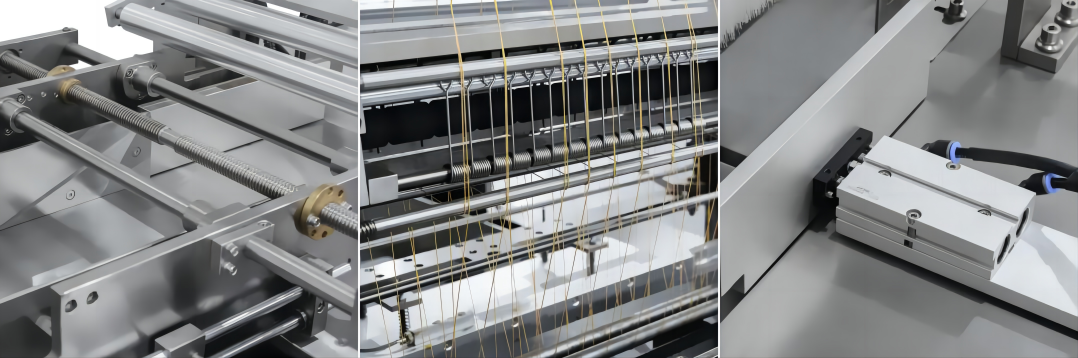

- The servo motor is used to automatically lower the film, the speed and length can be adjusted, and the film is lowered smoothly and accurately.

- Driven by a servo motor, the operation is stable, the synchronization is accurate, the adjustment is convenient, and the sealing is firm.

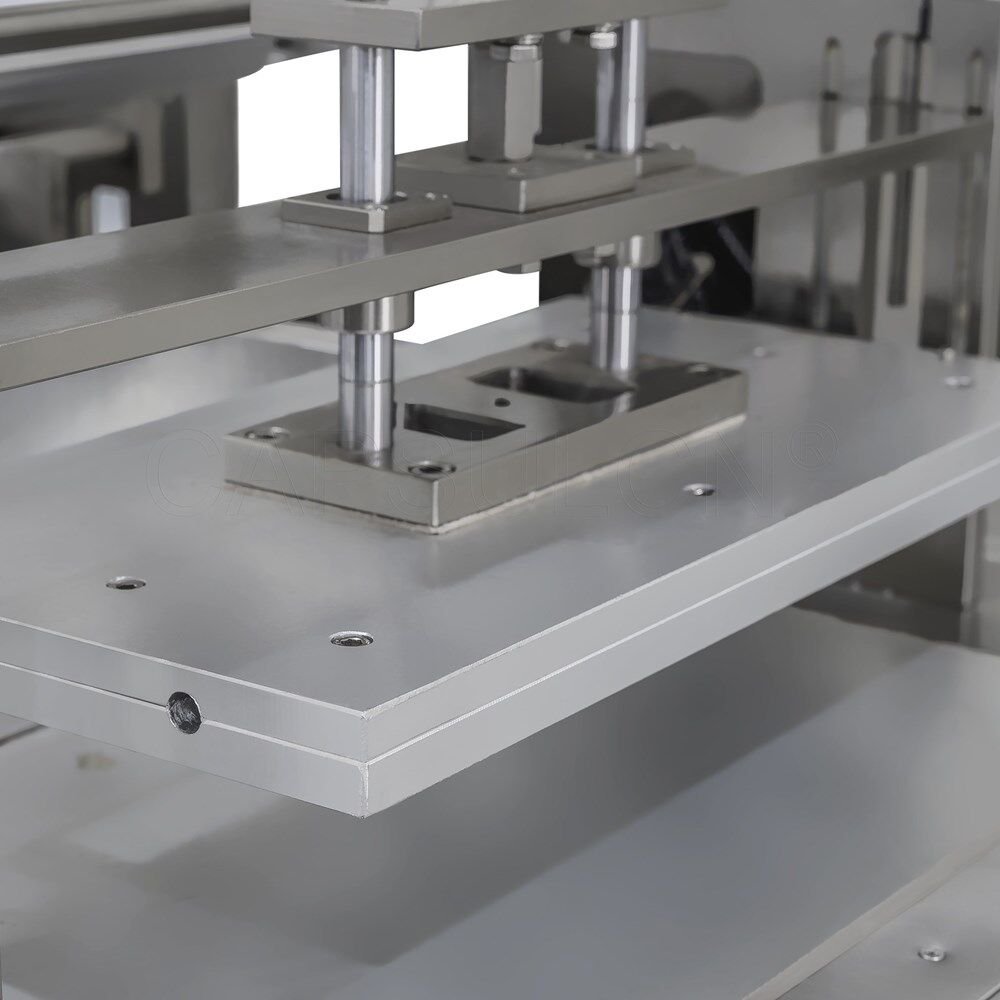

- Compact structure, easy operation and maintenance, complete safety protection.

- Purely mechanical main transmission design, the speed can reach up to 40 boxes/min, stable operation and extremely low failure rate.

- The operation is simple, the variety can be replaced quickly, the maintenance is convenient, and the normal production can be resumed in a short time in case of failure.

- The pushing part is driven by sprockets and chains, and the servo motor is used to control the film feeding. The box pushing mechanism is equipped with an overload protection device, which reduces the failure rate.

- The conveying function can be divided into linear (180 degree) conveying or vertical (90 degree) conveying according to the limitation of the site.

Specifications

| Model | TMP-400S |

|---|---|

| Packaging Materials | OPP,BOPP,PVC |

| production capacity | 10-40 (bags/minute) |

| Package Size | L(50-400)×W(40-220)×H(10-90)mm |

| power supply | AC380V 50HZ 6.5KW |

| working pressure | 0.5-0.7 Mpa |

| Exhaust volume | 400L/min |

| Total Weight | 850kg |

| Dimensions | 2450*1000*1850mm |

| Conveyor table size | Standard 1500*240*870mm |

Remarks

- According to the customer's requirements, it can be equipped with a stand-up device or a stacking device to meet different packaging needs.

- The rocker-type pushing device is adopted, and attention should be paid to avoid overloading during use, so as not to affect the normal operation of the equipment.

- The servo motor drives the film conveying, and it is necessary to pay attention to the accuracy of the signal to ensure that the conveyed film length meets the requirements.

- When using the equipment, follow the operating procedures to ensure the normal operation of the equipment and avoid malfunctions caused by misoperation.

- This equipment is suitable for single-piece or multi-piece (collective packaging) automatic packaging of various box-type items in the industries of medicine, food, health care products, tea, cosmetics, gifts, stationery, audio-visual products, etc. When using it, it needs to be adjusted and adapted according to the characteristics and needs of the product.

- When using equipment, you need to pay attention to safety matters to ensure the safety of operators and equipment.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Blister Packing Machine BM-Ⅳ

Blister Packing Machine DPP-160

Blister Packing Machine DPP-250

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche