Video

Introduction

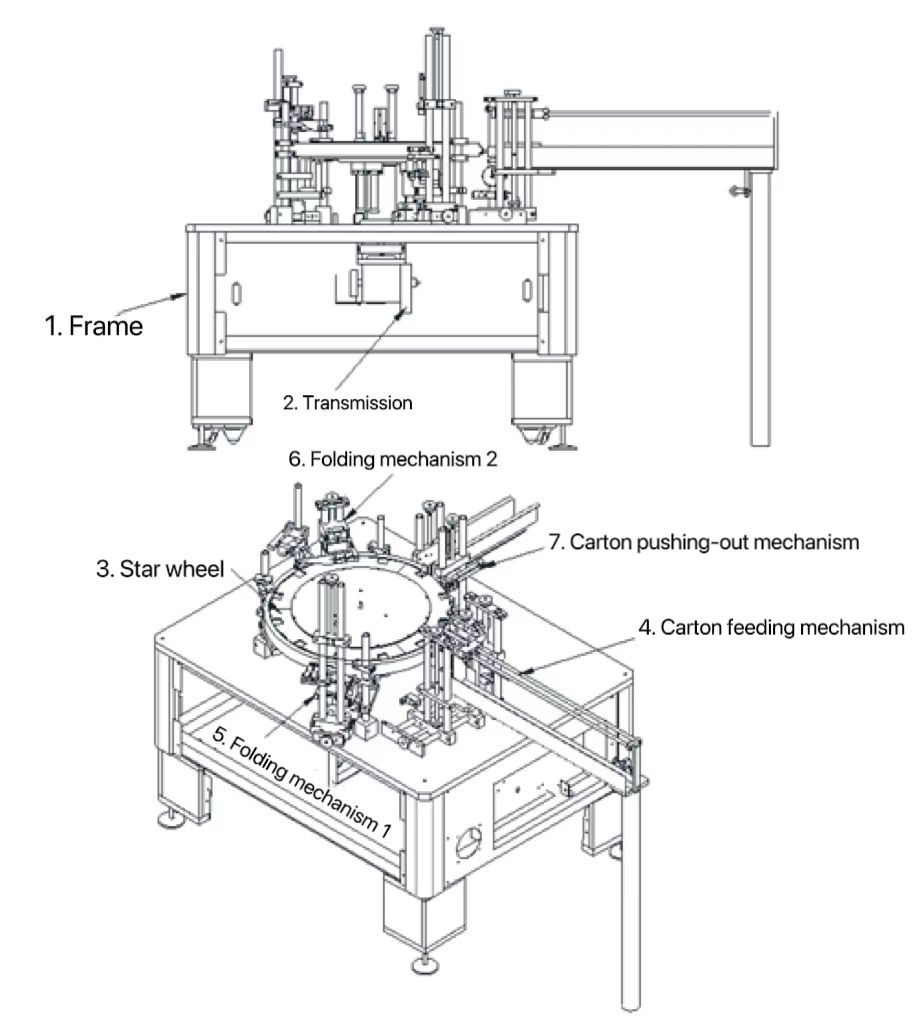

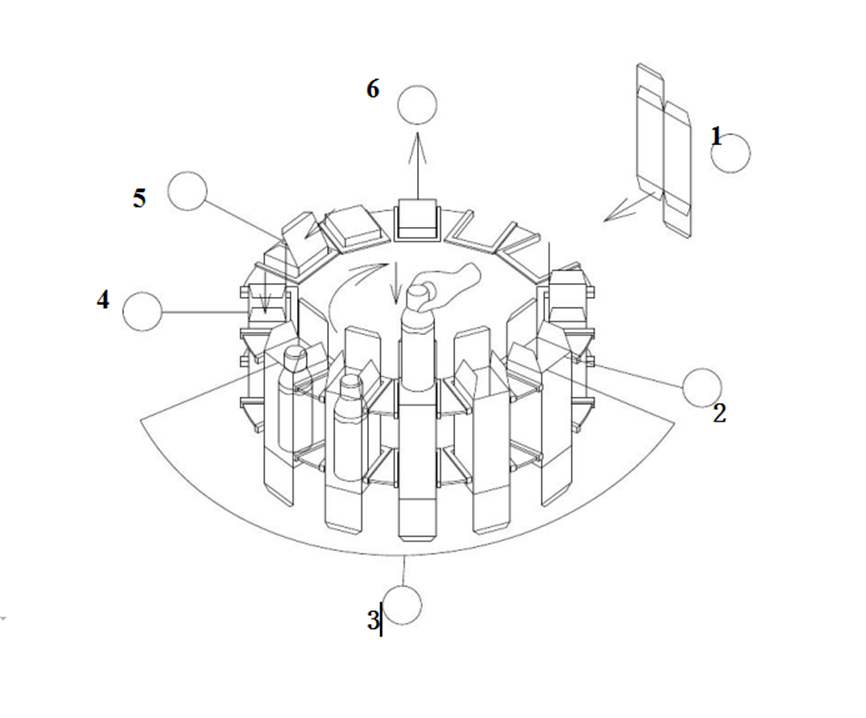

This machine uses vacuum suction cups to feed cartons into the star wheel. The empty cartons are rotated by the star wheel to the folding mechanism 1 to seal the bottom of the carton. After the finished product to be packed is manually placed into the carton, the star wheel rotates the carton to the folding mechanism 2 to seal the top of the carton. Finally, the completed product is transferred by the star wheel to the carton pushing-out mechanism for delivery.

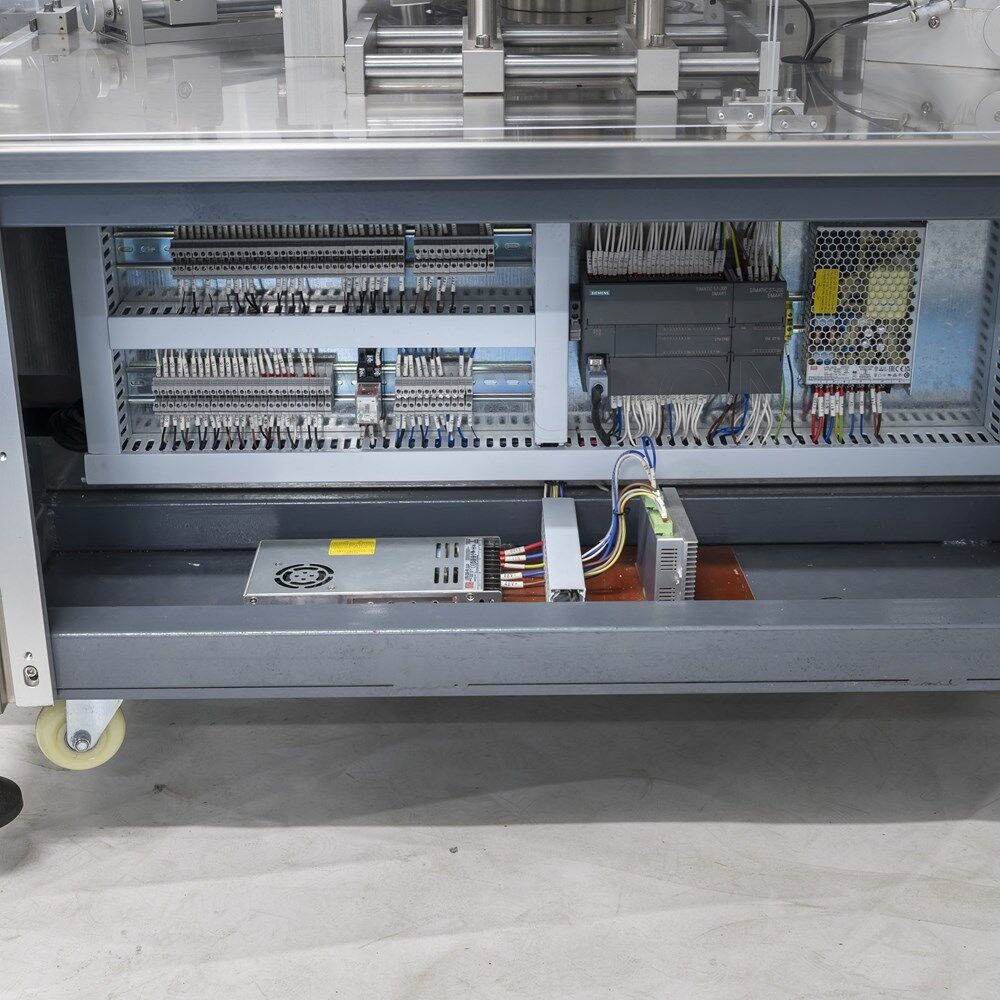

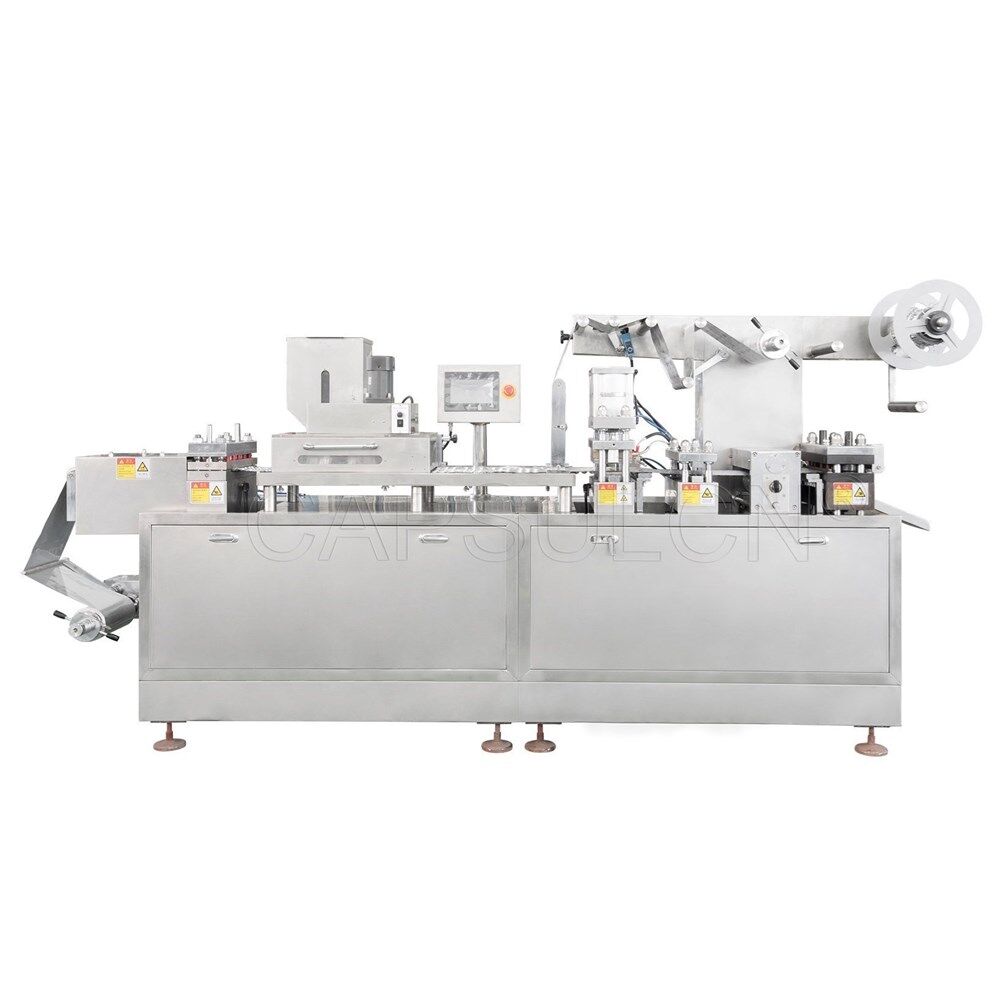

The machine consists of the following main parts:

Workflow Steps

-

The vacuum suction cup device on the carton feeding mechanism holds the carton and feeds it into the star wheel fixture, then a set of cylinders from below fold the inner small flaps.

-

After the carton is transferred to this station, the stopper cylinder on the ear folding mechanism 1 blocks the large ear, and the ear folding cylinder folds the large ear into the carton, followed by the flattening of the large ear by the ear pressing cylinder.

-

Place the desired items into the carton.

-

The rotating cylinder on the ear folding mechanism 2, together with the ear pressing rod, folds the inner small flaps on the top of the carton.

-

After the carton is transferred to this station, the stopper cylinder on the ear folding mechanism 2 blocks the large ear, and the ear folding cylinder folds the large ear into the carton, followed by the flattening of the large ear by the ear pressing cylinder.

-

After the finished product of carton folding is transferred to this station, a set of pushing cylinder pushes the finished product out of the star wheel.

Specifications

| Model | DZH-50S |

|---|---|

| Carton minimum dimensions | 60*20*20m/m |

| Carton Maximum dimensions | 200*80*80m/m |

| Production speed | 20-60 cartons/min |

| Power supply | 220V single phase;50/60Hz |

| Horsepower of motor | 1/4HP 15:1 |

| Air pressure consumption | 150L/min |

| Machine dimensions | 1750L*1200W*1500H |

| Machine Weight | 950kg |

Maintenance and Care for Machine

-

Keep the machine clean by wiping it regularly and occasionally tightening screws near the cylinder to prevent loosening.

-

In case of malfunction, analyze carefully and have relevant mechanics repair and troubleshoot. Do not adjust or dismantle components at will to avoid damaging the machine.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

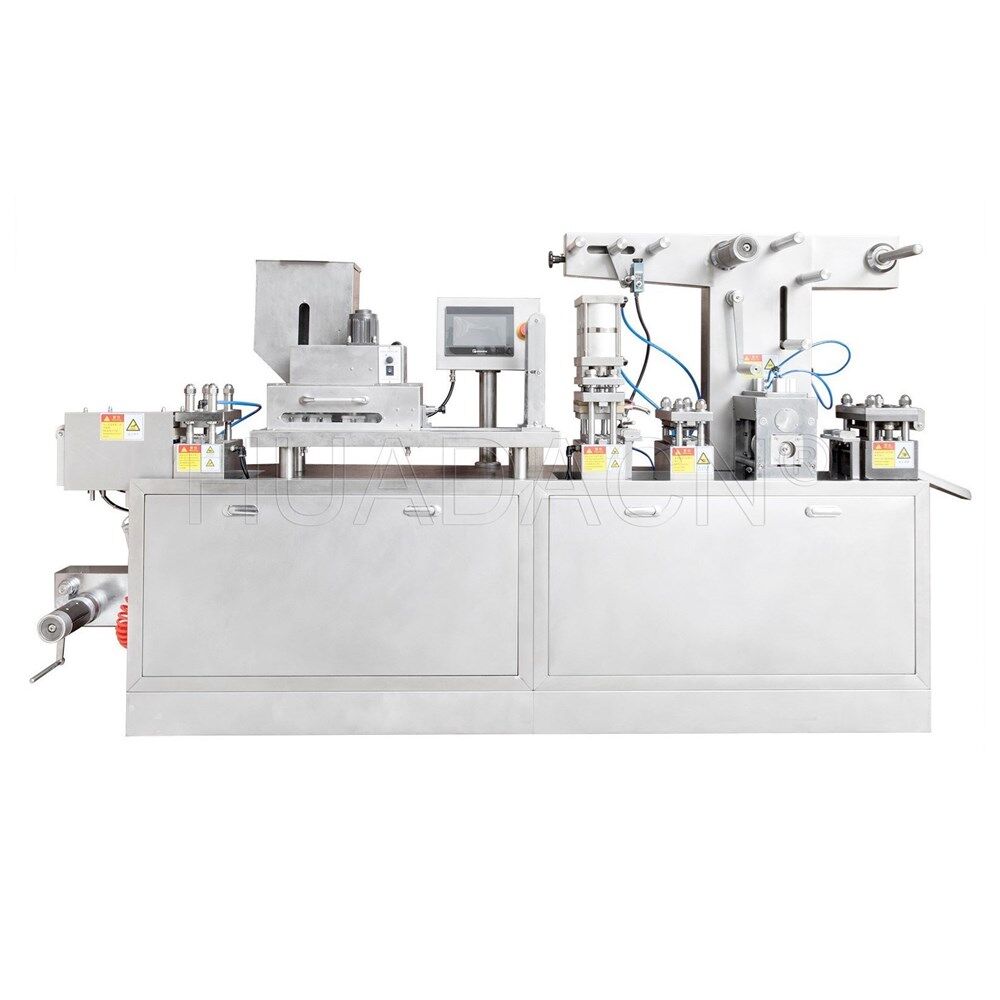

Blister Packing Machine BM-Ⅳ

Blister Packing Machine DPP-160

Blister Packing Machine DPP-250

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche