Video

Introduction

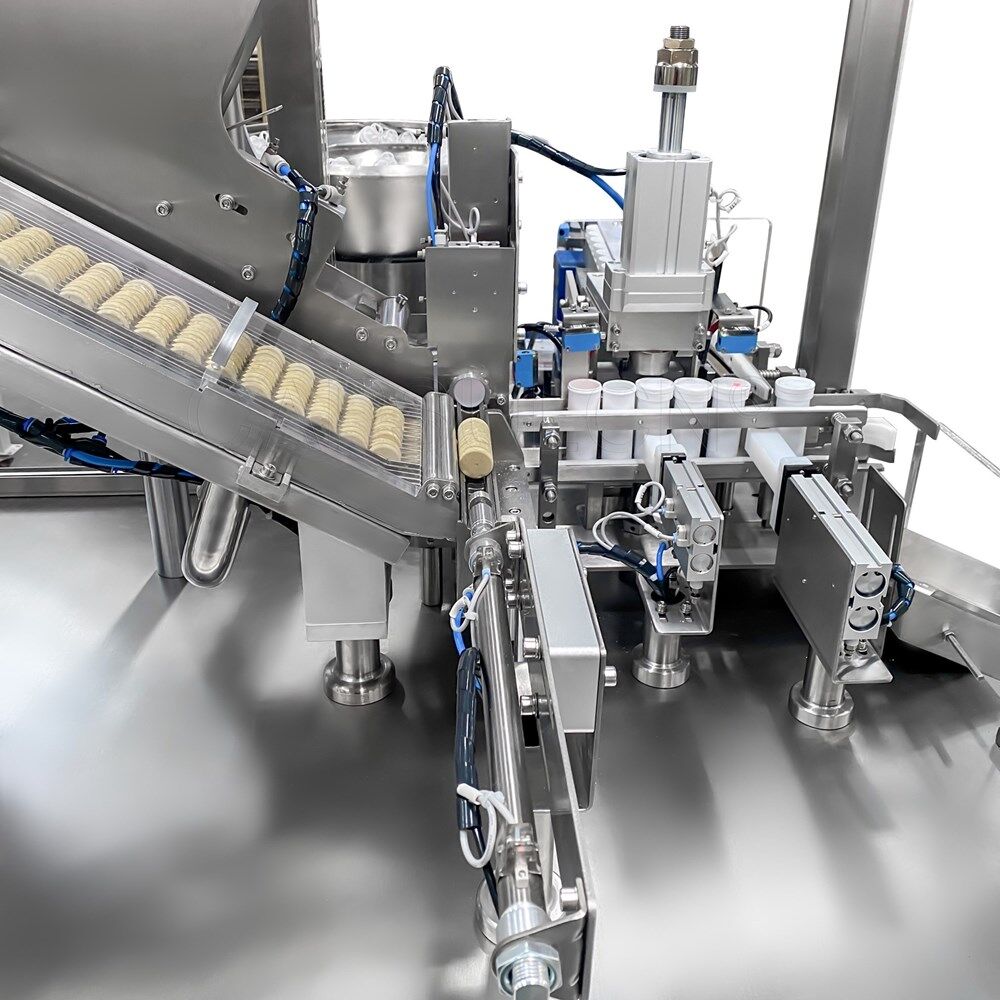

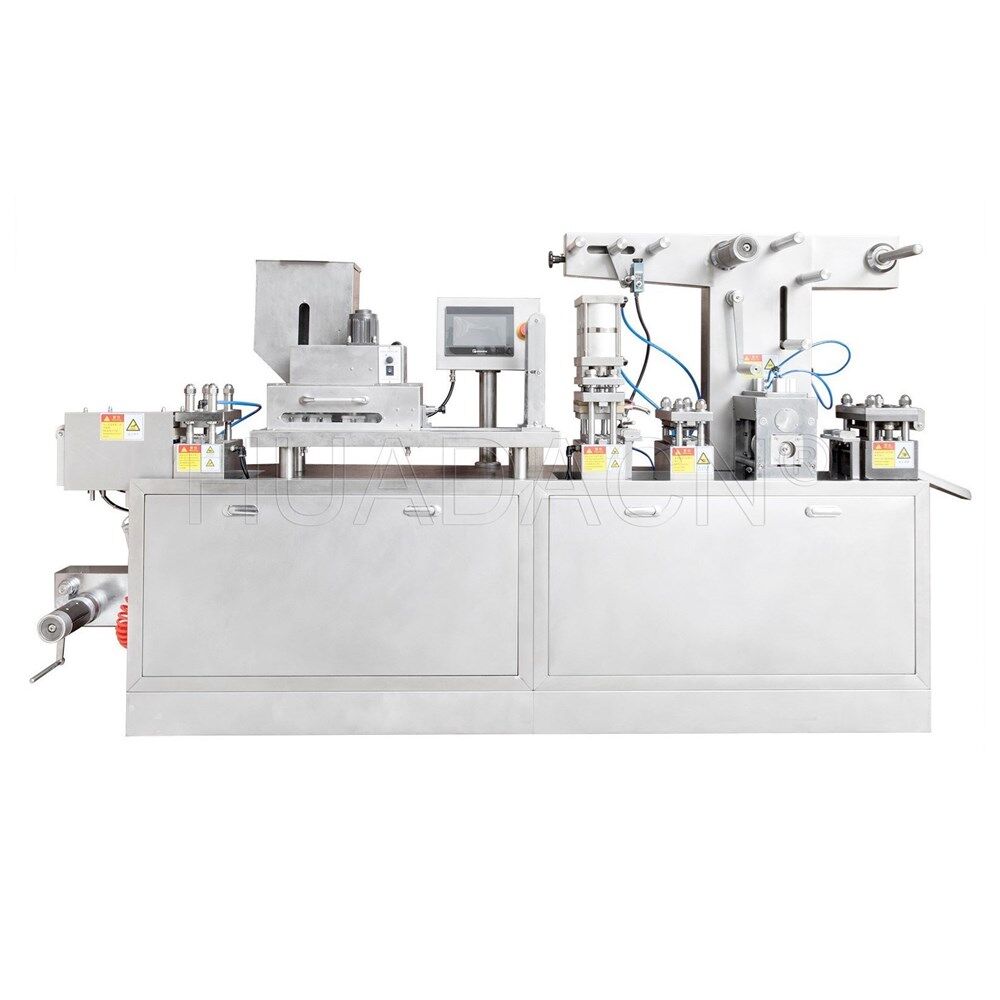

The CED-40A Tablet Bottling Machine for bobbin bottles is applicable to the packing of bigger and thinner tablets which are orderly fed into bobbin bottles/tube in a single row in an overlapping way. The device utterly adopts a PLC for centralized control. It is verified in fiber and photoelectric detection and other kinds of detection to have steady performance and reliably automatic operation. It can automatically give alarms and shut down in case of no tablets, bottles or covers. Its part in contact with the tablets is made of superior 316 stainless steel.which can fully requirement of GMP.

Feature

- Applicable to bigger and thinner tablets which are orderly fed into bobbin bottles/tubes in a single row in an overlapping way

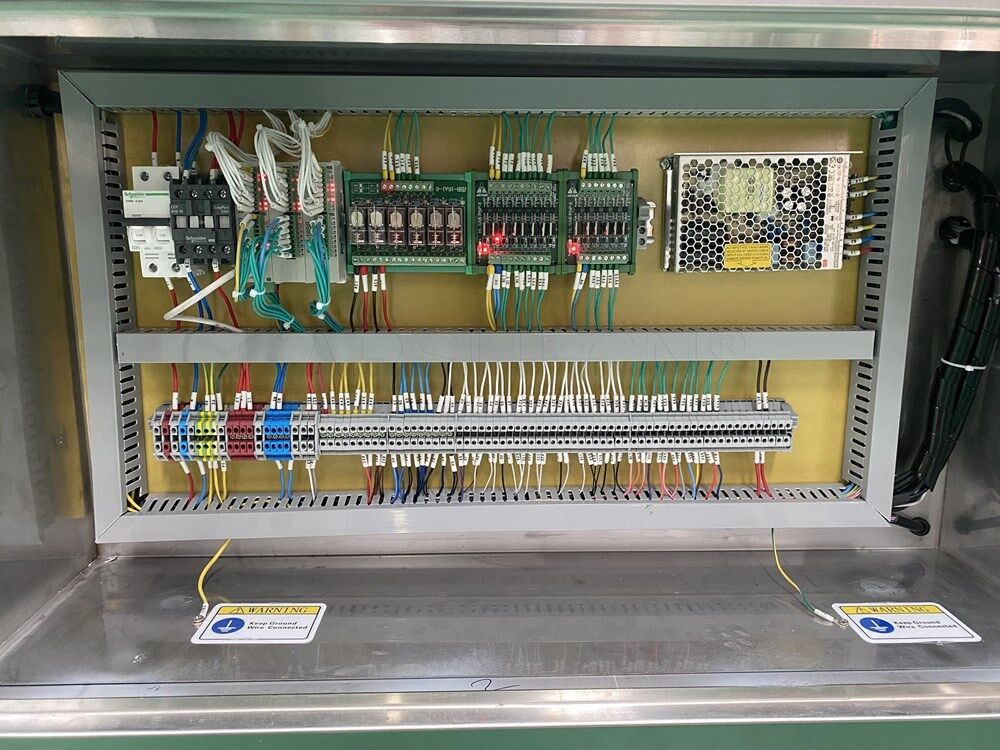

- Uses a PLC for centralized control, ensuring steady performance and reliable automatic operation

- Equipped with fiber and photoelectric detection and other kinds of detection for verification

- Automatically gives alarms and shuts down in case of no tablets, bottles, or covers

- Part in contact with the tablets is made of superior 316 stainless steel, meeting GMP requirements

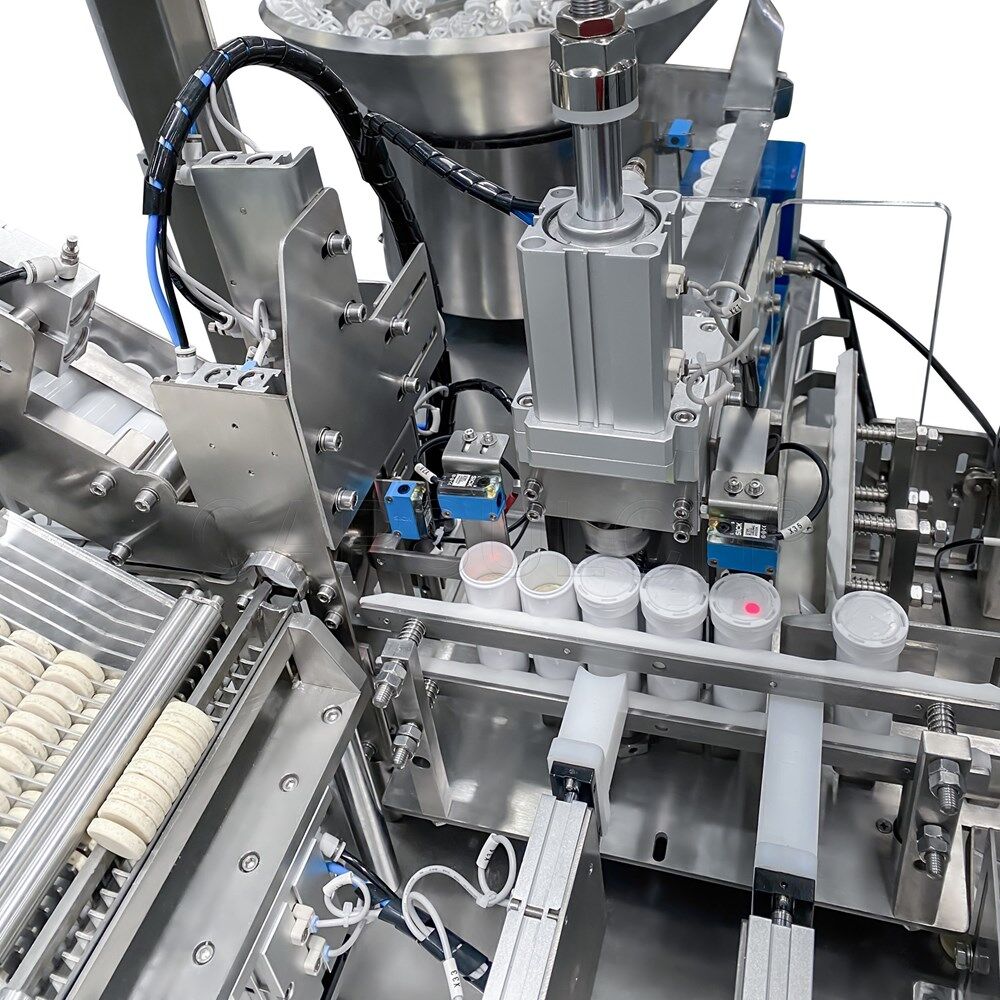

- Cap Vibrating System loads caps to the hopper and automatically arranges them to the rack for plugging

- Tablet feeding system puts tablets into the hopper and automatically sends them to channels for packing preparation

- Tube feeding unit puts tubes into the hopper and automatically sends them to the rack

- Cap Pushing unit pushes the cap and closes the tube automatically when the tube gets a tablet, with no tablet or tube resulting in no capping

- Controlled by PLC, cylinder, and stepper motor with an automatic multi-function alarm system.

Specifications

| Model | CED-40A |

|---|---|

| Output | 20 bottles/min |

| Tablet diameter | 25mm |

| Tablet thickness | 5.5mm |

| Number of tablets per loading | 12 |

| Purified compressed air | 0.5~0.6MP, usage: 0.28m3/minute |

| Voltage | 220V |

| Power | 1.5KW |

| Dimensions | 2400*1600*1800mm |

| Weight | About 480KG |

Remarks

- The machine plate and frame are made of steel and enamel paint, the platform cover is 304, and all the material touch with the tablet will adopt sus316l.

- The machine cannot clear all debris, so some debris needs to be manually cleared from the track. The machine will not press the bottle cap and automatically remove it if less than one piece is detected. It can also automatically reject when the cap is not installed on the bottle mouth.

- The machine is equipped with a vacuum interface, and the customer needs to prepare the vacuum cleaner. The interface diameter is 38mm.

- The operation process involves manually putting tablets into the hopper, which then enter the screening tablet section and are automatically arranged into orbit before entering the loading position.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

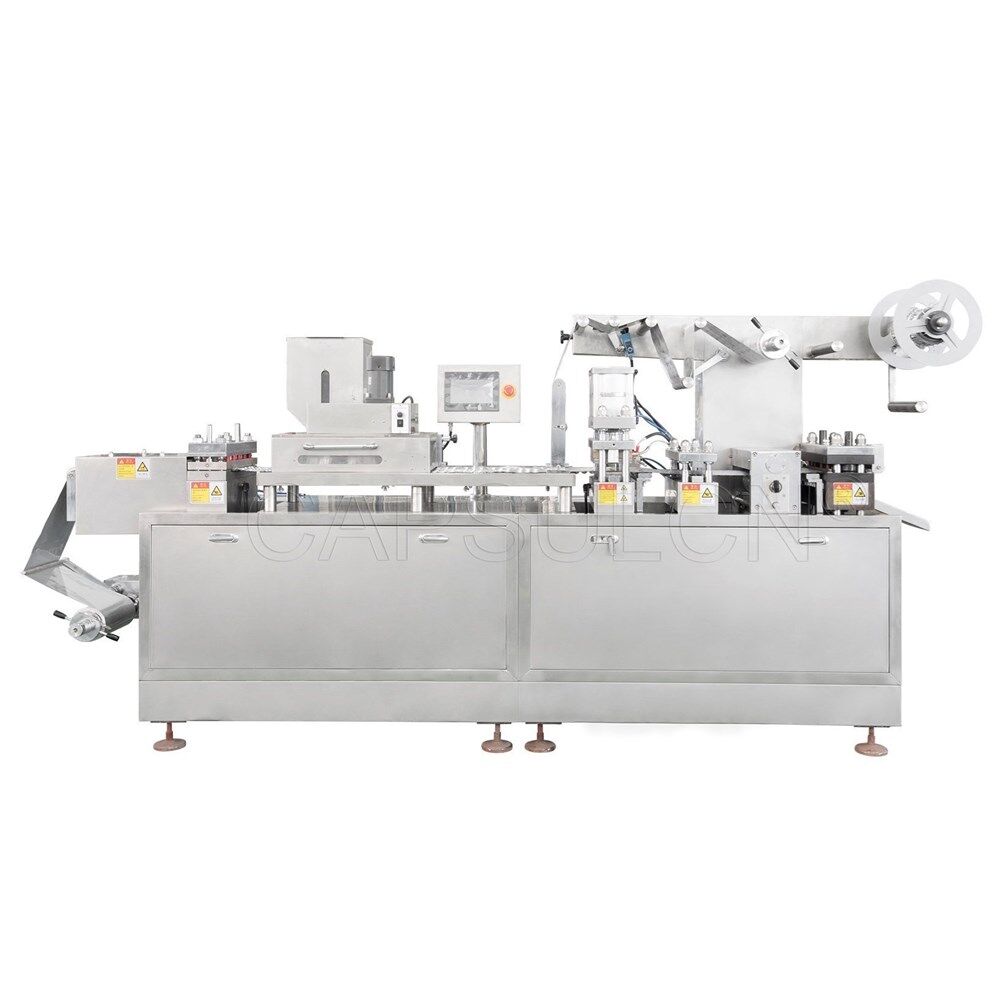

Blister Packing Machine BM-Ⅳ

Blister Packing Machine DPP-160

Blister Packing Machine DPP-250

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche